Surface Inspection for PowertrainsQuality Assurance for All Drives

Optical Inspection of Visible, Sealing and Functional Surfaces

Surface Inspection for Powertrains

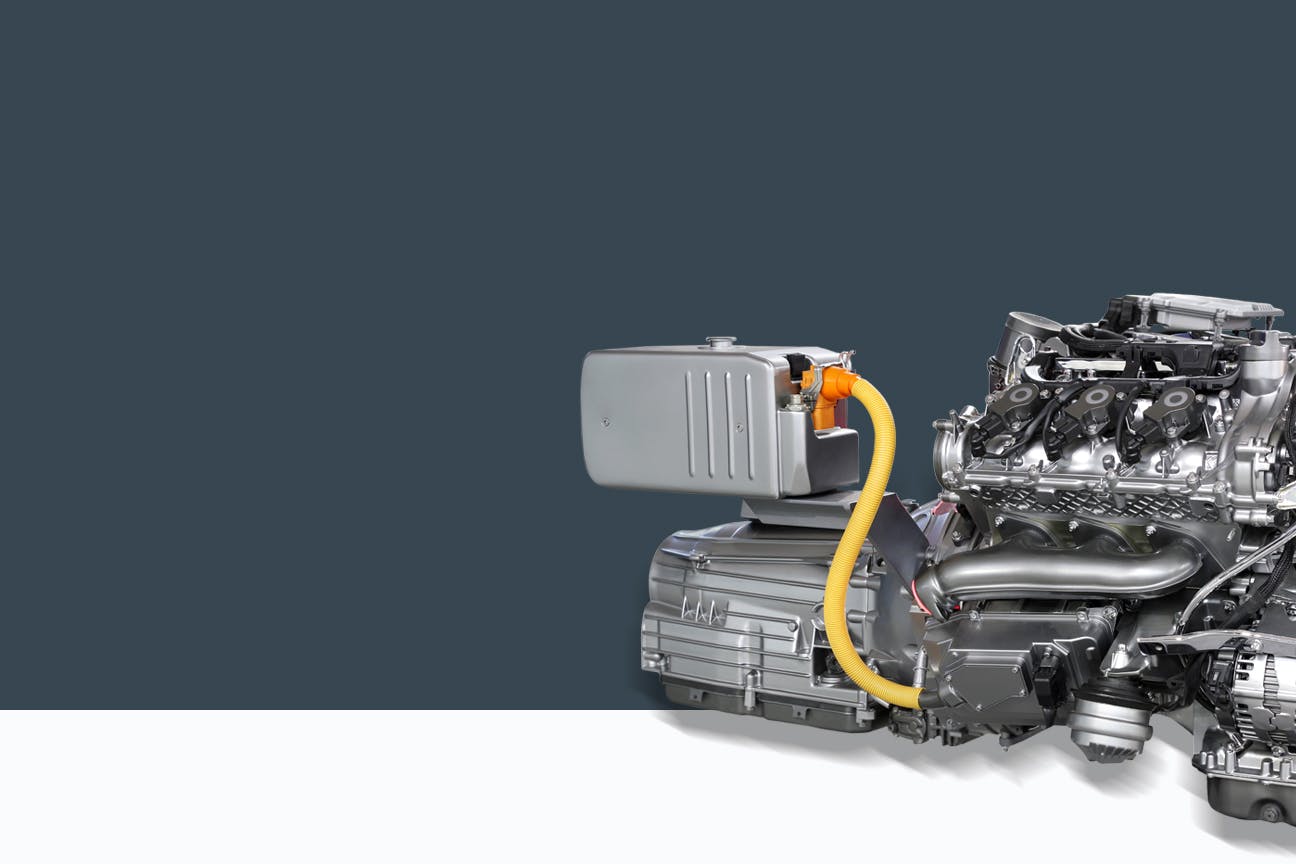

The energy transition in traffic technology is within reach and there is a growing demand for alternative, energy-saving, low-emission drive technologies. This also demands a radical rethink on the part of the automotive industry. Short development cycles, innovative manufacturing and assembly processes and new production lines mean constant challenges.

But how can complex drive components be manufactured economically? By using efficient manufacturing processes and powerful quality inspection. Read on to find out how you can rely on our systems and our expertise, even for the most challenging inspection tasks.

For All Drive Technologies

Regardless of which drive technology you manufacture, production efficiency is only possible if the smallest errors can be reliably detected during the manufacturing process.

