Smart ProductionTechnical Cleanliness in production and assembly

The importance of technically clean components in automotive and electronics manufacturing

What does Technical Cleanliness mean?

Technical Cleanliness is a standard in industrial production and assembly: A component is "technically clean" if it has no impurities that could impair further processing or function. The required degree of cleanliness thus depends on the part itself, the subsequent intended use and the further process steps. Undesirable particles can be chips, fibers, fluff, oxides, rust, or scale, for example.

(Filmic contaminants - such as oils, greases, and chemicals - also play a role; however, this has not yet been described under the heading of Technical Cleanliness).

Technical Cleanliness standards were first developed in the German automotive industry and later adopted and adapted by other industries, such as the electronics and medical industries.

Who defines the guidelines for Technical Cleanliness?

In the early 2000s, the German industry association TecSa (deriving from the German term “Technische Sauberkeit”) formed and developed a comprehensive set of rules entitled "VDA Volume 19 Testing of Technical Cleanliness - Particle Contamination of Functionally Relevant Automotive Parts." It describes "procedures for extracting particles from the component surface, analytical procedures for measuring, and documentation of test results." The revised version VDA 19.1 has been valid since 2015.

In addition, the guideline VDA 19.2 was published in 2010, entitled "Technical Cleanliness in assembly - environment, logistics, personnel, and assembly equipment". It is intended to help plan and optimize processes in such a way as to prevent contamination in the process chain.

In 2007, the international standard ISO 16232 was published, which is fully compatible with the German standard VDA 19.

The German ZVEI: Association of the Electrical and Digital Industry has published its adapted set of rules under the name "Technical Cleanliness in Electrical Engineering (Guide)". For the medical industry, the standards are documented in the manual of the Association of German Engineers VDI 2083 Sheet 21 "Cleanroom Technology - Cleanliness of Medical Devices in the Manufacturing Process".

Why is Technical Cleanliness important?

Dirt particles or films on components and assemblies can cause damage, from merely annoying to fatal. They may impair the function or service life of…

- the components themselves when they are later in operation.

- other parts of the system in which they will later be used (for example, in an engine).

- the equipment in the further production and assembly process.

In mechanical systems, this can cause bearings and sliding surfaces to jam, filters and nozzles to clog or valves to block. In electronic components, contamination can cause short circuits, voltage flashovers, and leakage currents or isolate contacts.

Dirt particles are often harmless to the components themselves, but can cause damage elsewhere; for example, in fluid circuits (in the case of fuel and coolants) if they are washed into filters and valves. In another article, you will find a detailed example of the danger that particles can pose in an e-car battery.

The more complex and sensitive components are, the more relevant Technical Cleanliness becomes. Modern, fuel-efficient engines, for example, are much more susceptible than older models. In vehicle assistance systems, even a single particle of dirt on a camera sensor could lead to errors and trigger a fatal accident.

How can the Technical Cleanliness be established?

Contamination on components can basically come from three different sources:

- They arise in the company's own production and assembly process and are carried over into the downstream process: for example, by sawing and milling (in metal-cutting production), or by abrasion, spatter and so on.

- They are entered into the company's own process by parts purchased from suppliers.

- They are introduced into the company's own process from outside, for example through the air or in the clothing of employees.

Foremost, the respective limit values must be defined in the development: What degree of cleanliness is required? Depending on this, appropriate measures can be taken.

Prevent carryover in your own process: Usually, components are cleaned after the corresponding processing steps: They are washed if they are allowed to come into contact with liquid; otherwise, for example in the case of electronic parts, dirt particles can be aspirated.

Prevent entry by purchased parts: If parts are supplied, either the supplier must guarantee Technical Cleanliness, or the parts must be cleaned before they are used in further processing.

Prevent entry from the outside: The assembly of components can be carried out in clean rooms; air filtration, airlocks, special transport systems, protective clothing for employees and other measures prevent components from being contaminated by entry from the outside.

To ensure Technical Cleanliness, the entire process must be taken into account, including transport and packaging. Qualified, conscientious employees also play a major role. If production or assembly is planned from scratch - for example in a new gigafactory - Technical Cleanliness should be considered from the outset in all planning steps.

How can components be tested for Technical Cleanliness?

