New Heights of Performance with 13 Cameras

Automated visual inspection of BFS containers

In the medical device industry, blow-fill-seal (BFS) containers fall into the category of difficult to inspect parenterals. Accordingly, an optimized inspection offers the potential of significant potential efficiency gains.

The starting point

If a BFS container is defective, this could have serious consequences for the health of patients. A leading global pharmaceutical and medical supplies company was looking to set up a new large production line for BFS containers with a filling volume of 100 ml.

As VITRONIC has the expertise required, the company was tasked with designing and implementing an inspection solution for the new production line. VITRONIC has been developing systems of this kind for clients for 25 years and implemented the first comprehensive visual inspection solution for BFS containers for this company in 2014.

Implementation

A central aspect of the solution implemented is that the inspection is “static”. The product passes through the machine, without needing to be turned, tilted, or presented in any other form that is not essential from a manufacturing perspective.

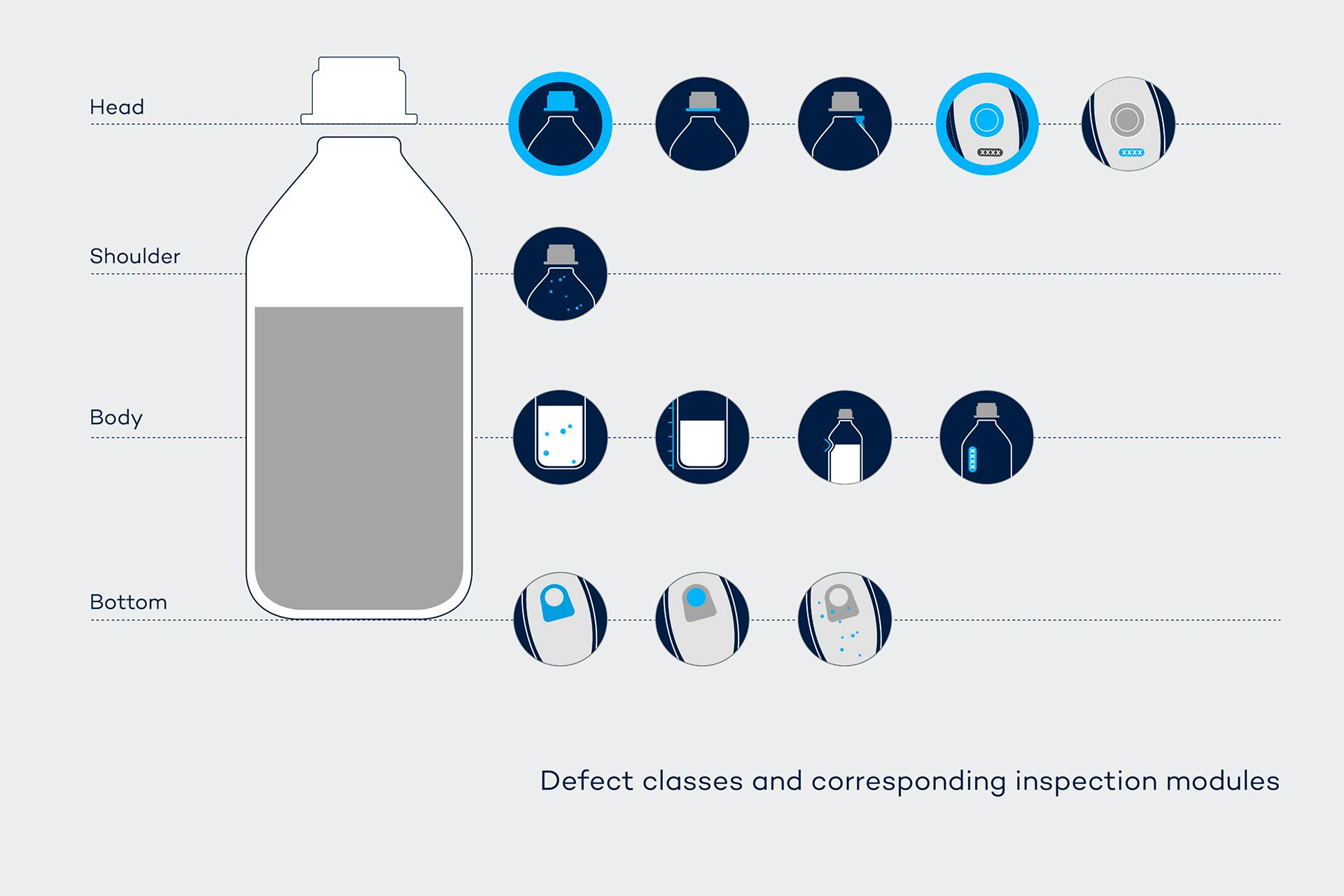

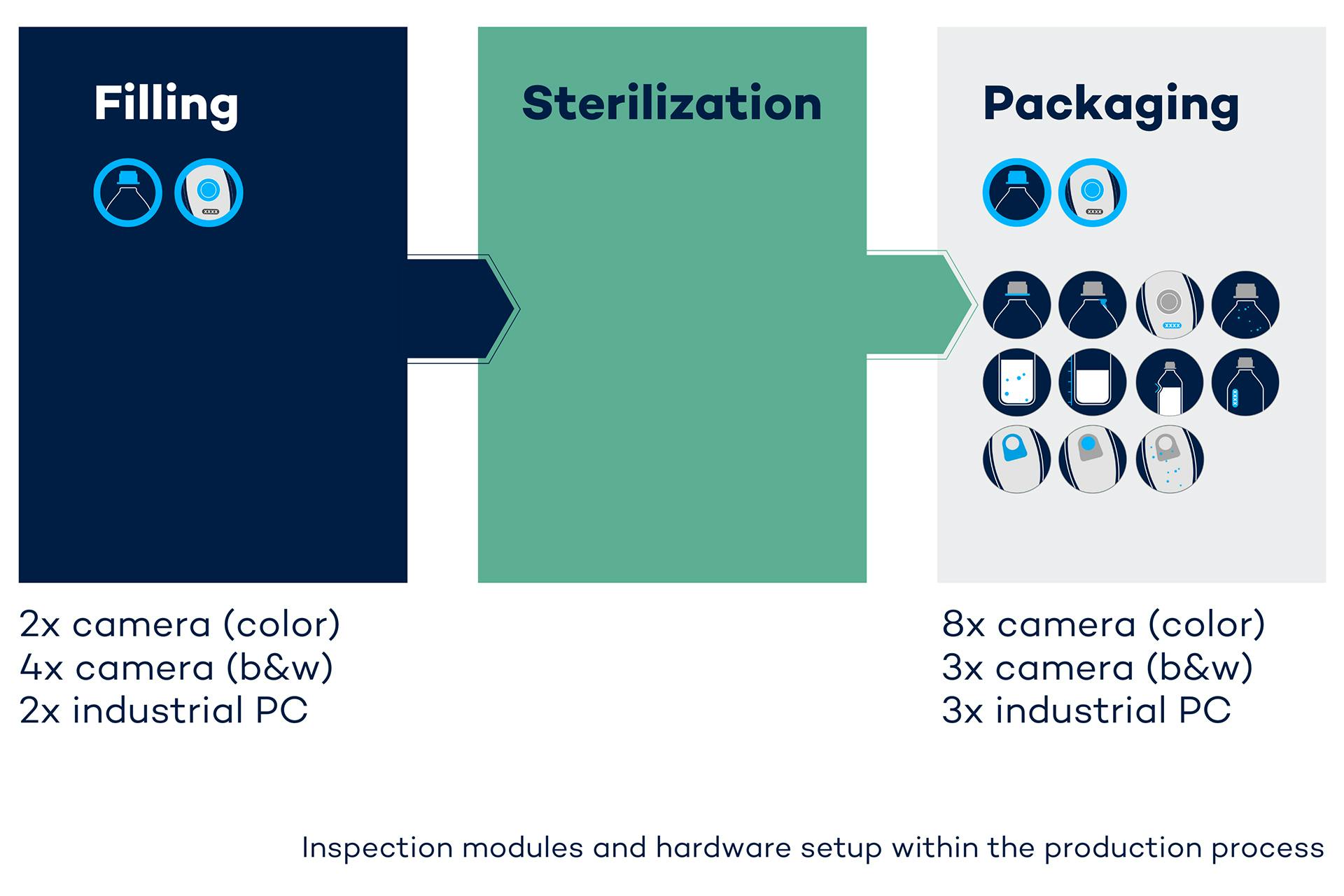

This is possible thanks to the use of 13 individual cameras, including a special 360° lens that was customized for the product. Both black-and-white and color cameras are used in the machine. This setup implements 13 different inspection modules, which inspect the individual defect classes.

Accordingly, 13 individual images are captured of each BFS container that is manufactured. With a resolution of up to approx. 2500 × 2000 pixels per camera, a large volume of data is created for each container.

Results

With the automated visual inspection solution from VITRONIC, the new production line in the packaging area achieves a maximum output of 14,400 containers per hour

This represents an increase of 60 percent compared with the previous line.

The greatest benefit for our client is that we can conduct a 100% visual inspection without losing any time and with a performance rate that was not not previously achieved at any other site.

An additional benefit

The system used here has results databases which are fed with data by the evaluation algorithms. This data can then be exported easily. Engineers in charge of production can examine these defect image memories, the analysis data, and the corresponding reject rates in order to optimize the relevant process step in the system.

Summary

The decisive, market-relevant benefit of the solution results from integrating inspection into the filling system in a way that is synchronized with the production cycle. Other conceivable solutions for the filling area, such as using a separate machine for the inspection, are costly by comparison. In this case additional buffer segments would be required, in turn making the production processes significantly longer.