Weld Seam Inspection in Battery ProductionIncreasing market share with quality & performance

Premium Li-Ion Batteries Thanks to Weld Seam Inspection

Weld Seam Inspection in Battery Production

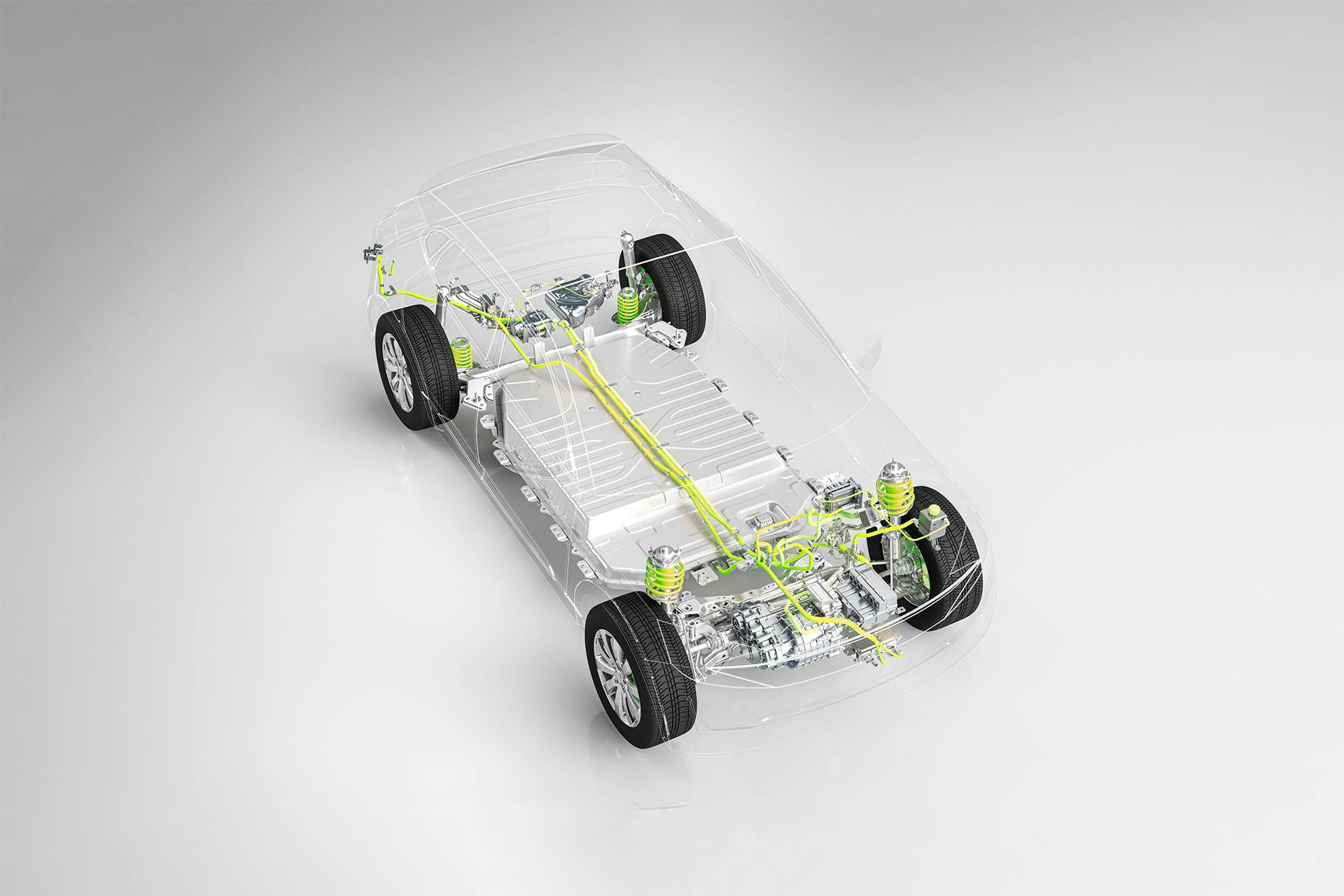

Batteries are the new engines.

Weld seam inspection ensures that only Lithium-ion batteries with defect-free contacts and cleanly welded battery modules and housings are delivered to your customers.

