Surface Inspection for Battery ProductionThe Battery Booster

Higher quality and greater output in battery production

Surface Inspection for Battery Production

More Power for Your Batteries with Full Control Over Production

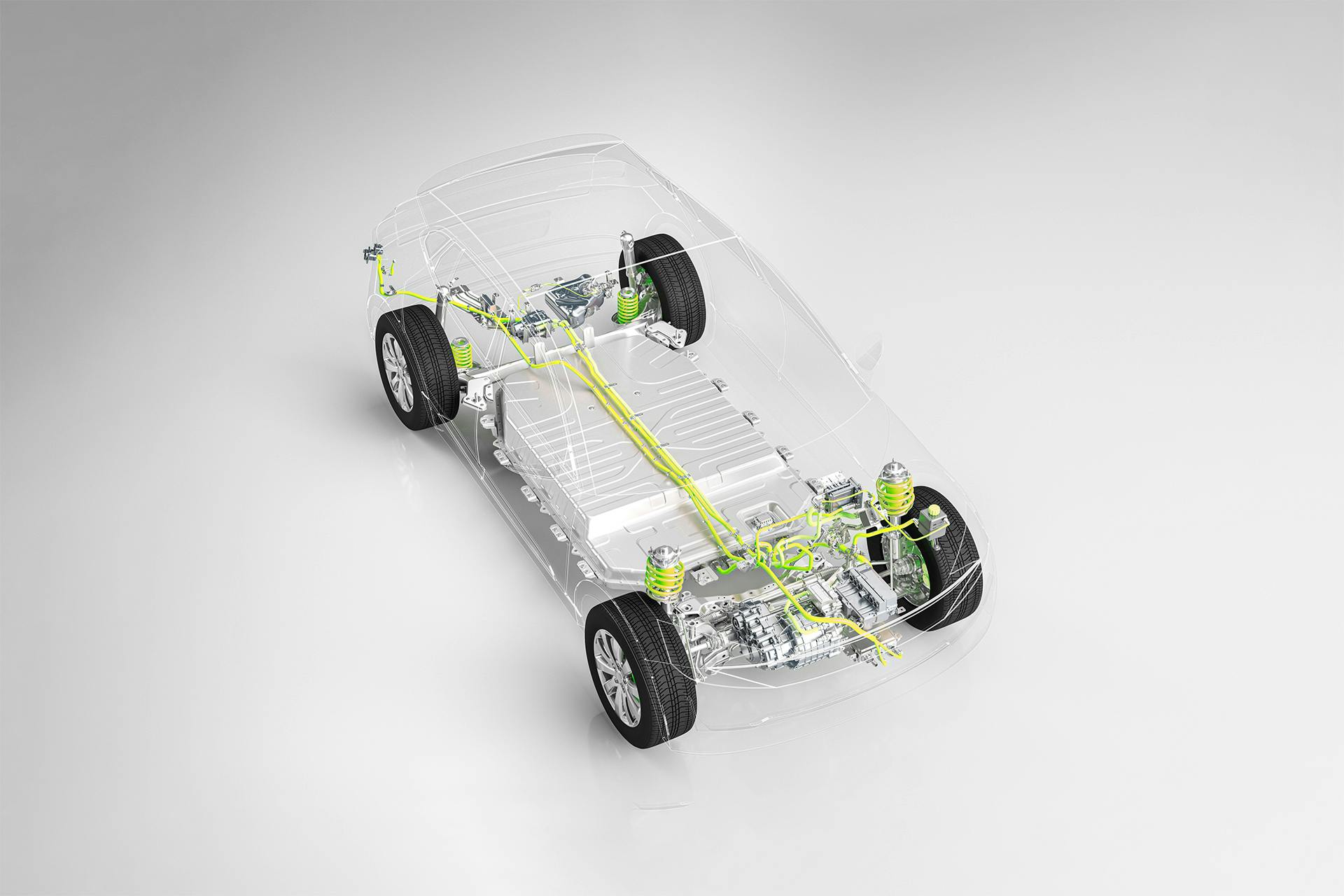

In the electromobility area, the focus is on developing higher-performing batteries. A vehicle’s range depends on the capacity of its battery. Automated quality inspection helps you meet all challenges you face in battery production and optimizes your profits. In short, it boosts your battery production.

