Current Logistics Challenges for E-Commerce Companies

Logistics, particularly within the e-commerce sector, faces pressure from multiple crises and trends simultaneously. During the COVID-19 pandemic, e-commerce boomed and shipping volumes surged dramatically. Although the growth rate has slightly subsided, shipments from online orders remain significantly higher than pre-pandemic levels. While robust online sales are positive for retailers, it can strain logistics capacities, particularly during peak periods like the Christmas season.

In addition to logistical operational challenges, rising energy, transportation, and labor costs have become difficult for businesses to offset with higher prices or shipping charges. In the current economic climate, customers are price-sensitive, but their expectations remain high: they expect fast and preferably free delivery of their online purchases.

Retailers are not only challenged by delivery of online orders, they also experience high return rates that vary by product category. For clothing, 6 out of 10 shipments are returned. The costs of handling these returns are immense. As a result of returns, the peak season for e-commerce logistics now extends until February, putting a significant strain on infrastructure and personnel.

Generally, work in warehousing and logistics is difficult to source and scale up and down for peak season activity. It is physically demanding, and many operations run 24 hours/day. The labor shortage has posed noticeable challenges for years, even after the pandemic and supply chain recovery, and qualified personnel are often lacking.

Automation in Three Main Areas of E-Commerce Logistics

As seen across industries, the diverse challenges facing logistics operations require stronger digitalization and automation to stay competitive. What does this entail for e-commerce companies and retailers?