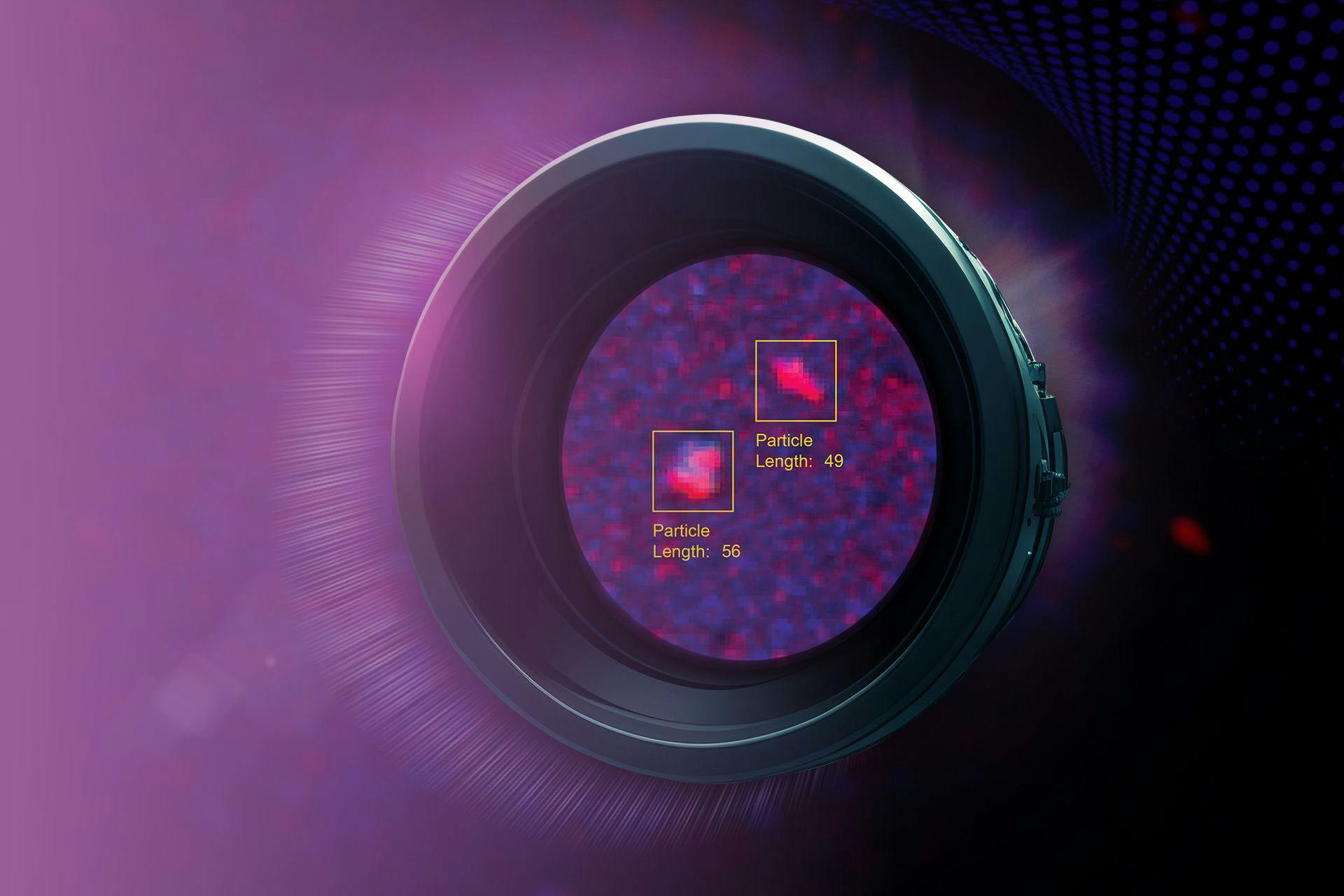

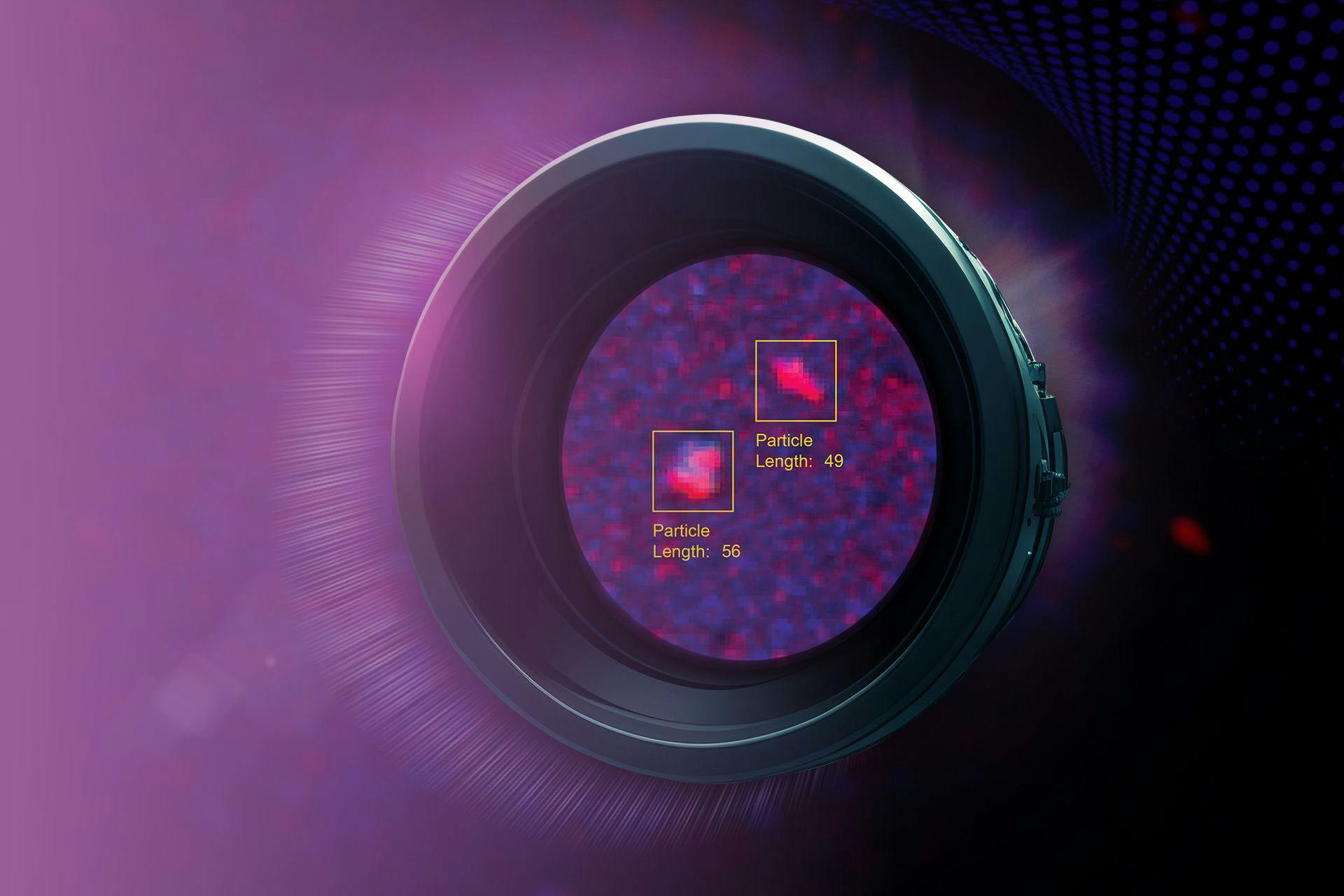

To be able to plan measures and assess their effectiveness, the components must be inspected for contamination; dirt often remains inside components in places that are difficult to access. Therefore, spot checks are carried out in the laboratory: The component or the extracted residual dirt is captured with a microscope or scanner and analyzed and classified using image processing. However, random samples are only meaningful if companies can maintain stable, reliable processes and thus consistent quality.

On the other hand, other solutions are used to inspect more accessible areas on components: Camera sensors scan each individual part directly in the production or assembly line; if residual dirt above the limit values is detected, the part can be sorted out or cleaned immediately. Areas of application for this include the assembly of battery cells or battery housings on electric cars.

Further information: Particle detection solutions for battery modules

We thank for the kind support in the preparation of this article:

Fraunhofer Institute for Manufacturing Engineering and Automation IPA

Mr. Dr.-Ing. Markus Rochowicz, Group Manager Purity Technology

Conclusion

IN SHORT:

- Components are "technically clean" if they do not have any impurities that impair their function or further processing.

- Various measures are taken to prevent dirt particles from entering and being carried along the process chain.

- Components are tested for cleanliness in the laboratory or directly in-line.