Smart LogisticsThe key to staying competitive in Logistics

How automation is making e-commerce faster, safer, more traceable, and more cost-effective.

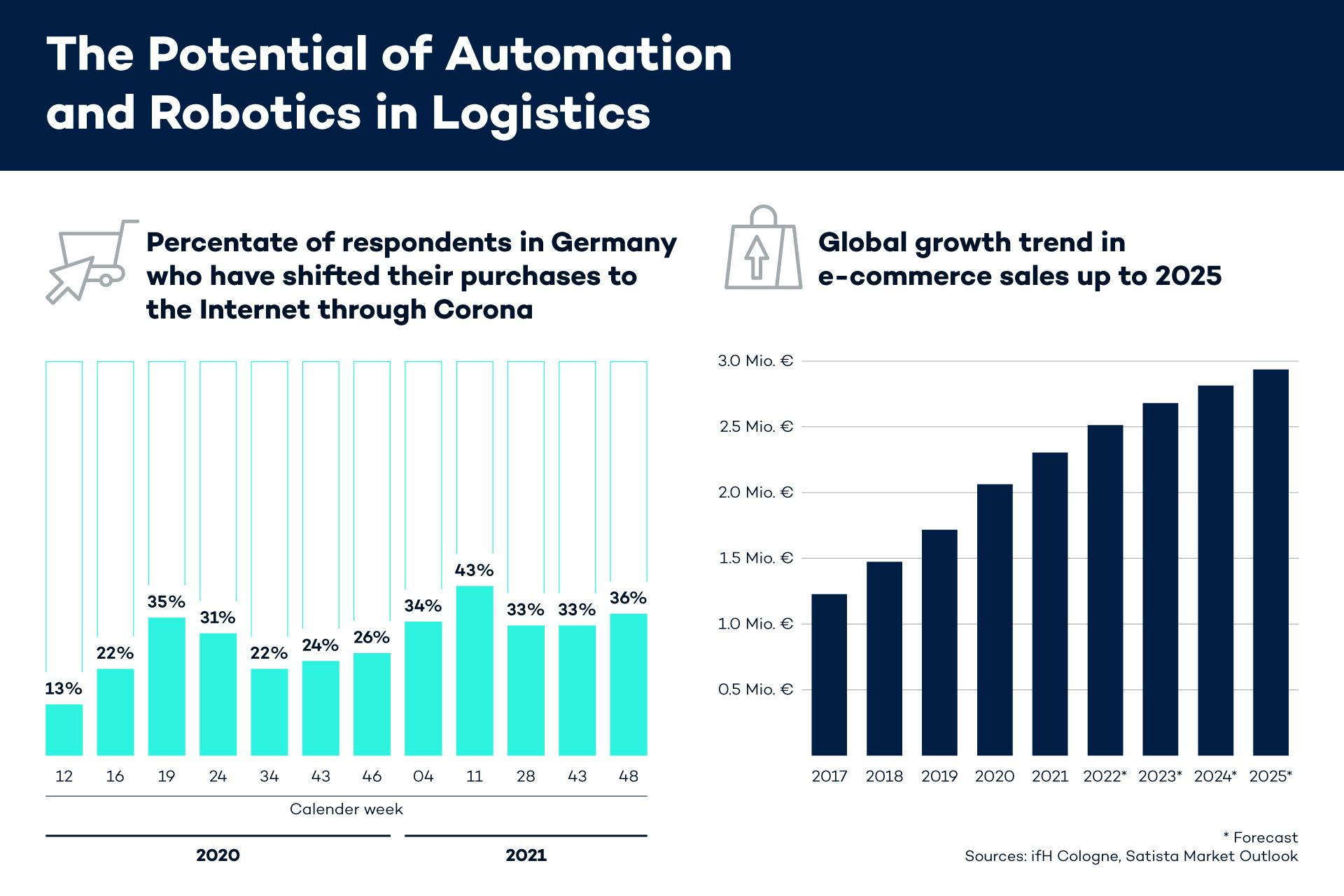

And this trend is ongoing. International CEP providers are still facing this pressure. It became the “new normal,” just like Working-From-Home or Telemedicine. In the U.S. and worldwide, the peak e-commerce shopping does not go from Thanksgiving / Black Friday to Christmas—we are currently seeing peak level volumes continuing throughout the year. The pandemic has definitely spearheaded a growing number of shipments.