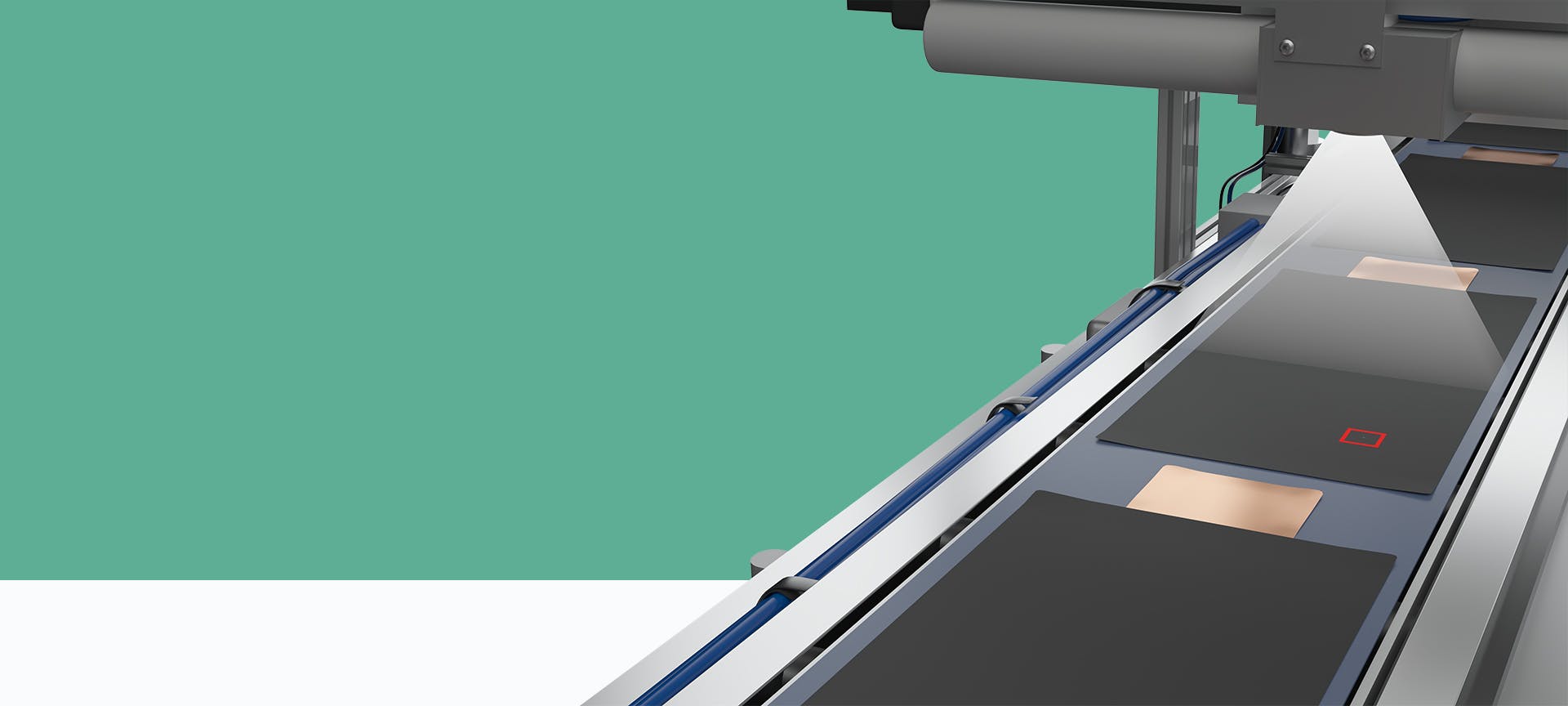

VINSPEC inspection systems offer seamless quality assurance for the entire powertrain. They inspect powertrain components for defects such as cavities, pores and excess material, or processing errors such as scratches and dents—with micrometer precision.

It doesn't matter which drive technology, component or deviation you want to inspect—our engineers will find the right solution for your inspection task.

Which components does VINSPEC inspect?

Whether a modular solution or a turnkey solution with a complete inspection cell is right for your production line, the inspection is always inline. As a result, flaws on the visible, sealing and functional surfaces are reliably identified during production—preventing further processing of defective parts.

As a result, only flawless, powerful drive components will leave your production lines. This lets you cut costs and ensure high quality.

- 24.7max. availability

- 100%process-oriented

Automation Sees Everything — Always!

