Weld Seam Inspection for Axle Components Safety Instead of Recalls

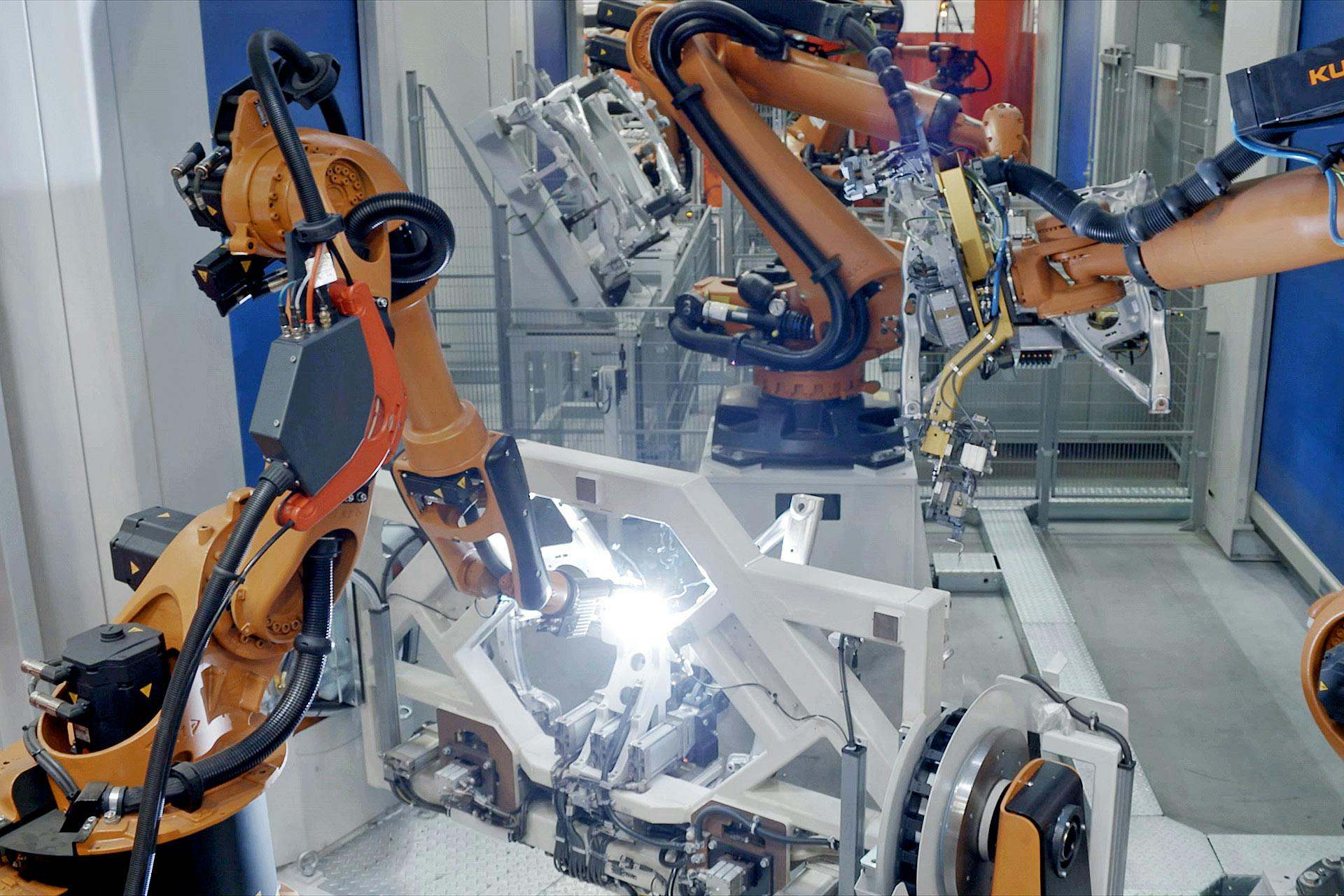

Flawless Axles Thanks to Automated Weld Seam Inspection

Weld Seam Inspection for Axle Components

Greater Production Safety in Axle Manufacturing

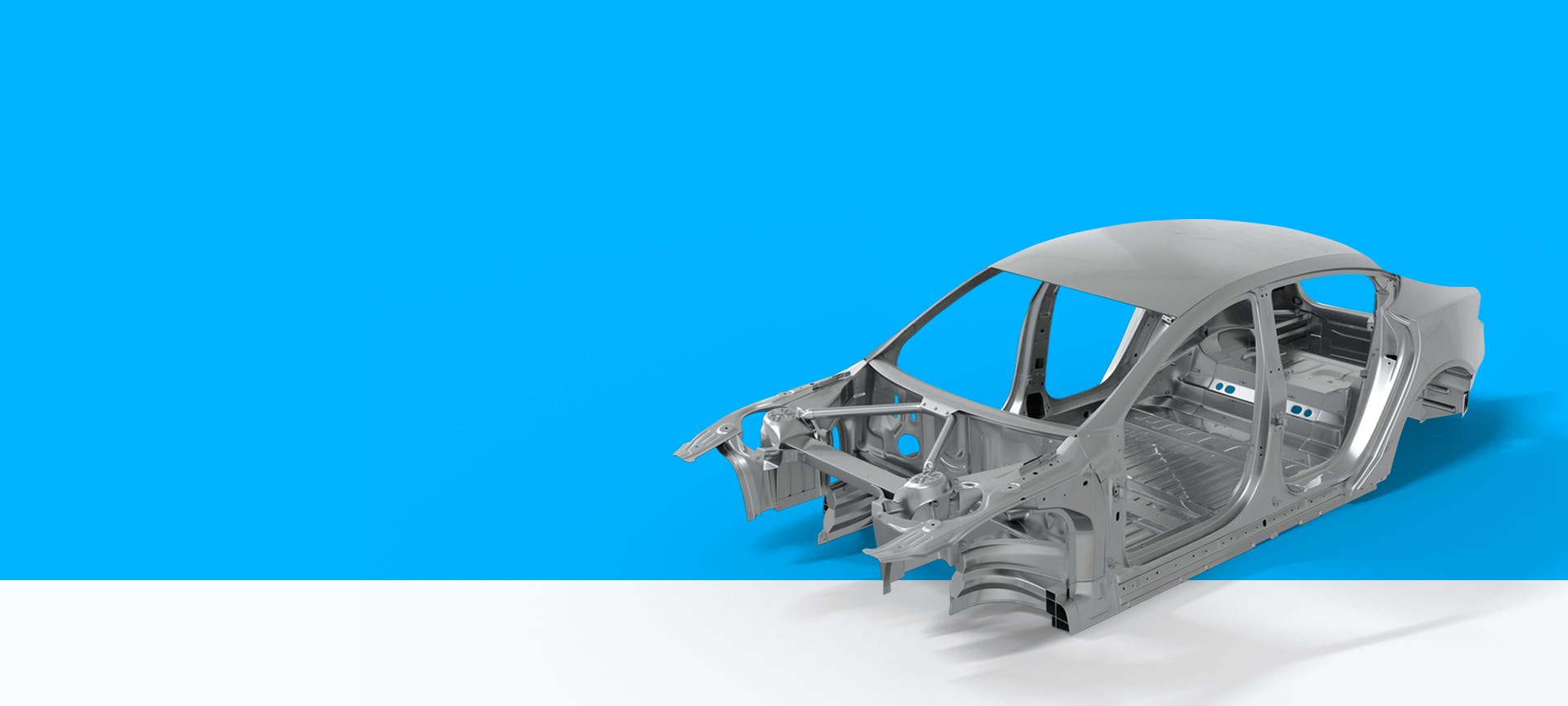

Axle beams and transverse control arms are essential elements of a safe chassis subframe. Their quality is critical to the long-term safety of vehicle occupants. Automatic weld seam inspection identifies every weld seam defect. As a result, only defect-free axle components reach further processing stages.

