Coating Inspection Balancing Product Quality and Cost Efficiency

Precise, Reliable Coating Inspection for the Best Results

Coating Inspection

Automatic Optical Inspection Detects All Process Deviations at an Early Stage

A stable production process is vital to solar-cell coating. Even with this in place, quality-relevant deviations can still occur. With AOI, these can be detected as a trend reliably and early on—helping you avoid machine downtime.

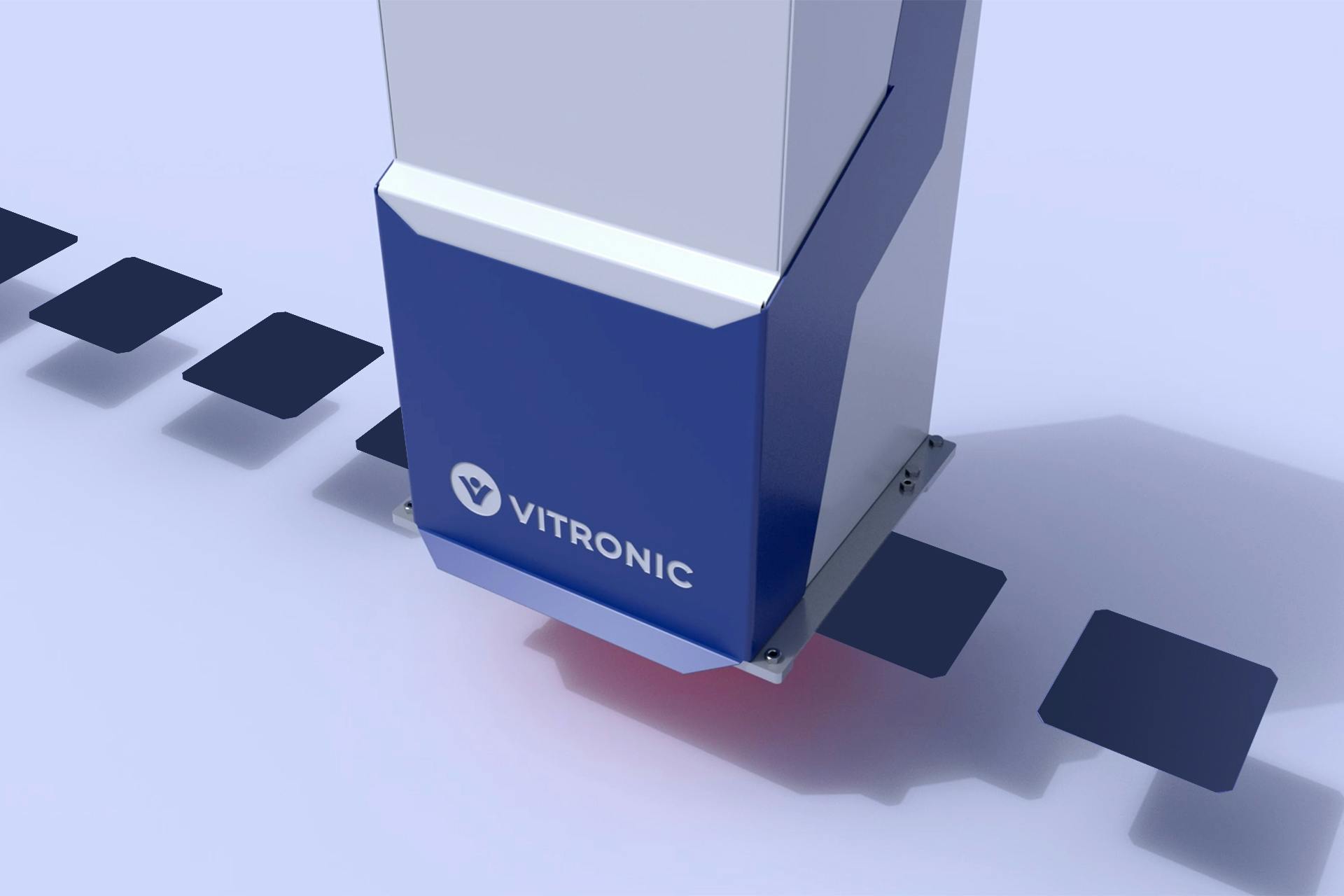

The solution from VITRONIC detects color deviations and local defects at maximum process speeds and enables the highest possible yield to be achieved in a cost-efficient way.

Consistently High Quality Thanks to Automatic Inspection

A coating inspection for solar cells seeks to ensure a continuously high percentage of top-quality cells with a homogeneous texture, color, and coating thickness. The best inspection results and quality assurance are achieved with AOI from VITRONIC. With this solution, you benefit from reliable, early detection of global and local deviations. In the event of a malfunction, you can adjust the process parameters to increase your output.

Benefit From Effective Trend Analysis and Predictive Maintenance

Machine downtime is detrimental to production. But it can be effectively avoided with a coating inspection from VITRONIC.

Manual inspections are less reliable and inadequate in terms of quality. AOI enables early detection of malfunctions and process changes, as well as low supply quality. Fast defect detection immediately after a process step prevents low-quality products from making their way to further processing. Relevant changes occurring in isolation or as a trend are reliably detected. So you can optimize your processes in a sustainable way.

- >7.500wafers/h

Look to the Future

Robust, Precise, and Reproducible Across All Lines.

VINSPEC SOLAR for Coating Inspection is an innovative, future-proof inspection system with a modular structure that can be easily adapted to meet individual requirements. The solutions, based on line or matrix technology, use high-end hardware and are easy to install and operate.

Our new software is based on powerful algorithms. The coating inspection offers process-relevant functions, such as yield control, heat maps, statistics, and trend analysis. A seamless concept thanks to 35 years of experience in image processing.

In Brief

Thorsten Daus

Product Manager Healthcare | Photovoltaics- Telefon

- +49 151 689 622 86

- thorsten.daus@vitronic.com

Follow me

VINSPEC SOLAR—Reliable and Cost-Efficient Coating Inspection

In Brief

- Optimal Yield

- Early error detection

- Cost-efficient processes