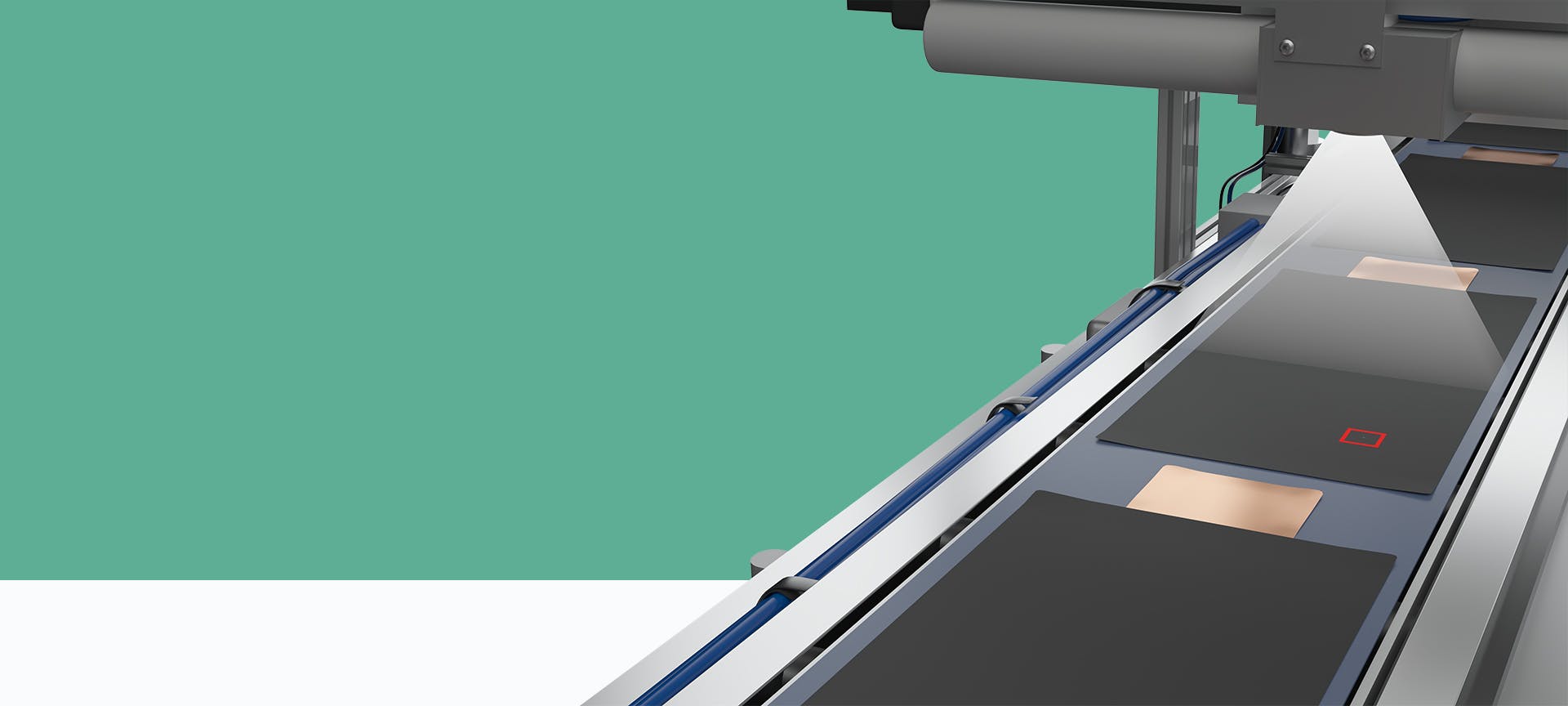

Every Cell Contact is Inspected

Defect-free contacts are essential for powerful, long-life Lithium-ion batteries. Even the slightest deviation can reduce their performance and durability. Weld seam inspection automatically inspects every weld seam on every contact and identifies the slightest irregularities. As a result, only batteries with flawless contacts and high performance data reach the market.

- 0%slippage

- 100%automatic seam tracking

Every Weld Seam Matters

Weld seams are an important element in ensuring passenger safety. As a result, rigorous requirements must be met in battery production. In cell housings, the weld seams must guarantee a hermetic seal over the entire life of the battery. Battery boxes, by contrast, are often integrated into the bodywork as a structural element. They must be stable and able to withstand a crash.

