Menü

Order Picking and Outgoing Goods Inspection Speed Up Outgoing Goods Processes

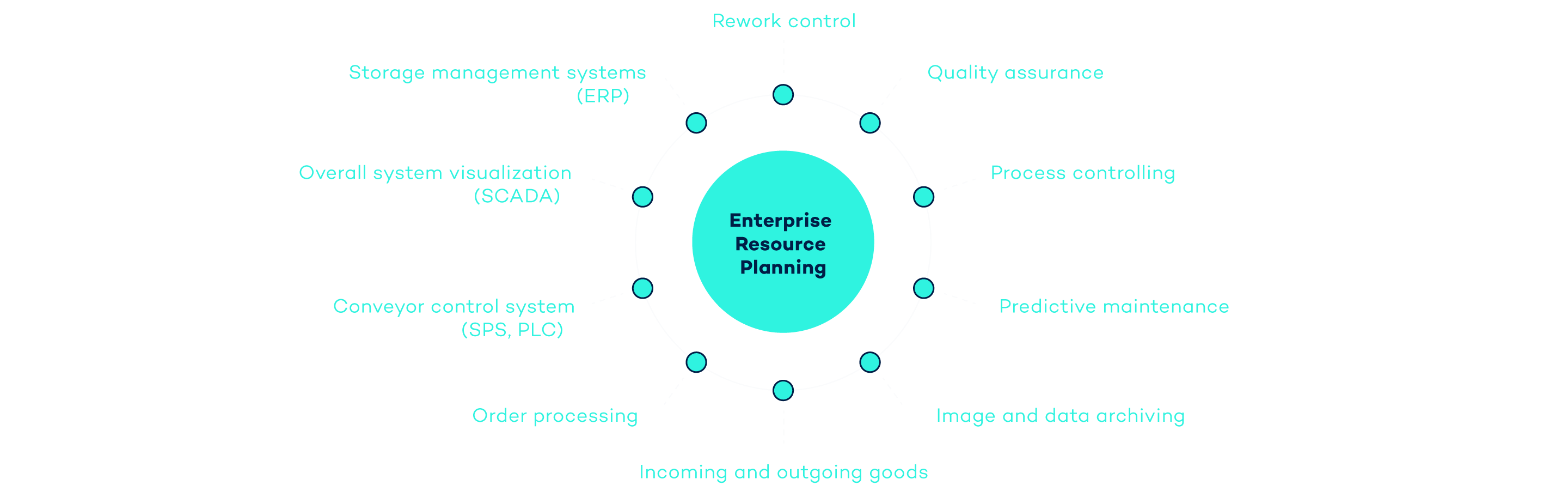

