Solutions Weld Seam Inspection Automated Inspection of Weld Seams

Cutting-Edge Technology for Flawless Weld Seams: Wherever it comes to safety-critical weld seams and high quality and performance requirements, VIRO WSI is a key component in automated manufacturing. Because thanks to VIRO WSI, only flawlessly welded components make it to the next step in the production process.

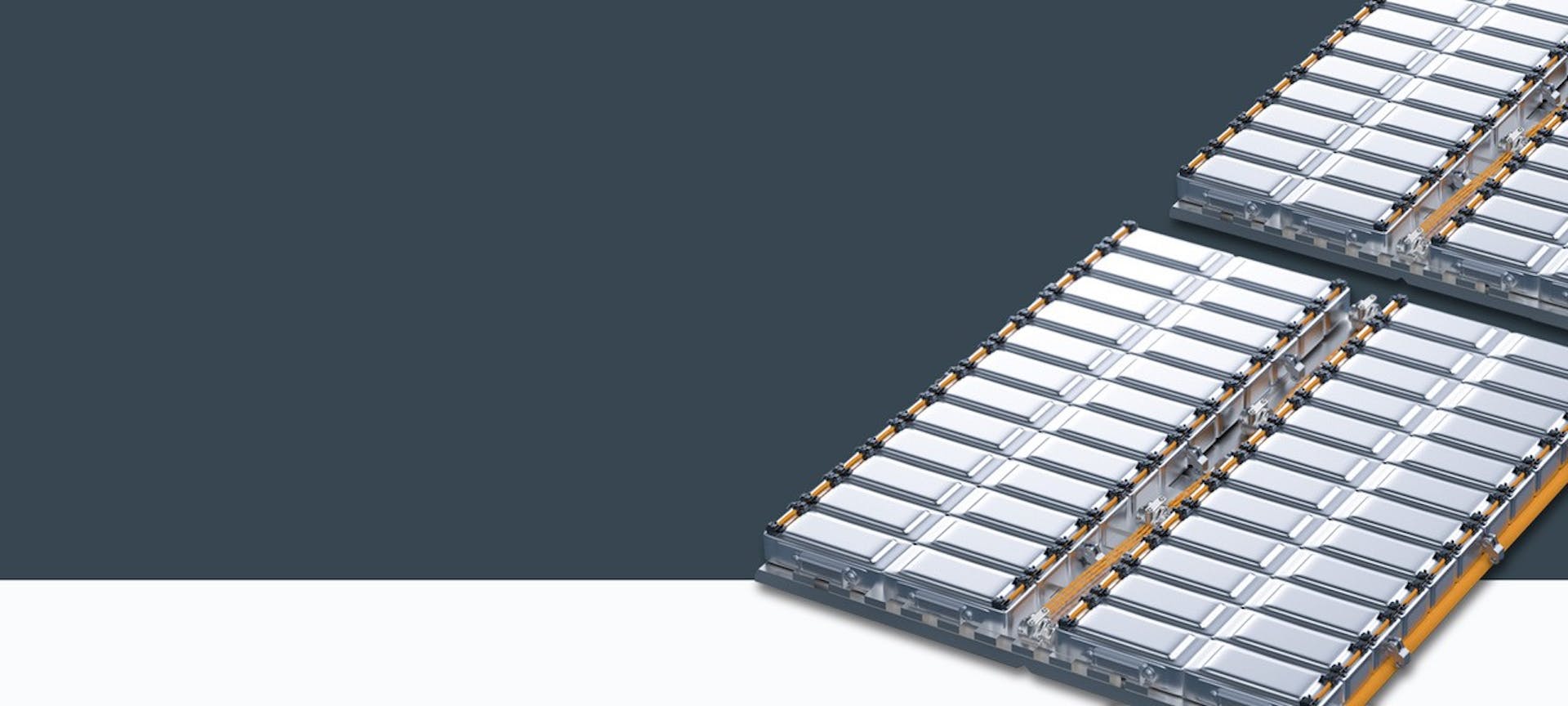

The international automotive and component supplier industry has been using VIRO WSI successfully since 1995. It is used for automatically welded components in powertrains or car bodies, as well as battery production for e-mobility.

4 Applications in

VIRO WSI: Automated Weld Seam Inspection

The VIRO WSI optical inspection system is a state-of-the-art automated solution for serial production that performs a thorough weld inspection after the welding process is complete. This system, designed specifically for weld seam inspection by VITRONIC, employs laser-based technology for a non-destructive testing (NDT) approach. Its capabilities include a visual inspection of all seam types, independent of the welding methods used, pinpointing welding defects with precision down to 0.1 millimeter.

In its arsenal, VIRO WSI integrates various welding inspection tools and techniques to evaluate welded joints, setting industry standards for both welding inspection and automated brazed seam inspection. This innovative system can detect a variety of flaws such as incorrect weld size, spacing issues, and surface cracks—common issues that welding inspectors are on the lookout for.