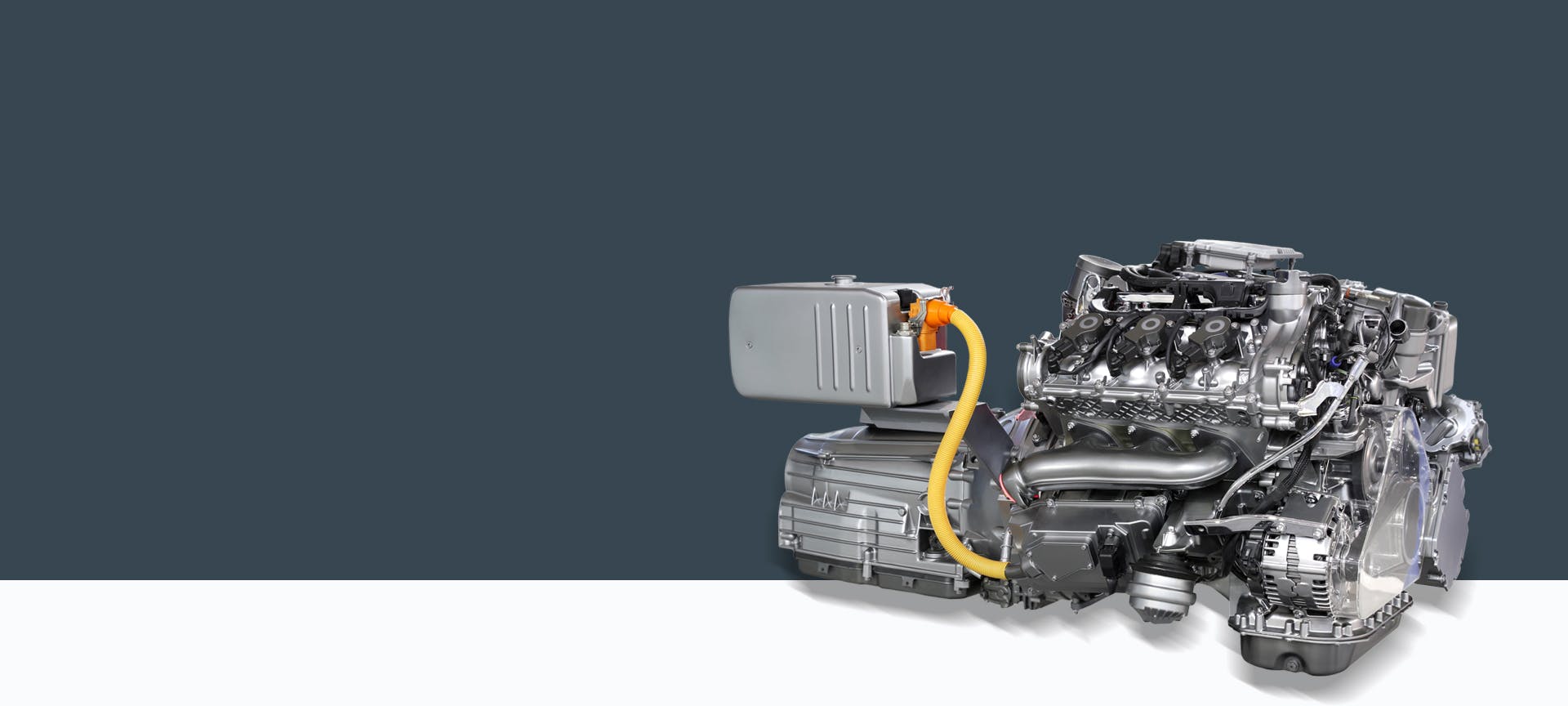

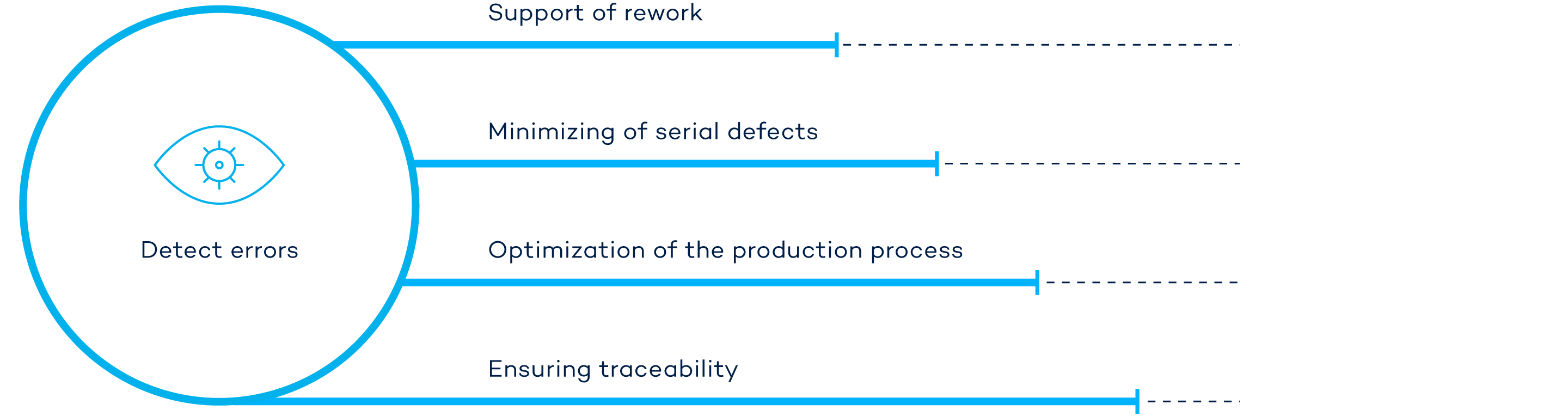

Optimize Processes

Every manufacturing step has its challenges — and the potential for optimization. The VINSPEC inspection system documents and saves all inspection results and even takes account of information from other sources. From this cumulative data, you can implement direct and lasting process optimizations. And, if reworking is an option, the system can support you with that too.