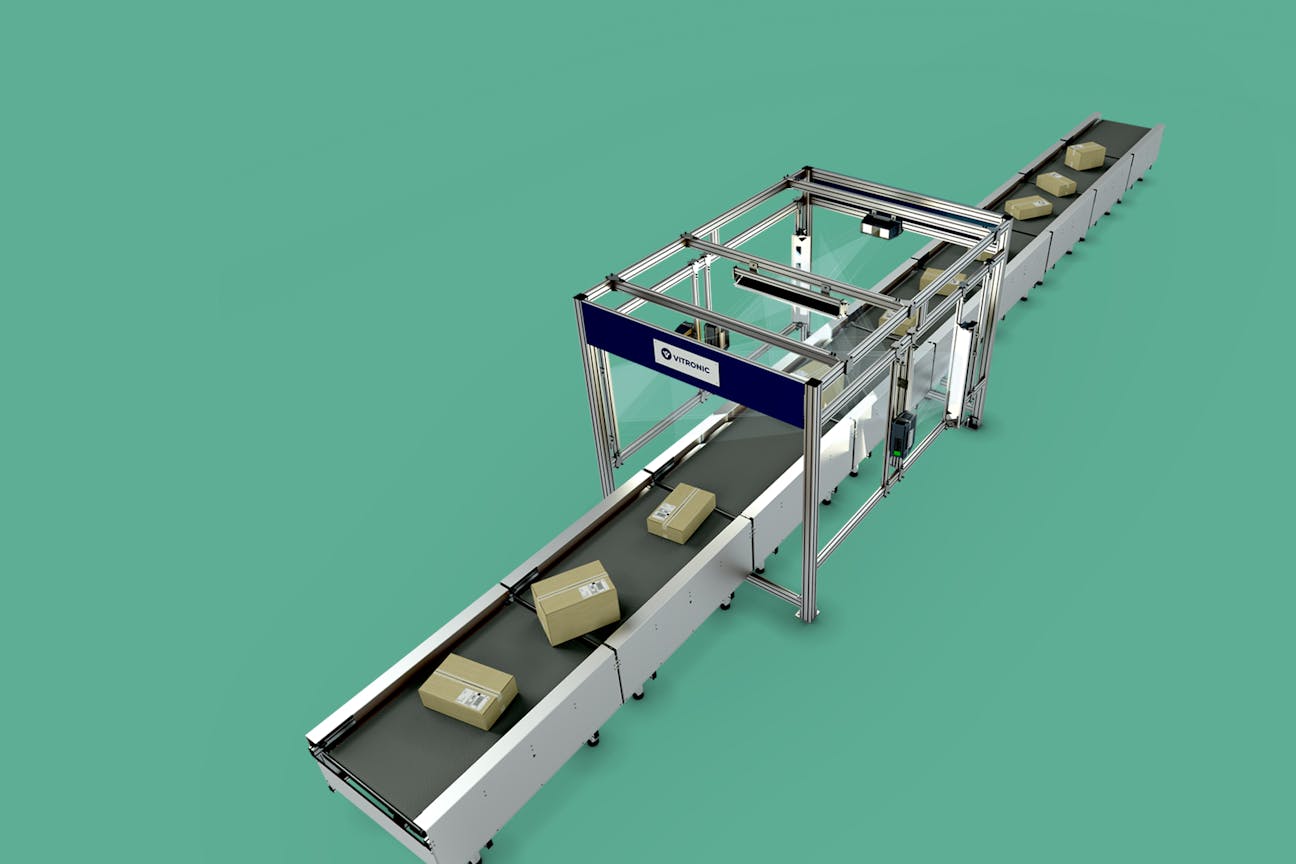

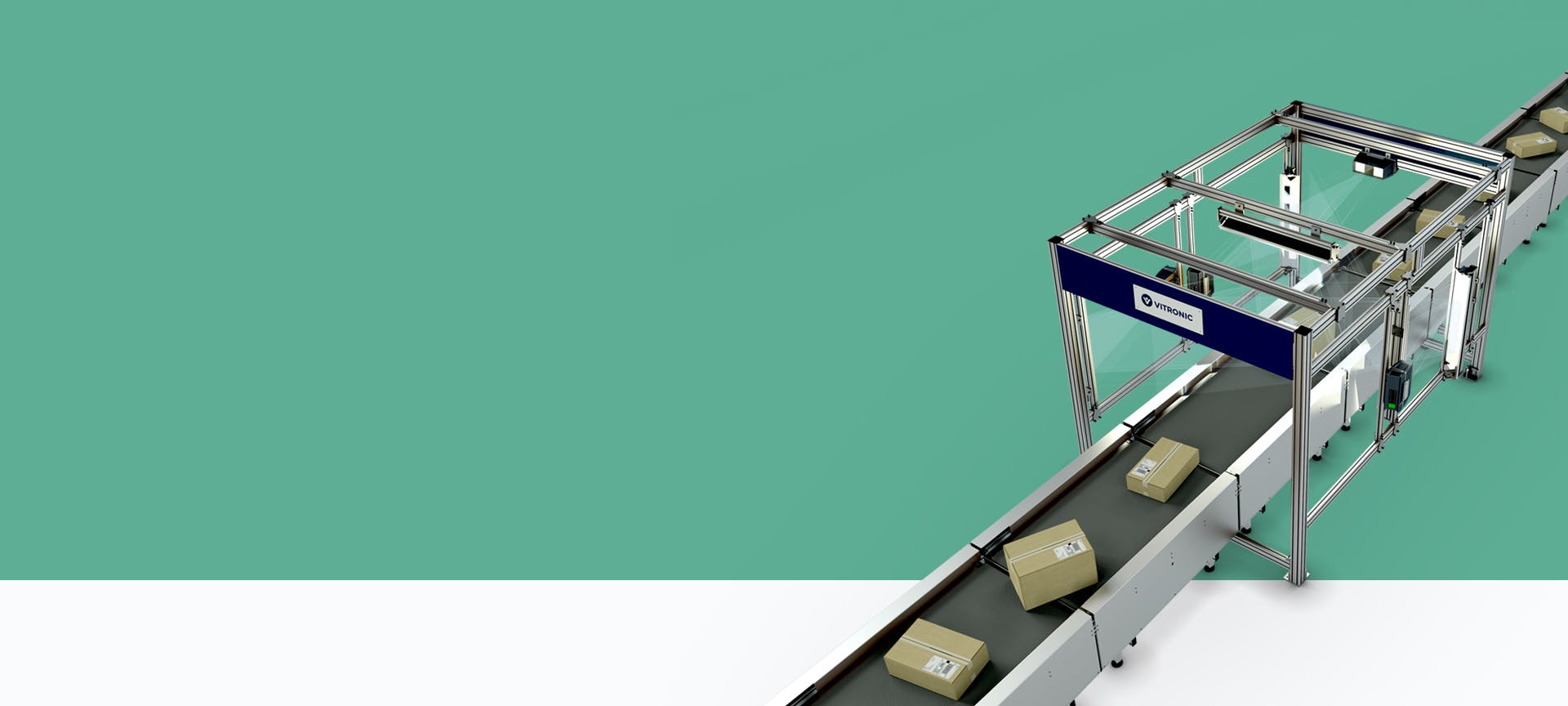

Data Capture and Documentation in Outgoing Goods Areas