Quality control is paramount, and VIRO WSI's inspection system excels at it, reliably functioning even on complex components with hard-to-access areas or on surfaces that are typically challenging due to their reflective nature. It uses a sensor paired with a powerful computer processing unit and sophisticated software, which has been refined over numerous field tests.

VIRO WSI's versatility extends across industries, from inspecting weld seams on automotive parts to ensuring the integrity of welds in the steel construction industry, where welding defects could compromise structural integrity. In the engineering sector, it ensures fillet welds and other seams are free from internal flaws.

Beyond welding inspection, VIRO WSI proves its utility in examining adhesive bonds, crucial for industries shifting from traditional welding processes to modern bonding techniques. Here, the system ensures that sealing beads are free from imperfections that could affect the bond's quality.

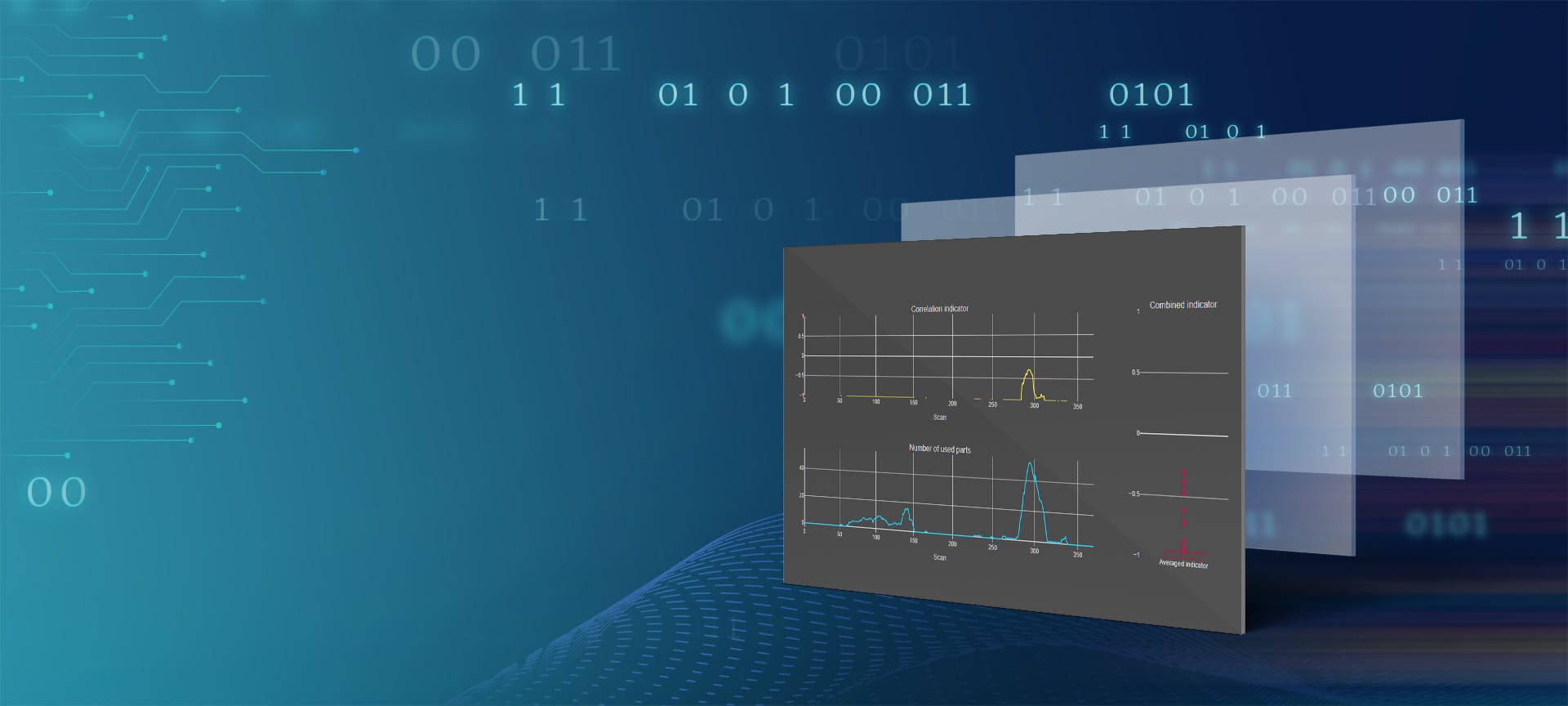

Reworking is streamlined with VIRO WSI, as it highlights defective components and seams, guiding manual reworking with interactive visualization stations. It's equipped with a unique software algorithm that supports both manual and automated reworking processes.

In the drive to improve product quality, VIRO WSI stands out for its inline inspection capability, allowing immediate intervention in the welding process to minimize weld failures. This proactive approach not only enhances the product quality but also reduces downtime and waste.

All inspection results are meticulously documented in a database, ensuring traceability and forming a solid foundation for process analysis and optimization. By integrating NDT methods like magnetic particle testing, ultrasonic testing, and liquid penetrant inspection, the VIRO WSI system facilitates a comprehensive examination of welds, essential for companies aiming to maintain a competitive edge in quality assurance.