Quality to Impress the Market

Battery technology for electric cars is still an area of huge development. Many demands are being made of battery cell and module manufacturers due to advances in technology, increasing competitive pressure and an evolving market environment.

As a battery manufacturer, you can rise to these challenges by integrated automated quality inspection into your battery production processes.

After all, if you want to assert yourself in the market, your quality standards must set yourself apart from competitors right from the start.

Consistent Inspection

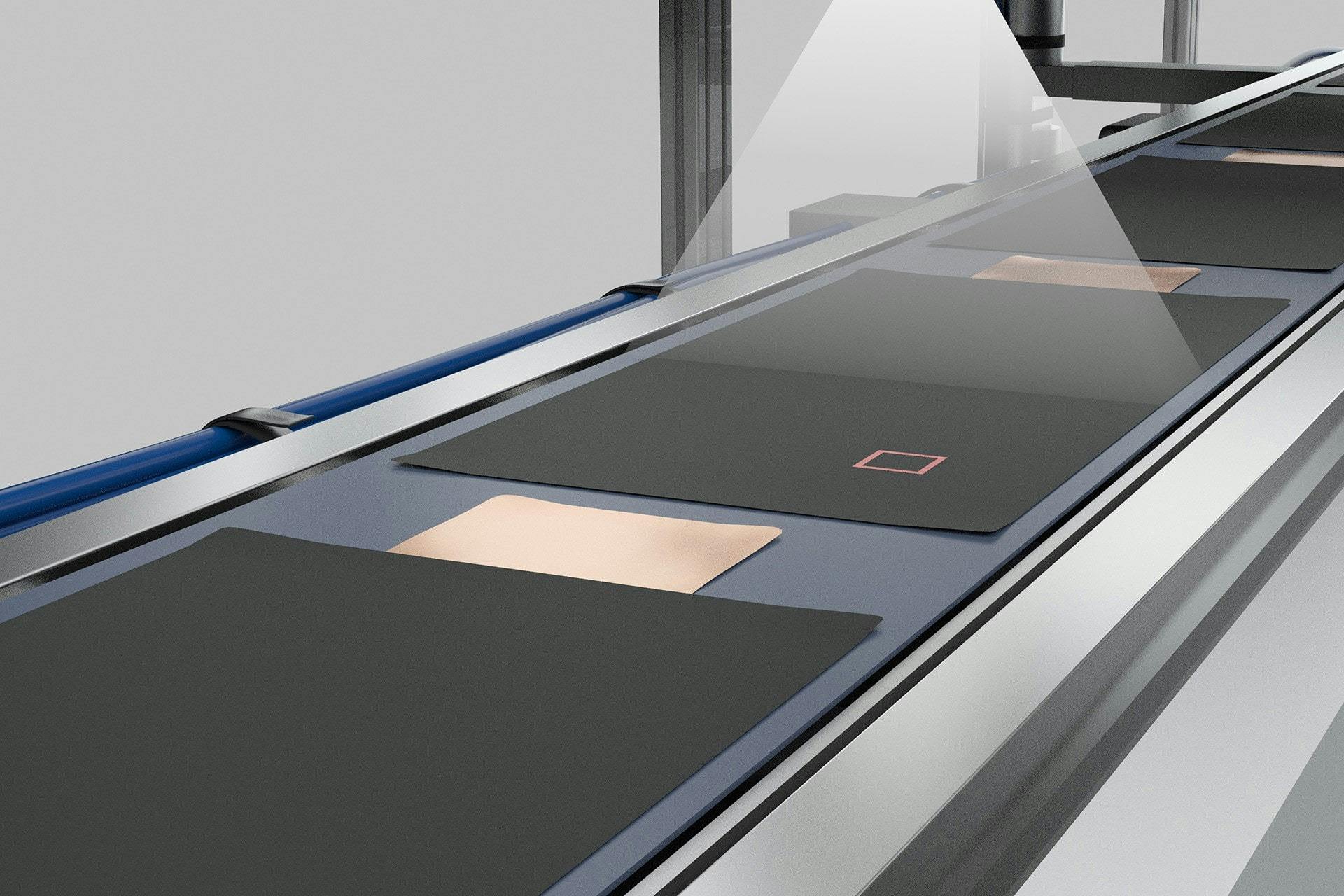

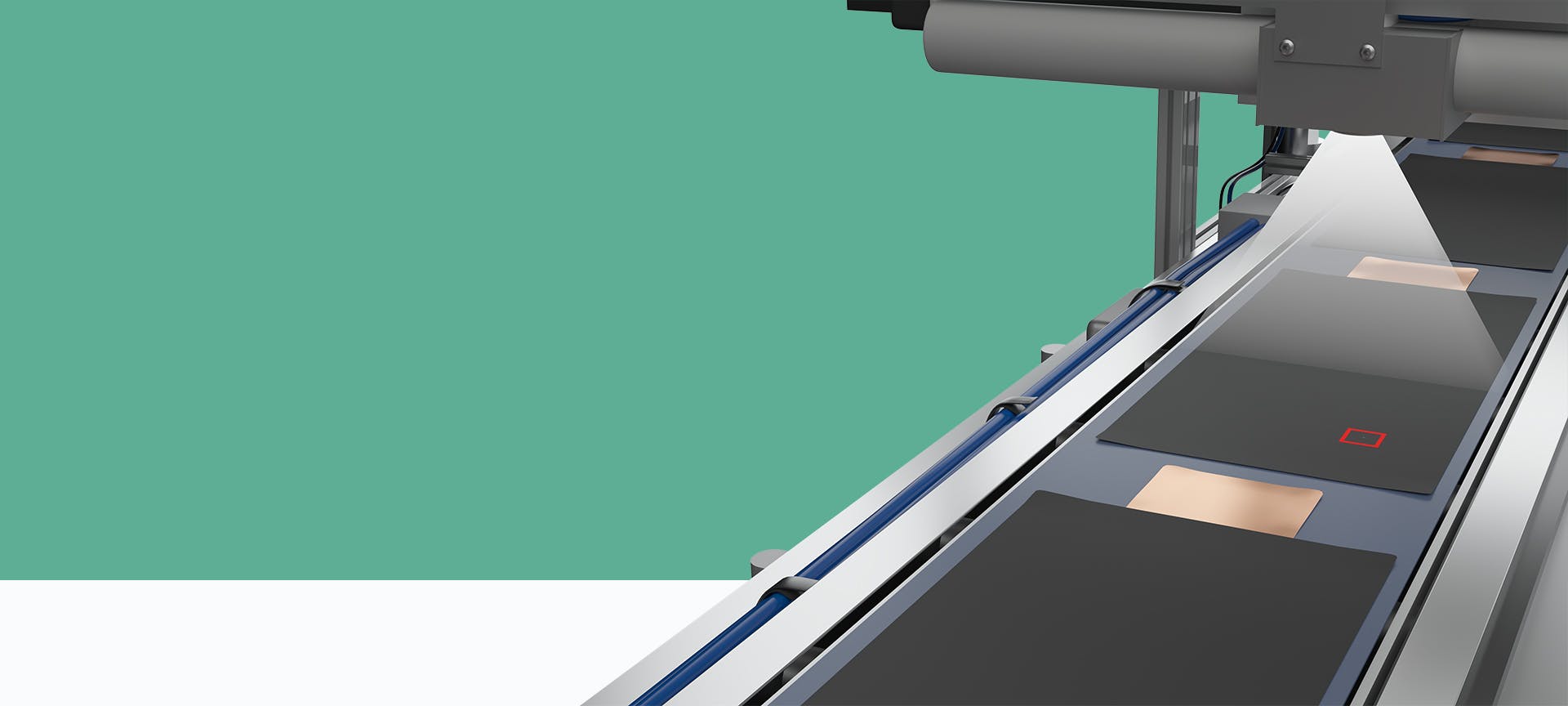

Automated battery production demands automated inspection. That’s because conventional visual inspections are inadequate in this area. Too often, the results are not objective or comparable due to human unpredictability or external influences.