- up to 800mm/sfor long seams

Economically-Efficient Production

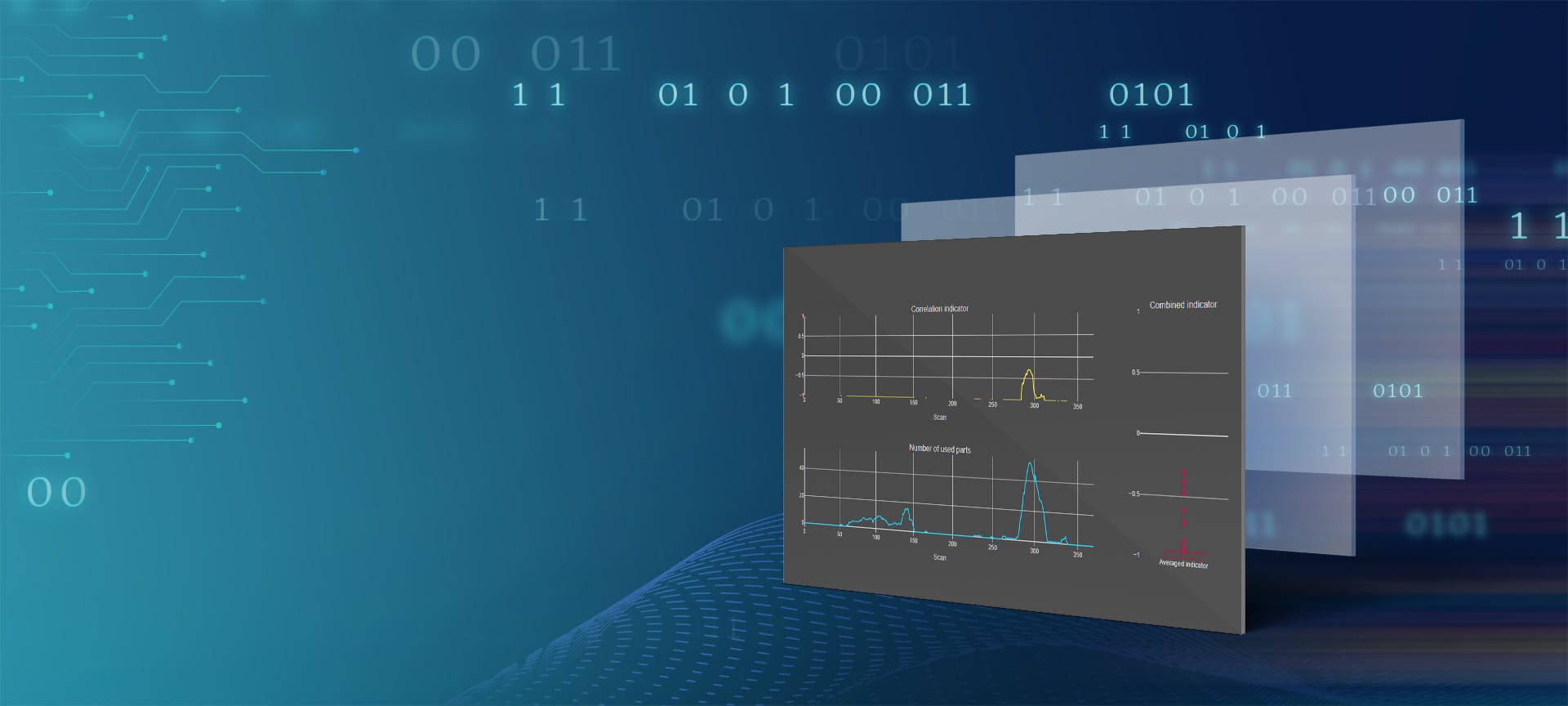

The VIRO WSI inspection system automatically documents all inspection results and stores them in an integrated database. From this data, you can immediately determine any action that may be required. In addition, the aggregation of this data serves as a valuable basis for long-term analyses. Your ever-growing database enables you to initiate effective process optimizations and implement these on an ongoing basis.

Effortlessly find and eliminate error sources

Inspection data may enable you identify errors, but it does not reveal their cause. The Weldloop software can link the data from the VIRO WSI weld seam inspection with your welding robots’ process data: trend analyses and visualizations make identifying connections effortless.

This enables you to take swift action and eliminate error sources. It also makes the inspection itself more accurate. The result: a more stable welding line plus minimal downtime and waste.

