Process Automation in Battery ProductionAutomated Production – Automated Inspection

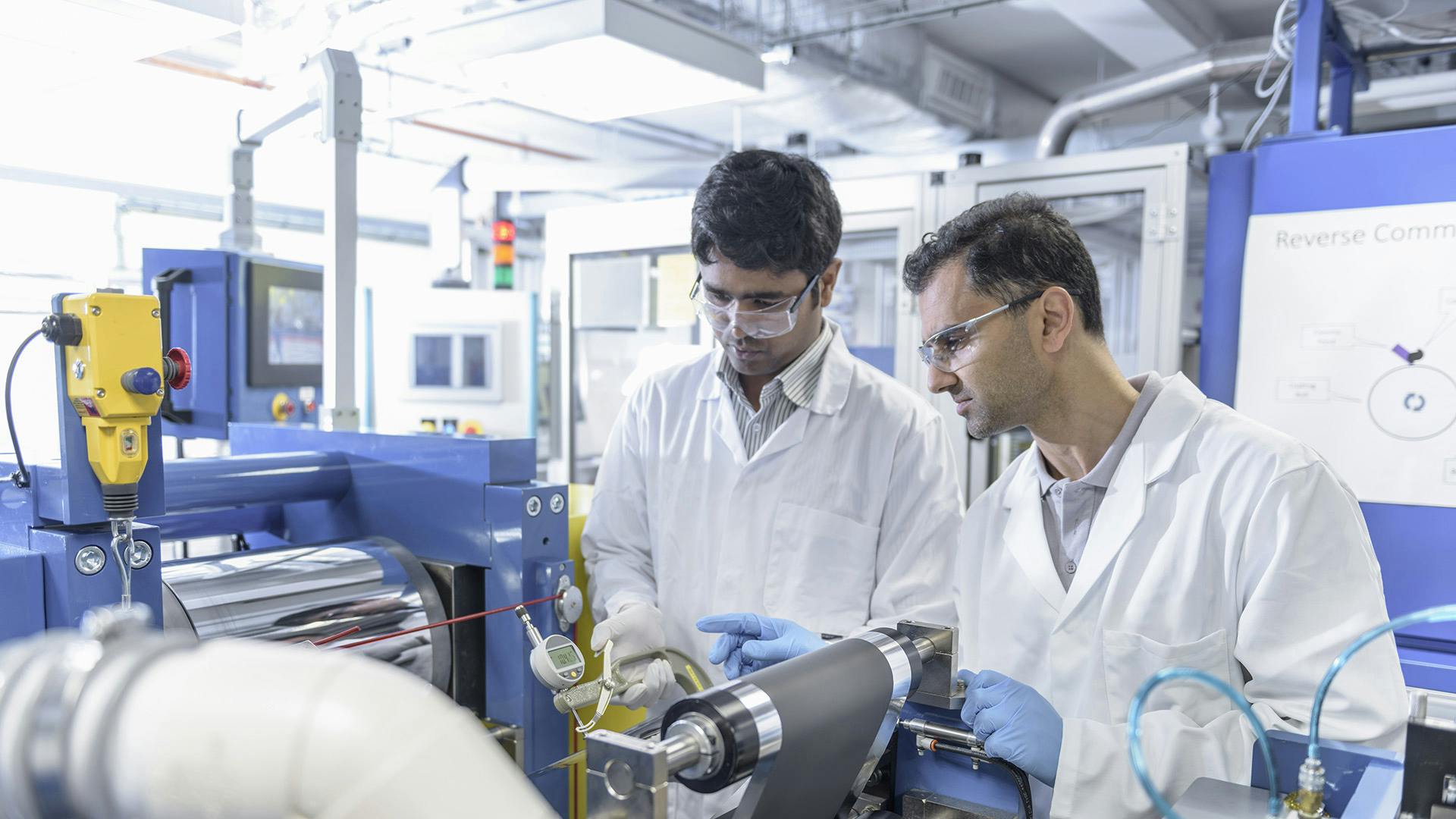

Quality and Stability in Battery Production

Process Automation in