Order Picking and Outgoing Goods Inspection

For Taking away and Passing on

Brochure

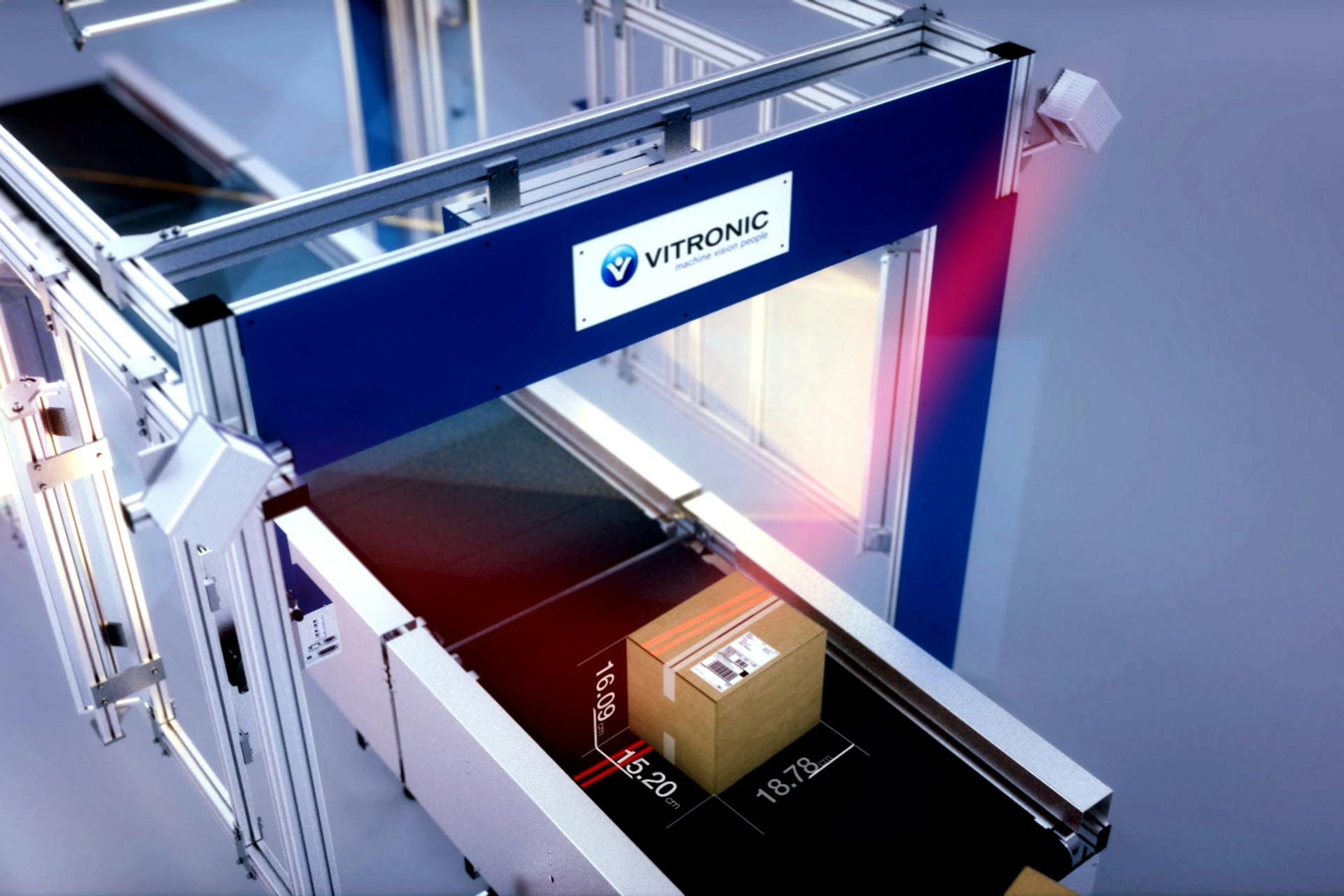