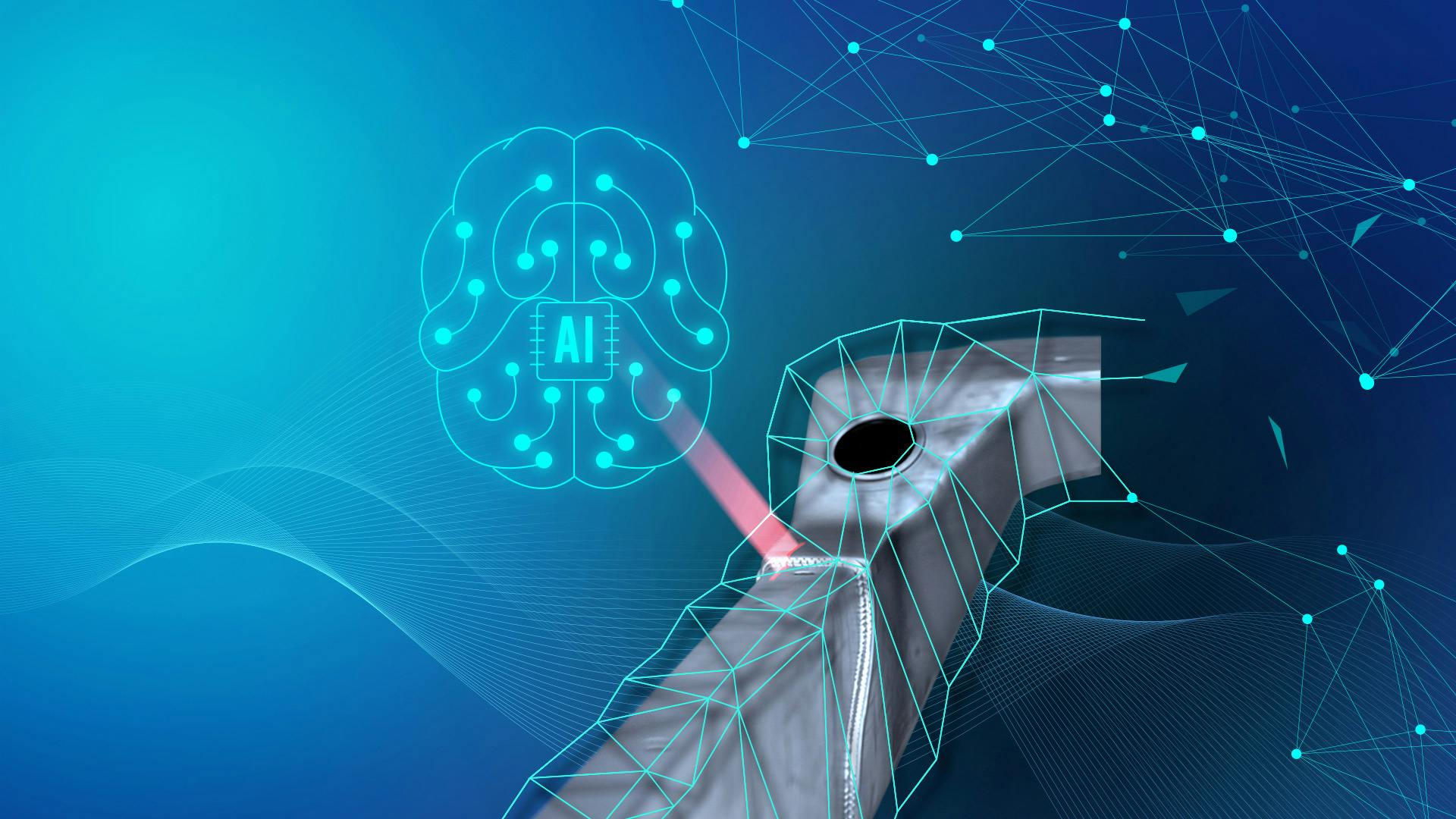

VIRO WSI Misses Nothing

VIRO WSI from VITRONIC offers maximum inspection performance for all seam types. VIRO WSI has a broad inspection range that is unparalleled in the market using inspection criteria that can be customized for a variety of requirements and applications. The solution is as easy as possible to use, with many user-friendly functions, such as parameter transfer, inspection program templates, and component visualizations.

Inspection range (a selection)

• throat thickness (A dimension)

• seam position

• seam irregularity

• object height

• porosity

• weld spatter