The courier, express, and package service provider (CEP) market continues to show strong growth in Germany. After the record level of 3 billion deliveries was reached in 2016, the industry showed renewed growth up to 3.5 billion deliveries in 2018. That’s more than double the number of deliveries clocked up in the year 2000. On average, 12 million deliveries were made to up to 7 million recipients each working day—that’s quite a logistical feat. Four out of every five consignments are packages, and most of these go to final consumers.

This fact reveals that CEP services are indispensable to the booming e-commerce economy. It's hardly surprising, then, that processes in depots and distribution centers are required to run as efficiently and economically as possible.

Thinking in terms of digital processes

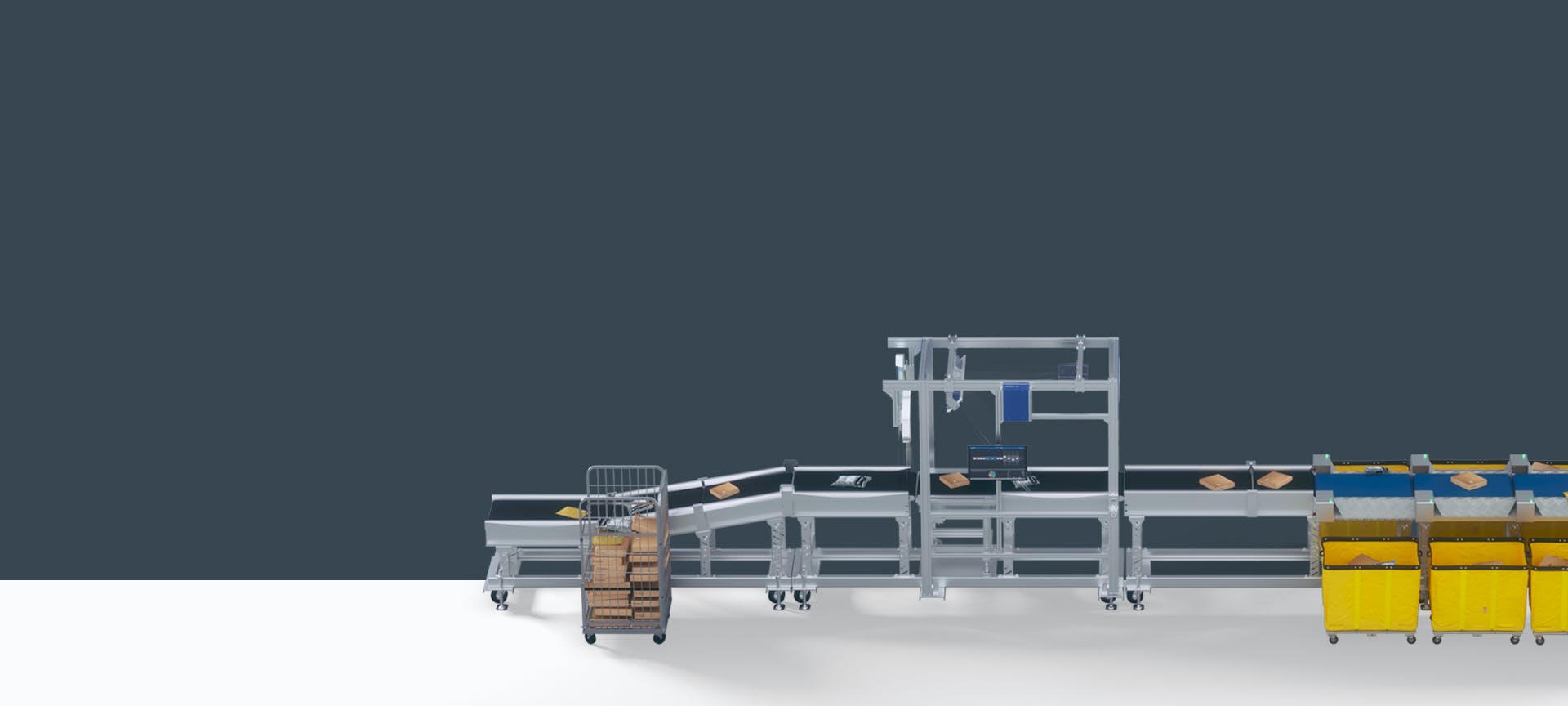

And for businesses to successfully tackle this challenge, they need automated solutions. Automation is necessary to compete and ensure that growth is steady and sustainable. That’s why the goal must be to achieve digitization and interconnectivity along the entire supply chain.