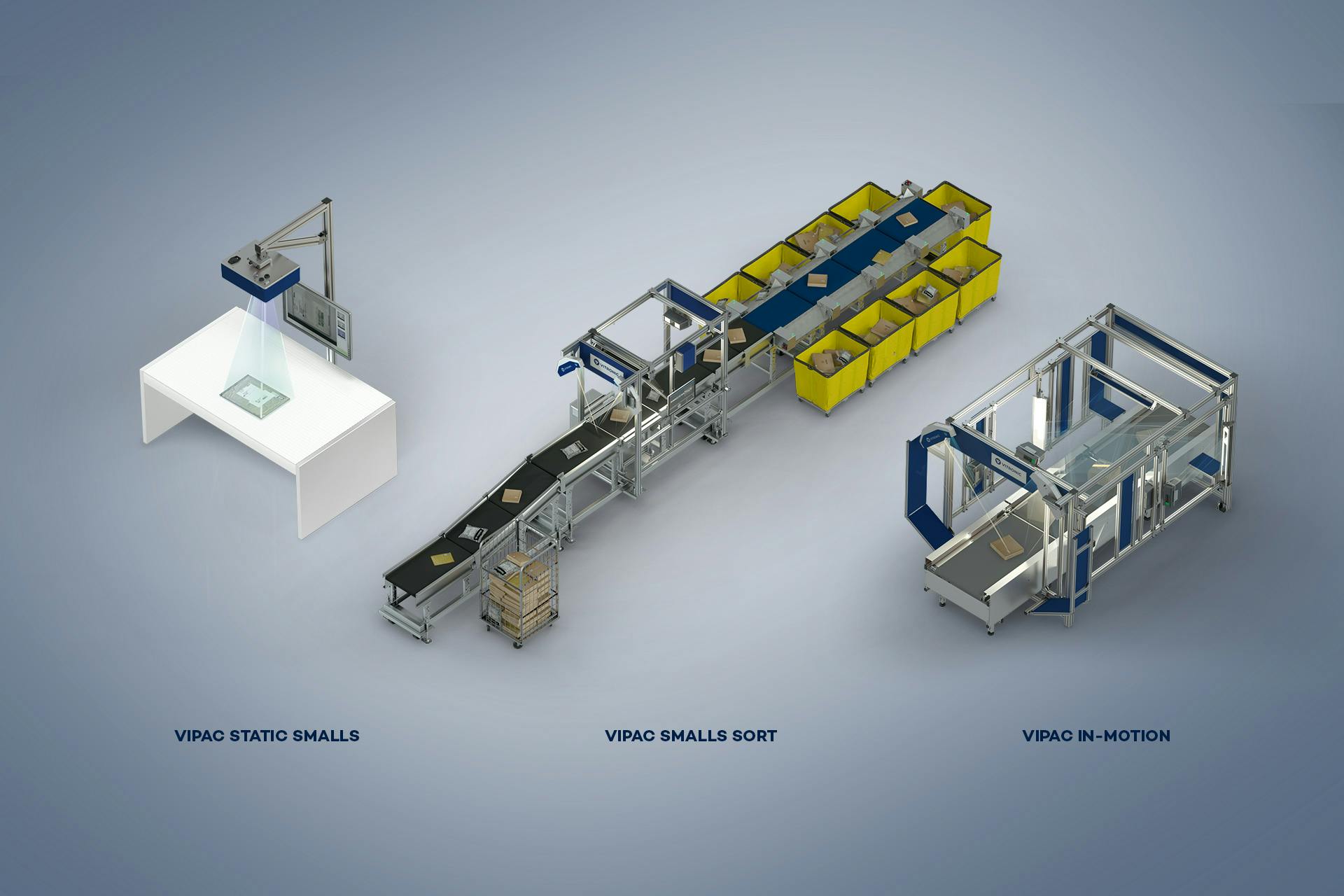

Auto-ID systems for more efficient logistics

Brochure

Reading systems and volume measurement