Finding Defects Beats Processing Them

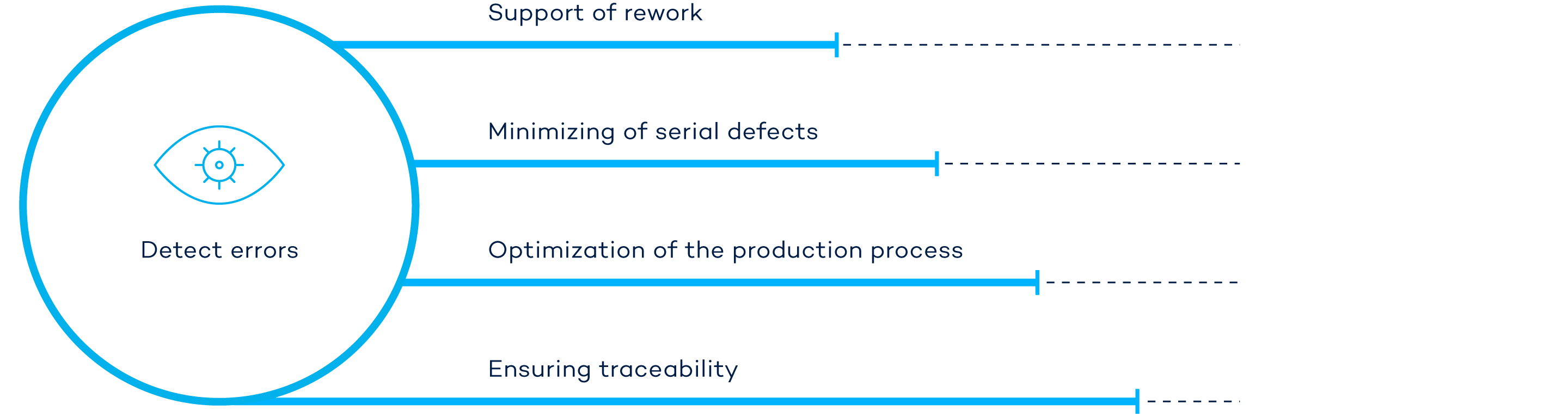

The VIRO WSI weld seam inspection solution detects the smallest defects – immediately after welding. This prevents defective axle components from being sent for further processing, which in turn eliminates unnecessary costs and use of materials. Serial defects are also detected at an early stage and defect accumulation is prevented by swift intervention in the manufacturing process.

- 0%slippage

Automated Inspection Takes a Closer Look

Today’s cutting-edge technology uses automated welding. Quality is enhanced even further when the inspection of weld seams is also automated. That’s because automated weld seam inspection is always reliable, regardless of its environment. In addition, it automatically documents product quality.

- 24/7Maximum availability

- 100%objective

Optimizing Processes

All inspection data is stored in an integrated database. As a result, subsequent tracing is easy. Data aggregation serves as a valuable basis for analysis. Process optimizations can be initiated based on a solid pool of data and can be implemented on an ongoing basis. Component quality is enhanced, waste is reduced, and production line output increases.

Immediately find and eliminate error sources

Inspection data may enable you to identify errors, but you still have to determine their cause yourself. The Weldloop software can link inspection data from the VIRO WSI system with your welding robots’ process data: by performing trend analyses and visualizations, you can effortlessly identify connections.

This enables you to take immediate action and eliminate error sources. It also makes the inspection itself more reliable. The result: you improve the stability of the welding processes and minimize downtime and waste.