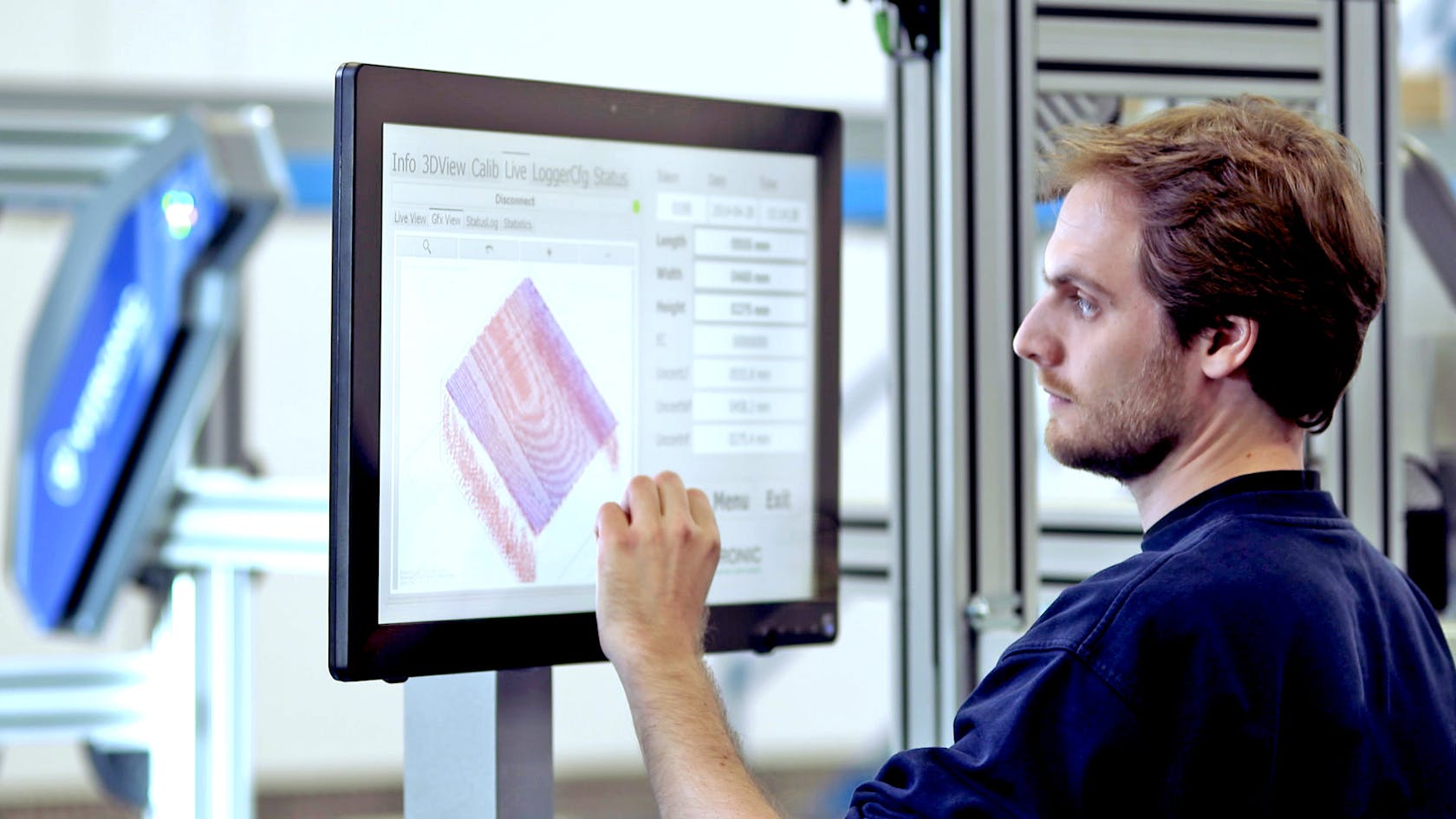

Fast, reliable and intelligent data capture of deliveries and packages is essential. In the CEP sector in particular, fully automated and camera-based identification systems, known as Auto-ID solutions, are key. And more and more, these solutions must be able to process and manage ever-increasing volumes of data.