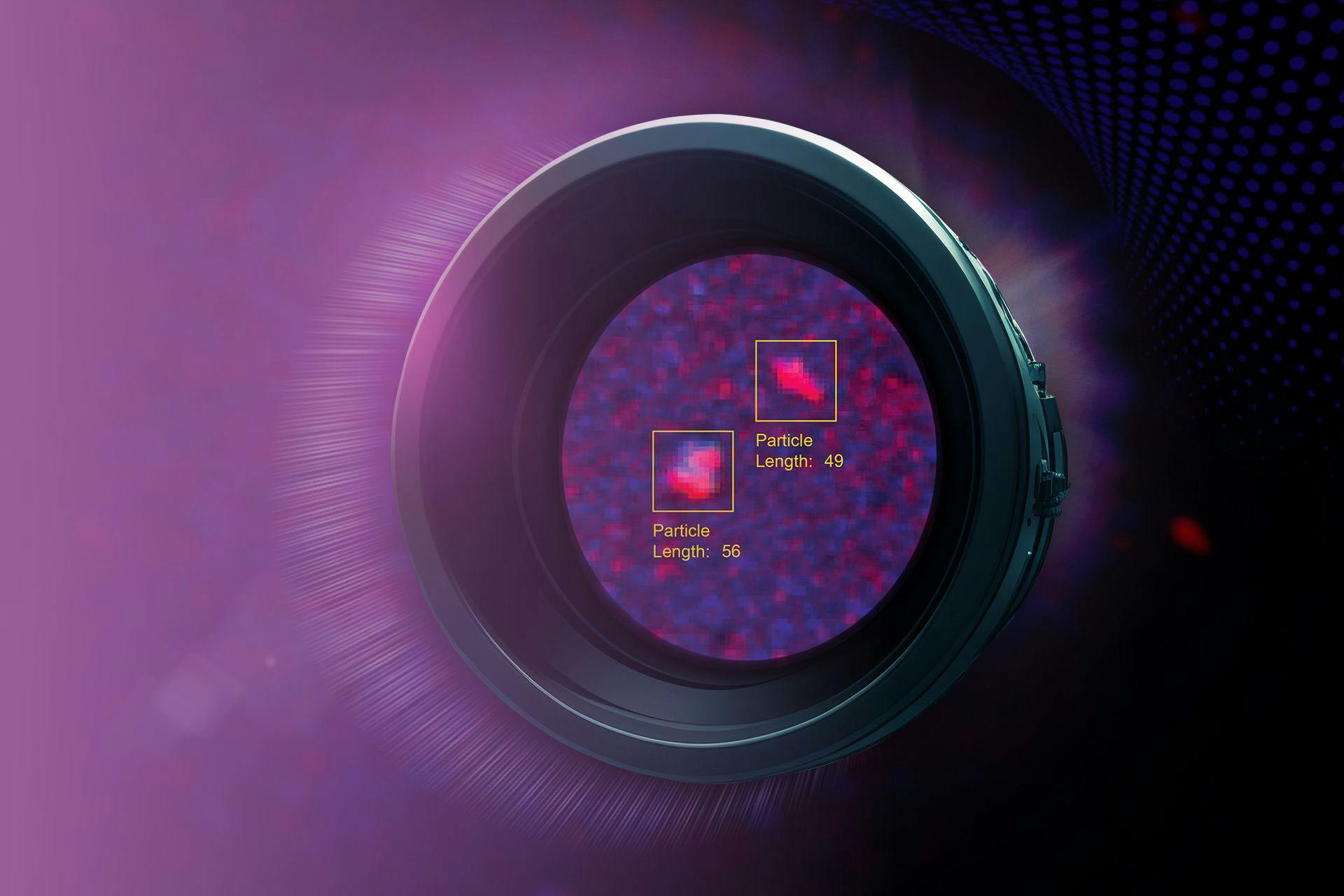

Our automated inspection systems detect every single surface detect. The end result? Flawless batteries with maximum power.