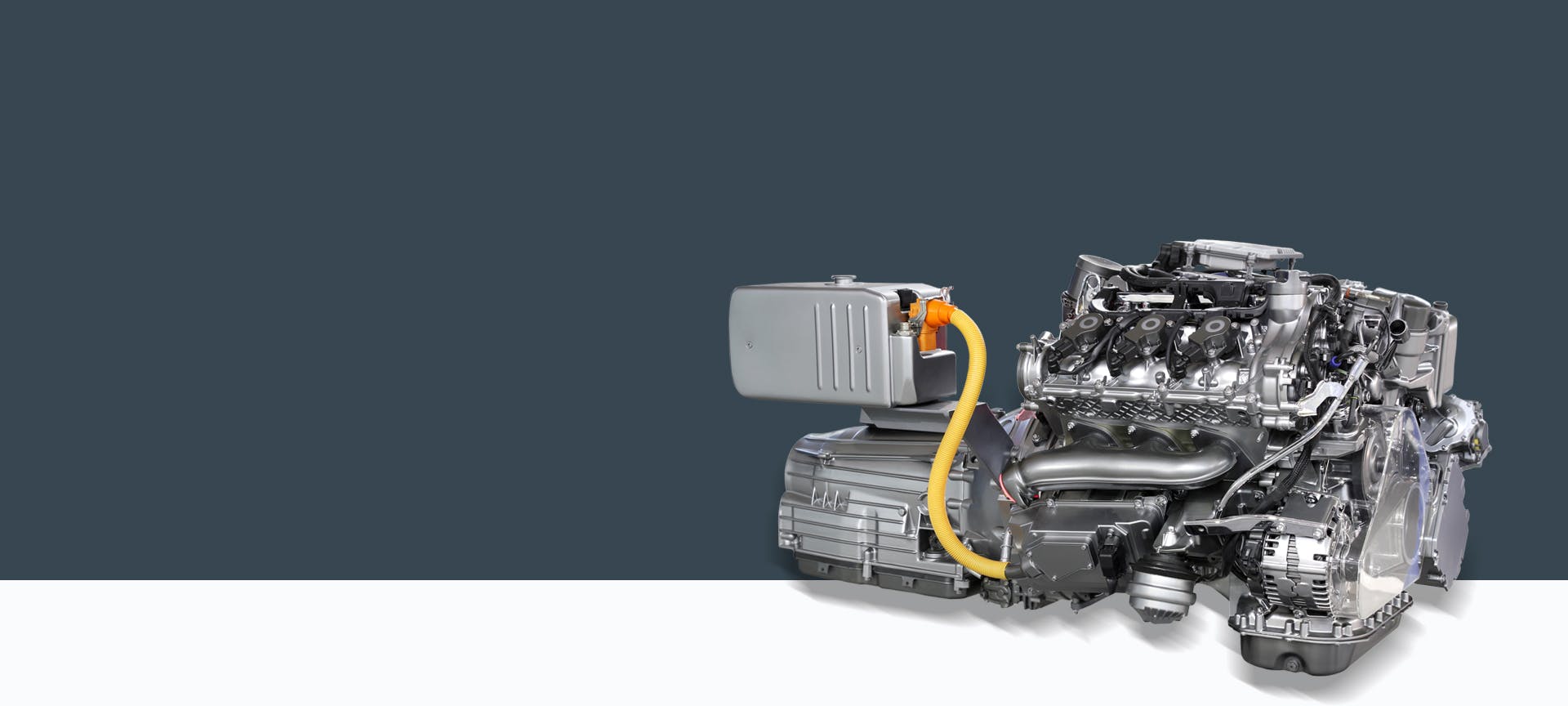

Efficient Rework

Inspection data is clearly presented to the relevant production line operatives at interactive visualization stations. As a result, manual rework stations can be integrated into the process. The integration of automated rework is also possible. VIRO WSI assigns defective components to rewelding and, thanks to specially developed software algorithms, passes on the data to ensure precise rework.