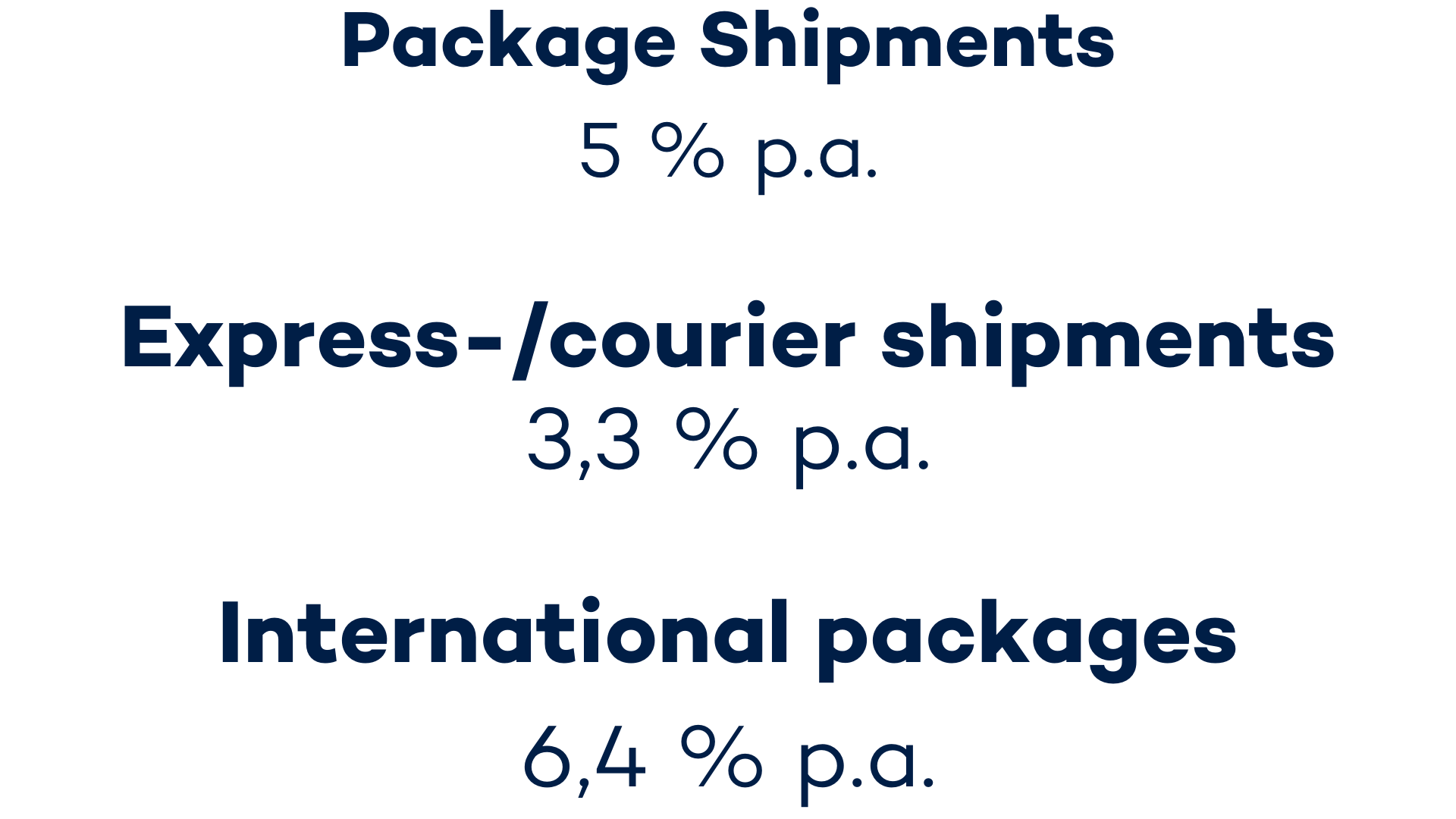

More B2C, more non-EU

Even if slightly lower growth than the rate recorded last year is expected in the medium term up to 2023, the trend of above-average growth in packages delivered will remain steady for all market segments. The continued growth in deliveries by a total of 4.7% is largely accounted for by increased online sales and more international deliveries.

Global integration

An important topic is global integration, in particular for international logistics companies with process chains that span multiple locations. Software structures must be able to replicate this, analyze the data from all locations and then link it together. Auto-ID systems don't just ensure efficient and seamless data capture, but also store all information with compressed images in a global archiving system. Customers can run targeted evaluations, resulting in greater transparency.

A smart supply chain

A smart supply chain is only possible by bundling all information and linking it to its related processes.

The data is transferred by intelligent systems to:

- the conveyor system's control unit,

- connected inventory control systems,

- warehouse management software,

- or higher-level ERP and SAP solutions.

All volume and weight data is captured in a way that is certified and made available for automatic invoicing. This data also supports precise planning of shipments. Better capacity utilization means lower costs, and thus more efficient logistics.

Data security and a robust, transparent IT infrastructure are also of growing importance. Seamless traceability along the entire supply chain is particularly critical for international logistics service providers. All information can be archived locally and centrally, and can be accessed at any time through a web-based interface. The systems are certified and use redundant servers because the only way to prevent possible breakdowns in the logistics chain is to store data twice.

Data is this century’s gold

Leading package and express service providers use VITRONIC solutions to optimize their processes and drive digitization. This is where Auto-ID solutions and DWS systems provide the data for the digitization of the supply chain. Automated systems make it possible for businesses to maintain a complete and transparent pool of data. Transparent data constitutes a basis for more efficient processes and for new products that are tailored to meet customers' needs, such as same-day delivery or shipment tracking in real time.

Summary

In brief

- The CEP sector hits a new record high in 2018: 3.52 billion packages delivered

- Forecast: all market segments will grow up to 2023

- Automation and digitization are essential in package logistics

CEP branch: Auto-ID solutions and DWS systems provide the data for digitizing the supply chain.

You can edit this slice directly in your code editor.