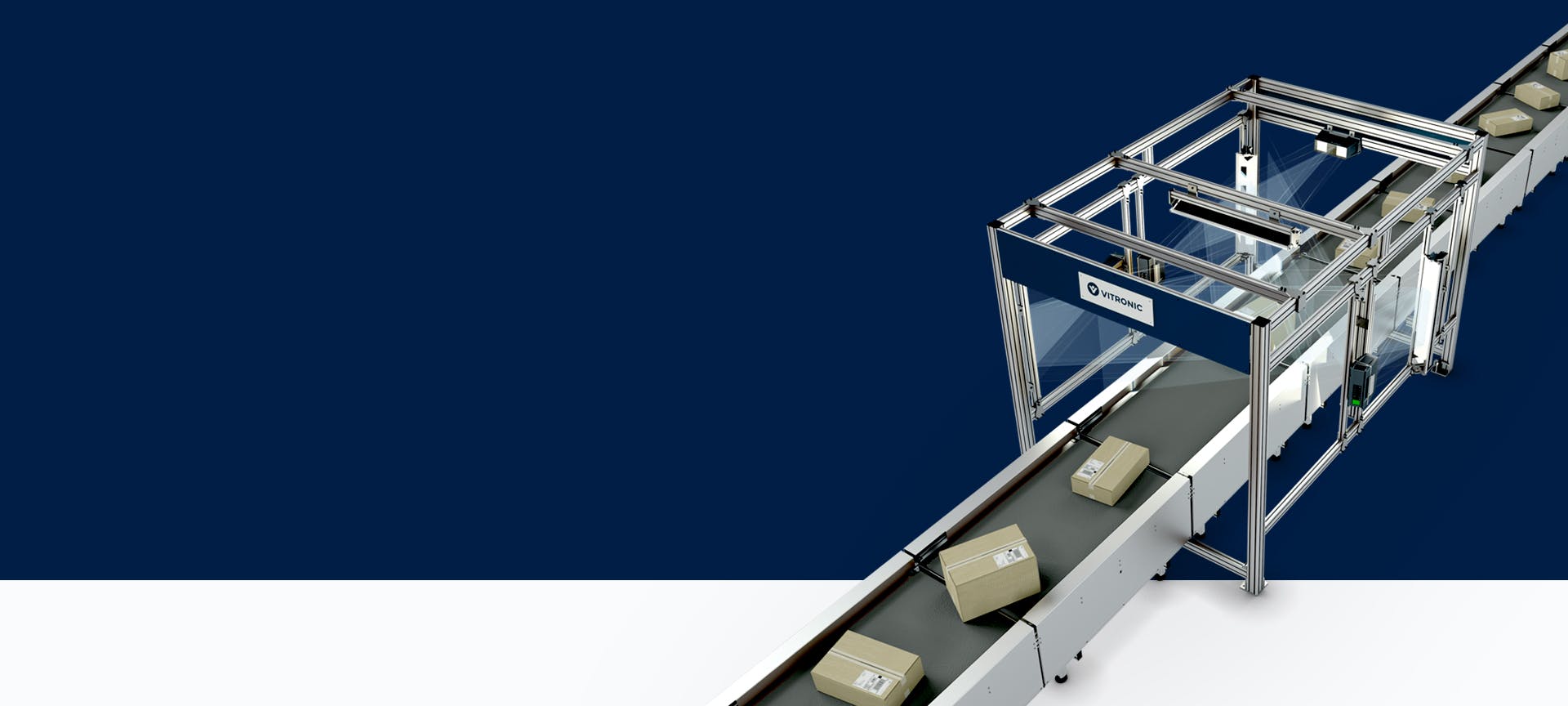

One should not envision a completely empty warehouse where robots and conveyors handle shipments on their own. Automation takes various forms, and it’s easy to start small, like with manual workstations equipped with camera sensors instead of handheld scanners, or with a sorting system that automatically moves packages into the right containers.

Logistics automation applications are always based on the same principle. Data is digitally collected from packages using sensors, including dimensions, weight, condition, labels, codes, markings, photos, and 3D images. Based on the data collected, subsequent processes like sorting and labeling can be automated, or manual processes can be digitally supported in specific areas.

What are the goals? Speeding up processing times, saving labor, making strenuous tasks easier, and reducing error rates. How do these advantages affect the three areas of e-commerce logistics?

Receiving Goods

- Intralogistics managers get immediate visibility of incoming goods.

- Incoming goods are sorted according to predetermined criteria to streamline their processing and delivery to stores or end customers.

- Issues and complaints with suppliers can be resolved more easily with item tracking and supporting evidence.

- Optimization of pallet and shelf stocking based on dimensions becomes possible.

- Damaged shipments can be identified and sorted out immediately.

Picking and Shipping

- Picking is three times faster than manual scanning of packed items.

- Data about the goods and packages can be shared with shipping providers and customers (status updates, tracking information).

- Optimization of delivery vehicle loading based on package dimensions and route planning based on delivery address become possible.

- Invoices can be automatically generated upon shipping.

Returns

- Processing returns is up to five times faster.

- Address labels, markings, and notes, like return reasons, are scanned, directly transferred to the ERP system, and associated with the original order.

- There are no more reading or typing errors during data transfer.

- The automatic recognition rate is nearly 100%.

- Problems can be resolved faster thanks to comprehensive documentation.

High Investments in New Systems and Personnel Required

Existing systems must be enhanced with the necessary capabilities, for example technologies like OCR (optical character recognition) and RFID. Equipment and warehouse management software must be able to not just capture data from camera systems, but to be able to process and use that data. While automation and digitization require significant investments, the data possibilities and process optimizations are where ROI is found.

Facing the dual pressures of increasing shipment volumes and customer expectations, these technologies serve not just as tools for efficiency, but as foundational elements for redefining how goods are received, shipped, and returned in a digital age.

Transitioning to automation can be particularly challenging for small companies that have been processing all their order shipments manually. For retail and e-commerce companies struggling to know where to begin with logistics automation, it is important to carefully evaluate which technologies best suit their specific needs. Identifying requirements, like volume, data tracking, and label types, is the best place to start. Once technologies have been identified and implemented, employees must be trained for the new systems, and new skillsets may be necessary. Tasks will shift from repetitive, manual tasks to monitoring and controlling the systems and software.

It is often time-critical for companies to adopt automation in order to remain competitive. However, it is important to not overextend and to consider proceeding in stages, transforming one process at a time. Get started by automating the processes that promise the highest or quickest return on investment.

Automation in e-commerce logistics is critical to be competitive and profitable. It creates efficiencies that also help companies be more sustainable and conserve resources. These investments made today are investments in the future. Only with automated logistics can e-commerce companies continue to grow and face the challenges of the demanding market.

Summary

In Brief:

- Automation in e-commerce logistics addresses rising shipment volumes and customer expectations efficiently.

- Digitalization enables immediate visibility and streamlined processing of goods, enhancing both speed and accuracy.

- Advanced technologies reduce labor requirements and error rates, particularly in the handling of returns.

- Investments in automation ensure scalability and adaptability, crucial for maintaining competitive edge in e-commerce.