- 100%objective

- 24/7available

Higher Quality and Output

The benefits are clear. Deviations are detected immediately—at production speed. Defects are prevented from slipping through to further processing.

Which results in reliable quality for every single battery, higher output and greater cost-effectiveness for the entire production process.

- 0%slippage

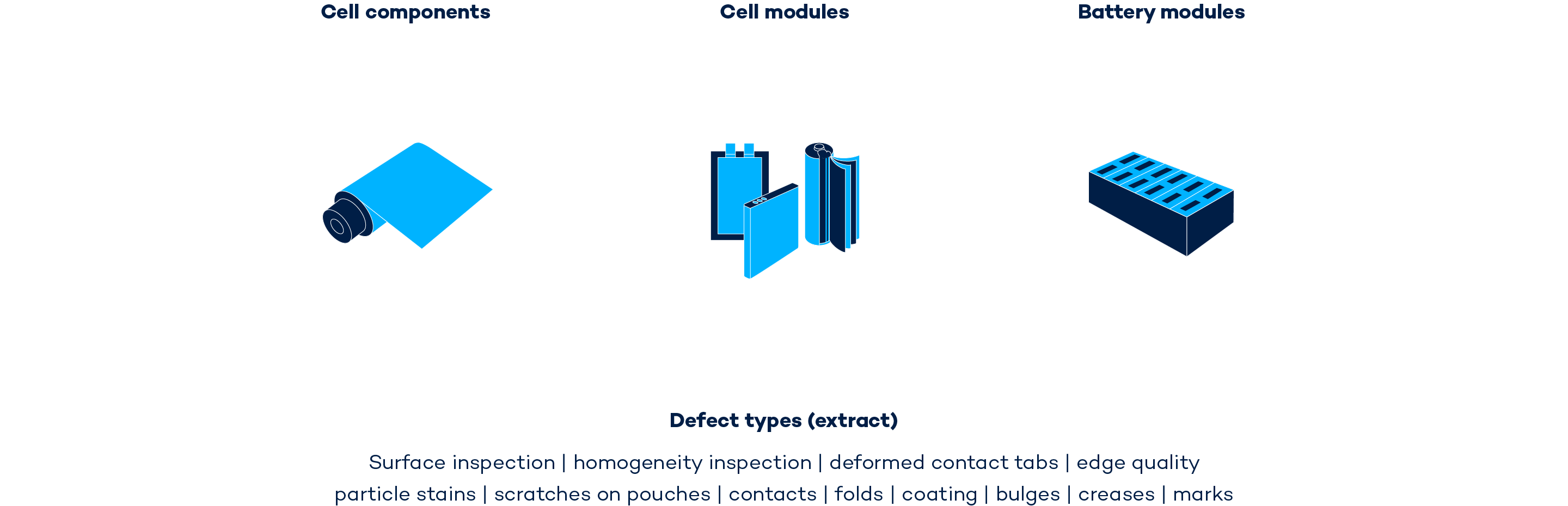

All Surfaces, All Defects

Even the smallest deviations impact quality and, in turn, the profitability, safety, and sustainability of your battery production. Our systems monitor all process steps—and do so inline without requiring you to stop production.

Optimize Processes

Each manufacturing step in battery production has its challenges—and the potential for optimization. Our inspection system documents and saves all inspection results. Based on this data, direct and lasting process optimizations can be implemented.

The goal is to reduce costs at each stage of the value-added chain and produce batteries of an increasingly high quality.

Ensure Sustainability

Every process optimization you implement in production also brings you a step closer to sustainability. That’s because you avoid costly errors, reduce waste, and save raw materials that are in short supply.

In this way, you also ensure sustainable customer relationships from the outset.