Customer expectations are unparalleled in the e-commerce sector

It’s no secret that the pandemic has presented several supply chain issues – especially in the e-commerce sector, where customers expect goods to be delivered faster and more accurately than ever before while the labor market is struggling to keep up with the growing demand in the logistics sector. So how can retailers and CEP companies remain competitive? What, exactly, must they do to give consumers the options—and the service—they expect?

Companies like Amazon have created an atmosphere of instant gratification. There is zero tolerance for being late and little room for error. Say, for instance, you visit an online clothing store and find the brand is missing three colors, two sizes, and several styles. Rather than relying on time-consuming human processes, the retailer might turn to automation. They might connect multiple warehouses using AI - navigating product availability issues by giving consumers access to all the brand’s inventory in different locations. Why is this important?

Track and trace capabilities present further complications. Because consumers can now monitor where their orders are in the logistics process, there’s unprecedented visibility. This visibility requires more accountability from retailers and delivery companies. However, errors happen during manual processes. So reliable automation solutions are needed to significantly increase accuracy and help get the packages delivered to the correct destination on time.

Current demands go beyond human resources & capabilities

Automation is also a key to solving two other major labor-related challenges that logistic companies face:

- Lack of skilled workers

- The growing complexity of tasks.

Modern automation technology can help the postal and parcel companies keep up with the business volume they deal with, even if it can sometimes be difficult to find the resources. Several package delivery and warehouse operators are struggling to staff their manual processes. This is often due to the increased competition resulting from other higher-paying, more “appealing” jobs. Many logistics companies also have an aging workforce that will need to be replaced in the next few years. These trends, particularly the labor challenges that package delivery companies face, reinforce the need to invest in automation.

Moreover, many of the increasingly complex tasks can’t be executed by humans anymore. For instance, automation can improve worker safety and ergonomics. Many tasks within the package delivery process can be unsafe for humans, e.g., contact with hazardous materials while loading and unloading. On the other hand, the ability to accurately and automatically identify and process data like codes, characters, weights, dimensions, package type, and material risk is essential for key applications like data capture, sortation, inspection, revenue recovery, returns, freight optimization and the ability to track the package throughout its journey from shipper to the customer. Intelligent automation solutions ensure they gather petabytes of correct information – something humans can’t process.

To tackle the growing number of shipments, a unique blend of robotics, material handling systems, and automatic identification technology that sorts packages for dispatch to shipping centers is needed to manage the growing number of e-commerce packages that enter logistics companies’ systems each day.

Our customers are especially interested in systems, which provide data for seamless process flow and the tracking of their goods. The data is needed to verify shipping cost on both ends, for the customer and CEP provider.

Therefore, now more than ever, we are seeing a spike in demand for automated package sortation. According to the Report “Courier, Express and Parcel (CEP) Market" (see footnote), the growing e-commerce sector, along with growing cross-border trade, is one of the main driving forces behind the growth of the CEP market. The market experts expect a growth in CAGR of 5.2 percent during 2021-2026. And this increase in shipments will also have a direct impact on the providers of global Automation Solutions, especially sortation systems, which are projected to reach the ~US$ 2 billion mark by 2027.

Reducing the cost by up to 40 percent while supporting growth

Automation supports the expected growth in e-commerce. When e-commerce package volumes surged during the pandemic, existing processes and equipment, as mentioned above, struggled to keep up. These constraints highlight the need to invest in automation solutions that can be easily scaled to meet increasing demands and quickly adapted to manage volume increases during peak periods (i.e., over the holidays).

An ongoing Roland Berger study also reveals that automation will help reduce logistics costs by 20 to 40 percent and increase productivity by 25 to 70 percent by 2025.

Summary

IN BRIEF

- The advantages of using automation in logistics go far beyond reducing the need for employees.

- Automation is the key to lowering logistics costs.

- Intelligent automation and robotics pave the way for higher throughput.

- Automation ensures flexibility and scalability.

You can edit this slice directly in your code editor.