Fair Battery Show Novi 2022

| lang-id:label-datetime | 2022-09-13 – 2022-09-15 |

|---|---|

| Ort | Novi, MichiganShowplace, Novi, MI |

| Halle/Stand | To be added |

Expectations of future electromobility solutions are rapidly increasing. Even more powerful batteries need to be developed. The goals are clear – a more compact design, more power, a greater operating range, and a longer life expectancy. With leading optical inspection systems, VITRONIC is the partner you can rely on to get tomorrow’s electromobility solutions up and running today.

Visit us:

Our booth number will be announced soon

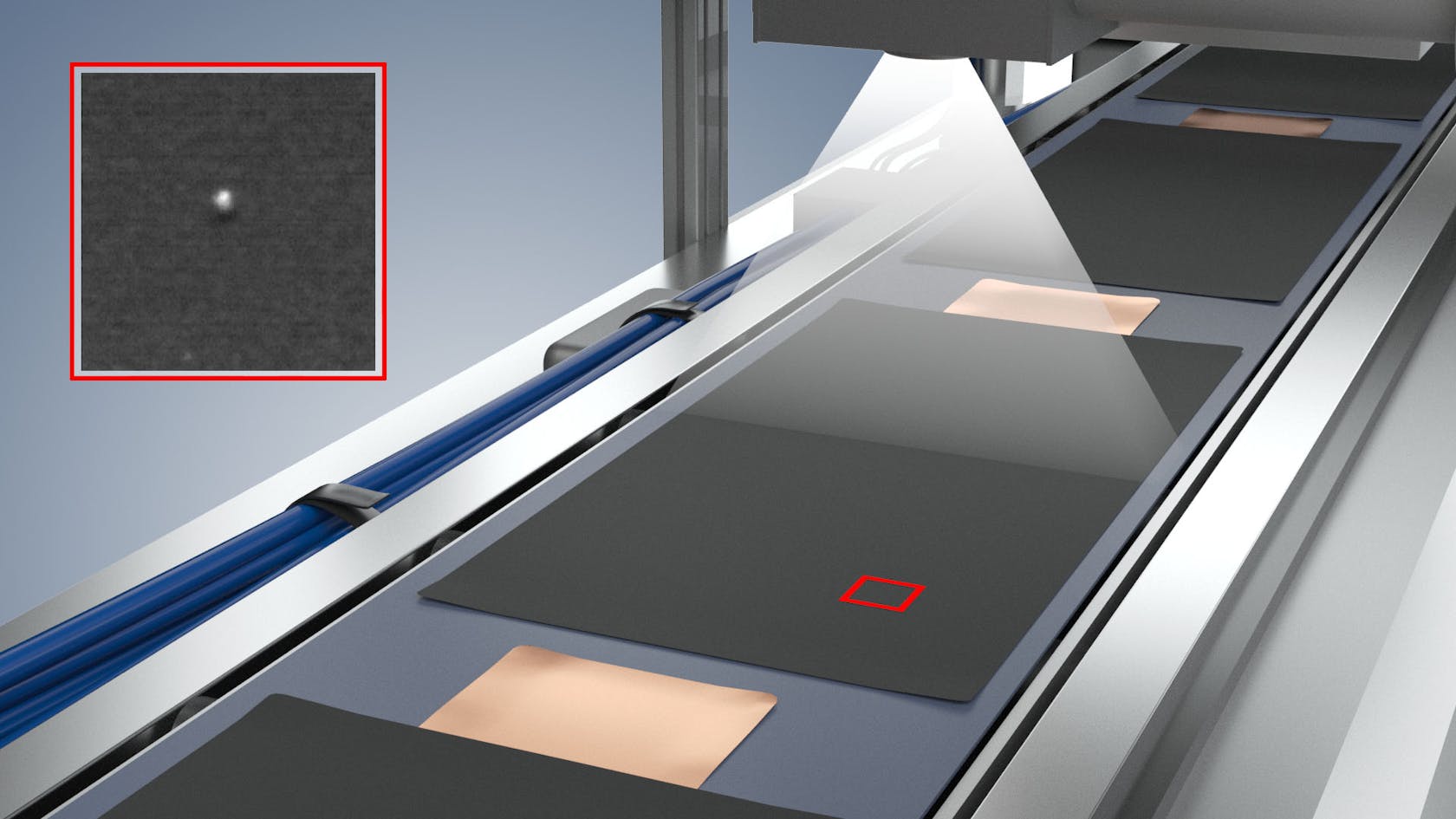

During the production of stacked electrode-separator composites, the highest cleanliness requirements apply.

VINSPEC inspection solutions use fast and high-resolution sensor technology to detect protruding particles and defects on battery electrodes from 10 µm at production speed.

Weld seams are an important element in ensuring the safety of all passengers in a vehicle. Our automated weld seam inspection ensures that the high requirements for battery production are met.

The early detection of defects is central for the optimization of production processes. In battery module production, optical machine vision systems check the completeness of the module and the orientation of the individual battery cells and tags.