Menü

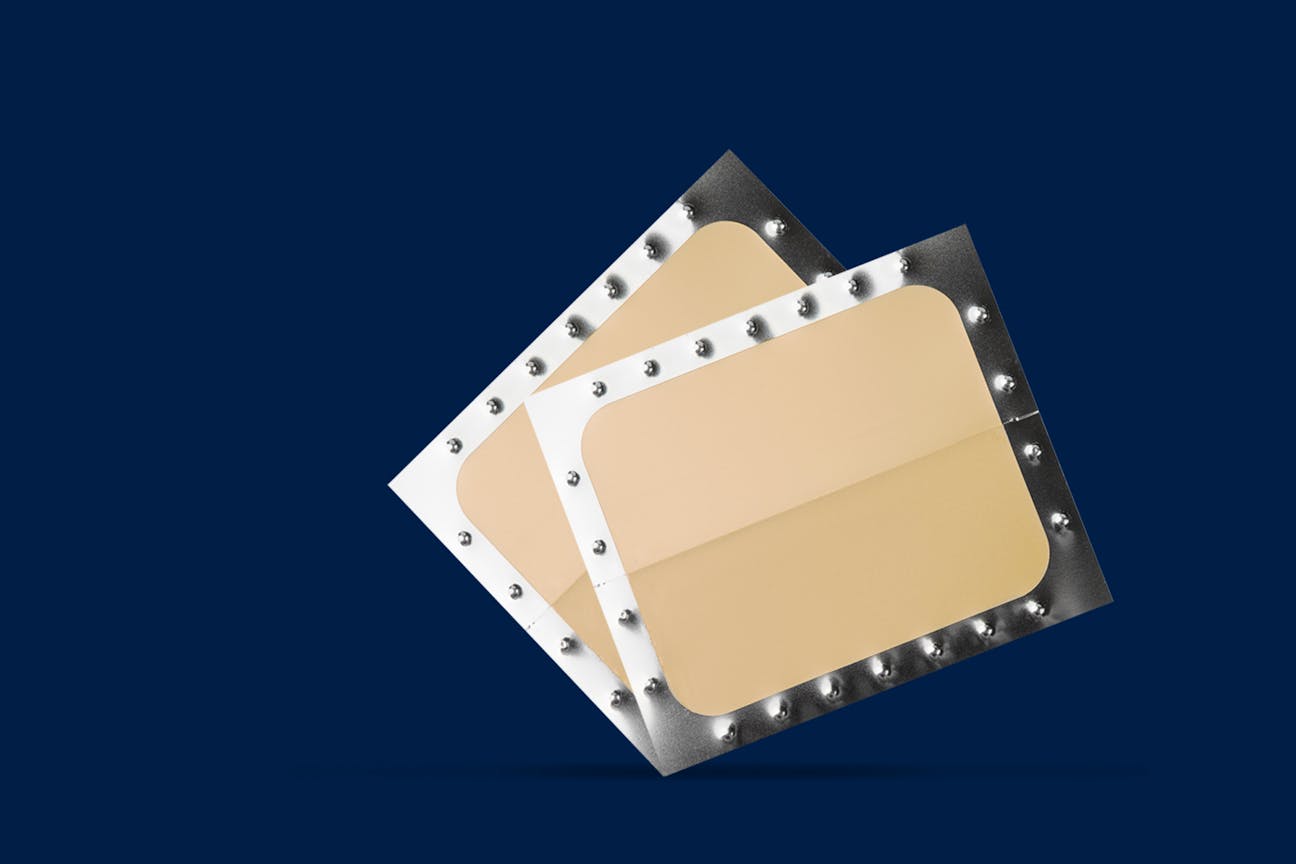

Transdermal Patch Inspection Convenient Therapy That's Safe Too!

Inspect Transdermal Patches Safely and Efficiently

Transdermal Patch Inspection

For Taking Away and Passing On

カタログ

VINSPEC HEALTHCARE—Inline Pharmaceutical/Medical Device Inspection

カタログ

VINSPEC HEALTHCARE—for Transdermal Therapeutic Systems