Welding process optimization with WeldloopMaximum Productivity in the Welding Process

How Can You Optimize Your Welding Lines with Linked Data?

Welding process optimization with Weldloop

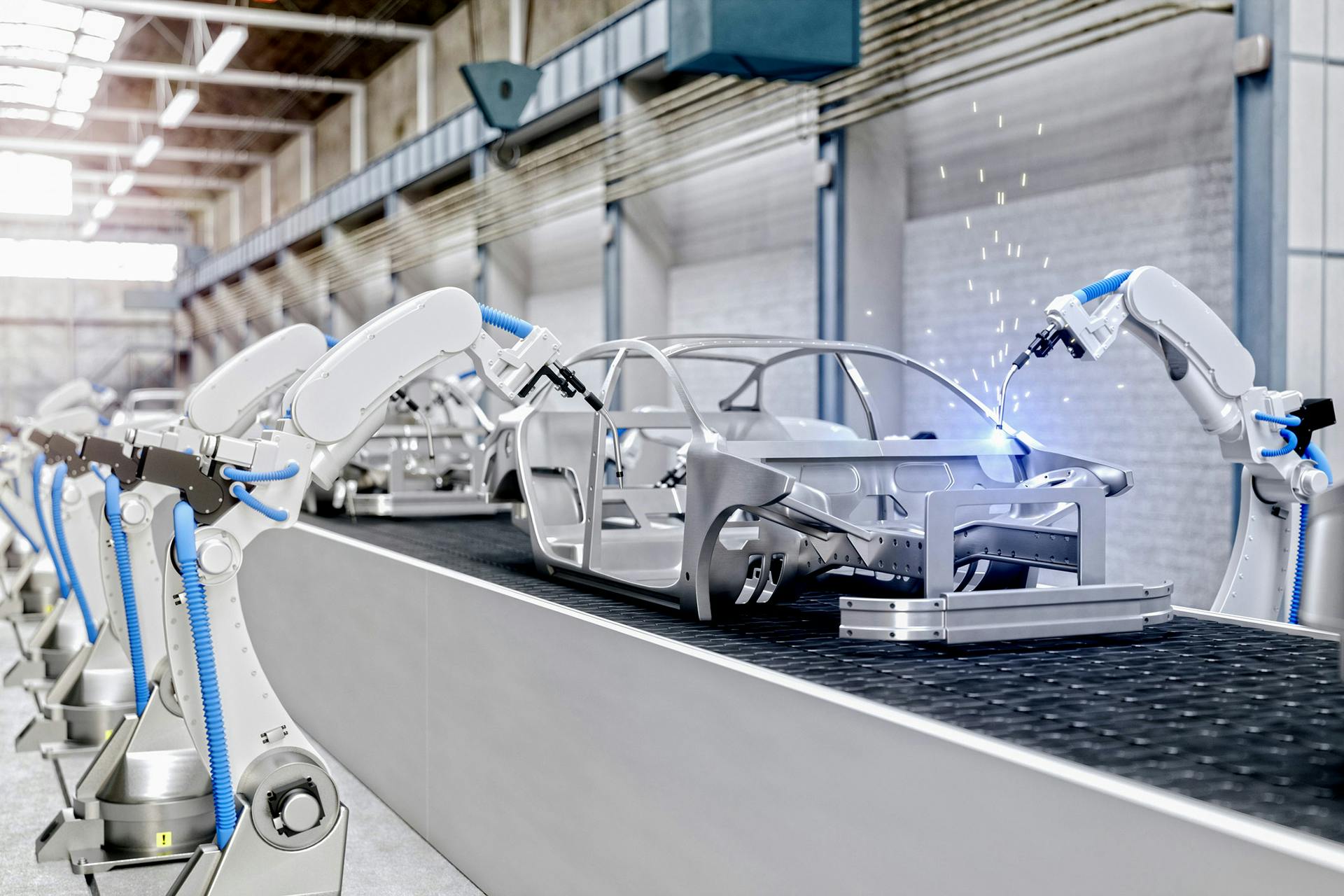

You know VIRO WSI: the automated inspection system inspects weld seams inline on powertrains, car bodies, and in the battery production process. VIRO WSI identifies even the smallest deviations and provides inspection data for documentation and process optimization.