This will enable you to achieve your goal of reducing costs at each stage of the value chain and producing increasingly high-quality powertrain components.

We are Partners for the Automotive Industry

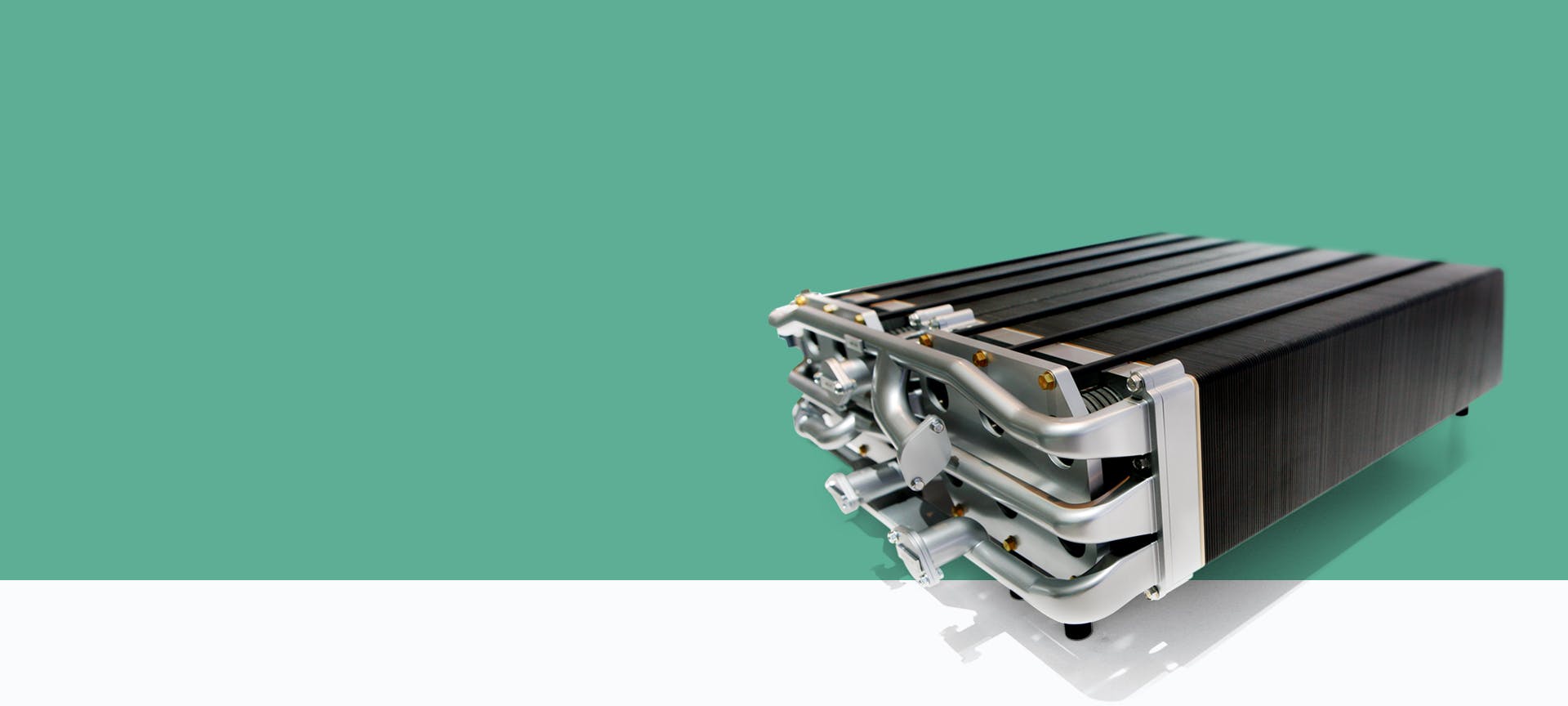

Since 1995, OEMs and automotive parts suppliers have been successfully using our powerful, scalable inspection systems in production — for example, for quality assurance of surfaces, geometry and weld seams on car bodies, powertrains and in battery and fuel-cell manufacturing.

Our customers benefit from our expertise, our project experience—and our tireless dedication! We always achieve the best solutions by collaborating with our customers as partners.

Technology Shift

More complex drive technology also means more complex quality requirements. But these requirements must be met if goals such as great range, longer component life, energy-saving and reduced emissions are to be achieved. For enhanced climate protection for us and for the generations to come.