Welding process optimization with WeldloopMaximum Productivity in the Welding Process

How Can You Optimize Your Welding Lines with Linked Data?

Welding process optimization with Weldloop

You know VIRO WSI: the automated inspection system inspects weld seams inline on powertrains, car bodies, and in the battery production process. VIRO WSI identifies even the smallest deviations and provides inspection data for documentation and process optimization.

It’s time now to take digitization to the next level: our software Weldloop integrates external process data from the welding line. It enables data-driven optimization of welding and inspection processes and reduces manual operations.

Our Vision

Automated process control in the welding line

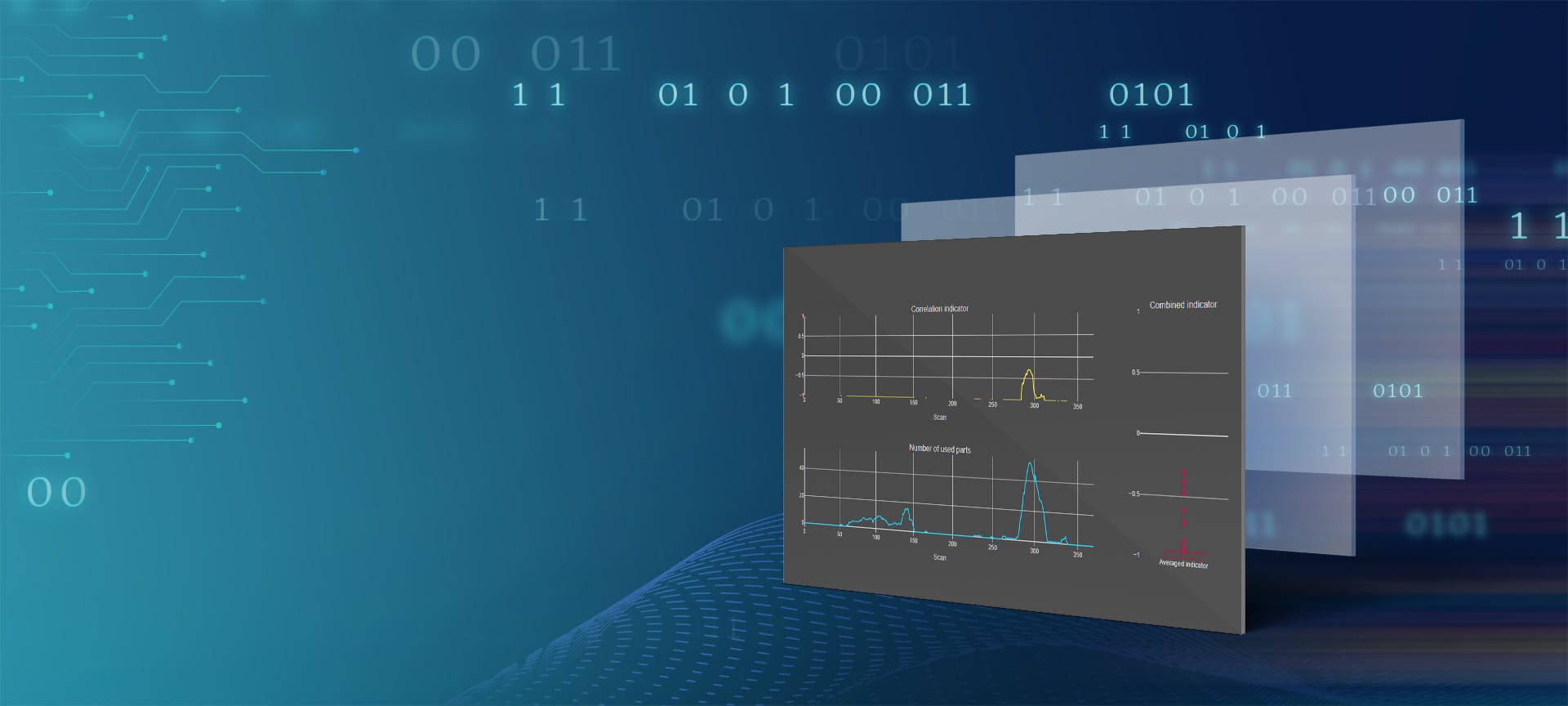

A closed loop that integrates data from various steps in the process offers greater productivity in the welding process and greater reliability in automatic quality inspection. In the future, defined processes will be carried out without human intervention, making predictive intervention possible. Our new software takes the next step toward this future.

For Fronius Weldcube

Weldloop links inspection data from VIRO WSI with process data from Weldcube Premium, the documentation solution for Fronius welding solutions. The integration goes even deeper: For example, workers can directly jump from the evaluation views to individual welding stations and adjust parameters - saving a lot of time and unnecessary manual work.

For Taking Away and Passing On

The VIRO WSI system, an integral component of VITRONIC's offerings, marks a significant advancement in the realm of welding process optimization. This automated inspection system meticulously inspects weld seams across diverse applications, including powertrains, car bodies, and battery production. Its precision in identifying even the minutest deviations is crucial for both process documentation and optimization.

Weldloop software, the supplementing solution by VITRONIC, integrates external process data from the welding line. This integration facilitates data-driven optimization of both welding and inspection processes, significantly reducing manual operations. It represents a leap forward in the digitization of the welding process, offering a more productive and reliable automatic quality inspection.

Historically, process and inspection data in the welding line were viewed as distinct entities. Weldloop bridges this gap, enabling a more cohesive and efficient process. By correlating data points, Weldloop not only improves process stability but also enhances the overall production yield by quickly identifying and correcting deviations and reducing pseudo defects.

Furthermore, Weldloop's capability extends to linking inspection data from VIRO WSI with process data from Weldcube Premium, Fronius's documentation solution for welding. This deep integration allows for seamless transitions from evaluation views to individual welding stations, enabling on-the-fly adjustments of parameters. This feature significantly reduces time and manual labor, marking a substantial improvement in operational efficiency.

VITRONIC's VIRO WSI and Weldloop software represent the cutting edge in automated inspection systems and process optimization tools for the welding industry. Their integration and data-driven capabilities not only streamline the welding process but also enhance productivity, reliability, and quality in the automated inspection welding line, making them indispensable tools in the modern industrial landscape.