It’s time now to take digitization to the next level: our new software solution Weldloop integrates external process data. We are now looking for fellow campaigners for pilot projects.

Our Vision

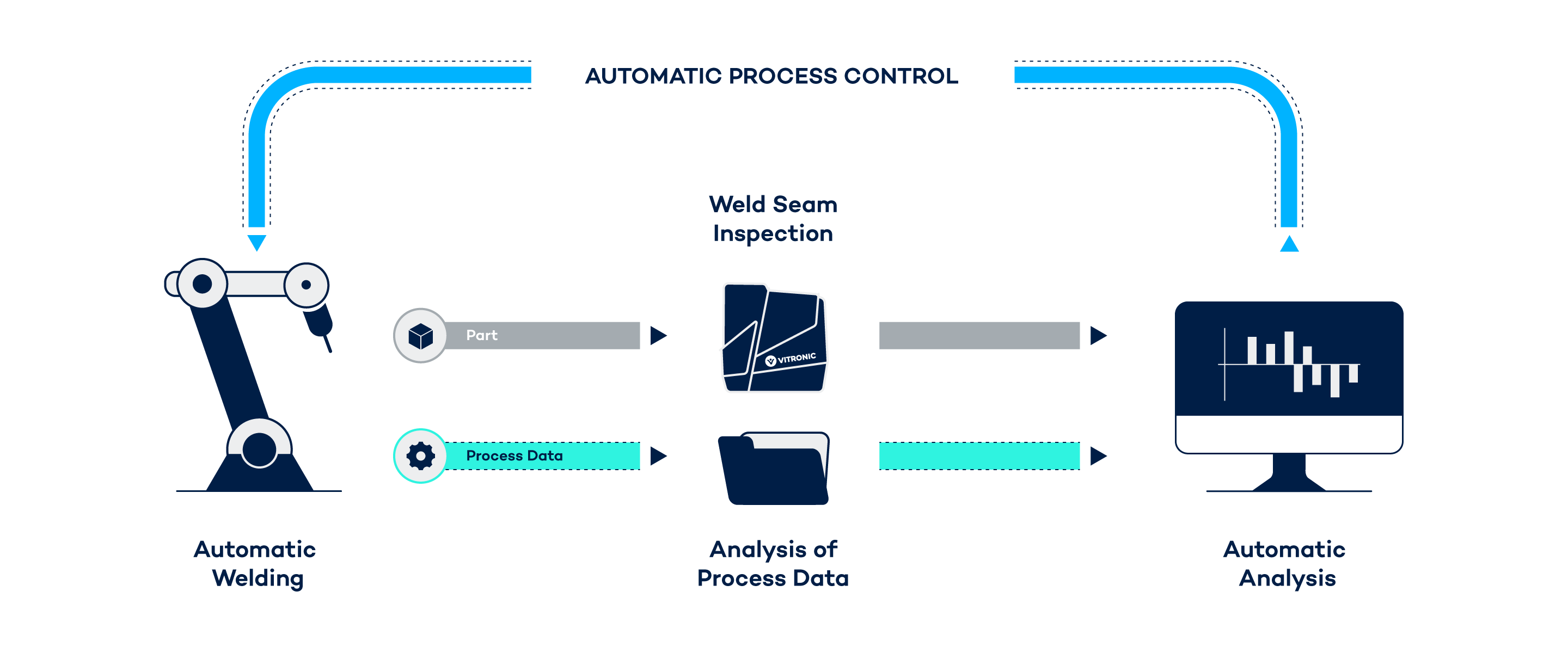

Automated process control in the welding line

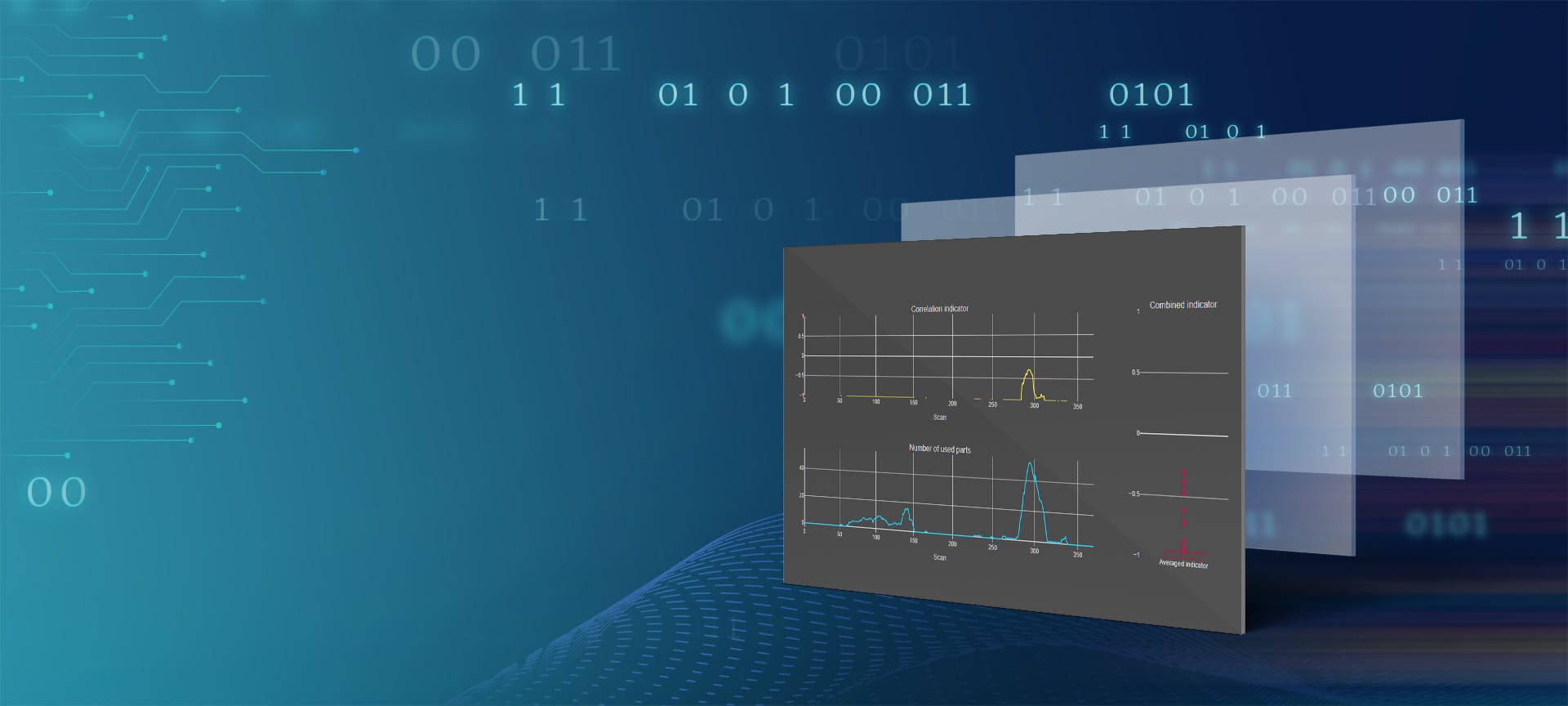

A closed loop that integrates data from various steps in the process offers greater productivity in the welding process and greater reliability in automatic quality inspection. In the future, defined processes will be carried out without human intervention, making predictive intervention possible. Our new software takes the next step toward this future.

Visionaries Wanted

Are you already using automated weld seam inspection? Do you want to take the next step with us? We offer you a chance to work side-by-side with us from the very beginning as we test Weldloop together in real world applications. Learn about what is already possible and what your pilot project could look like.