Battery Production

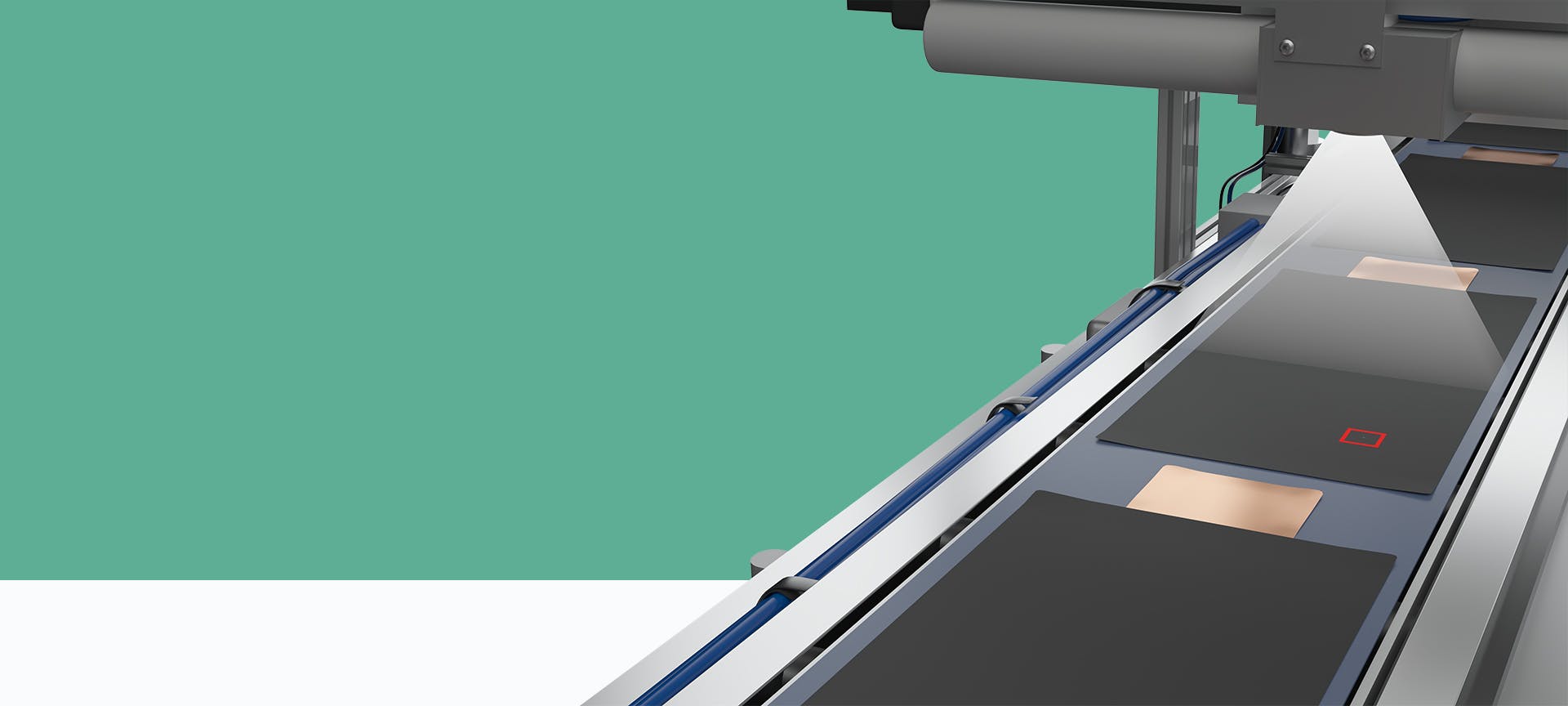

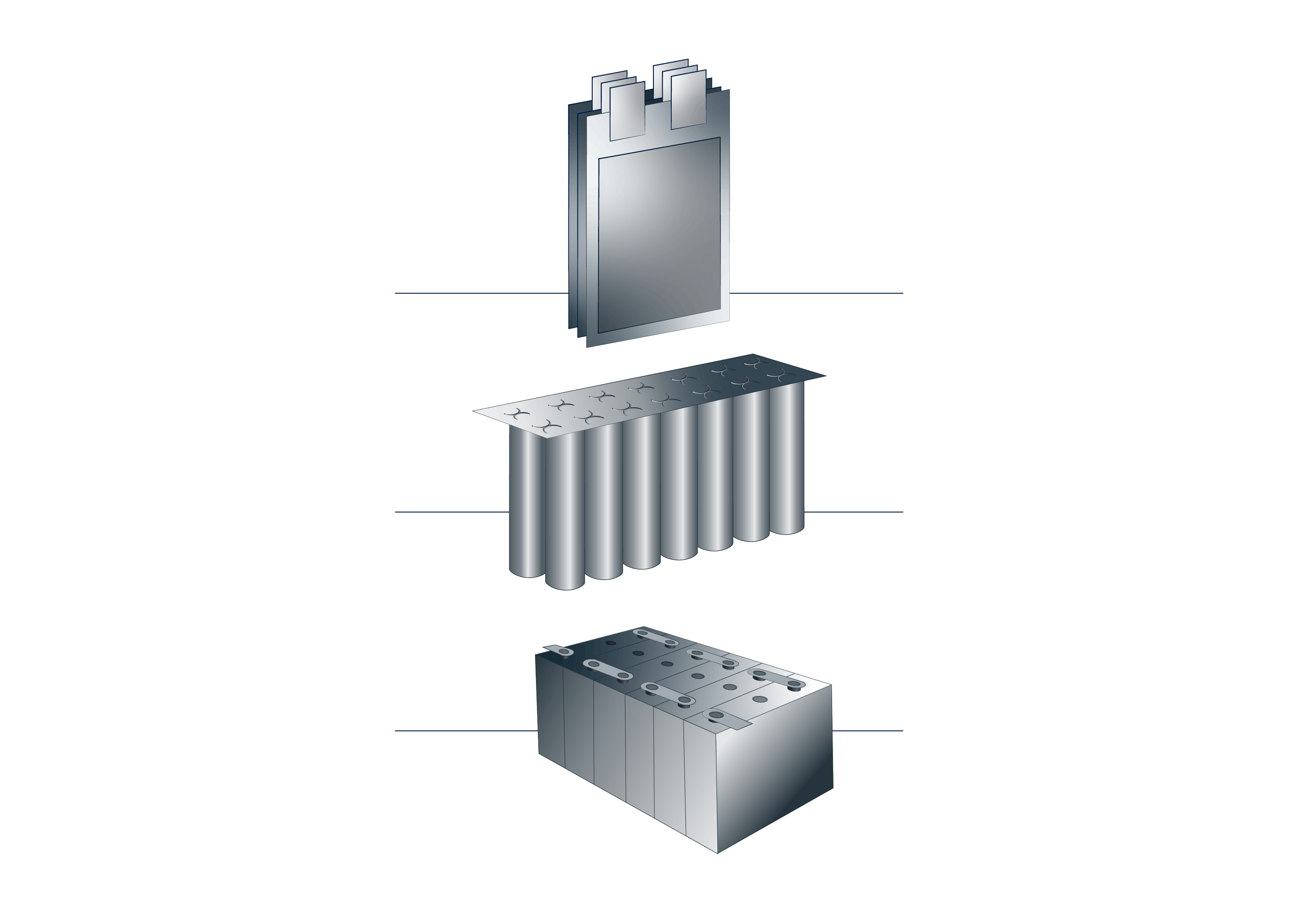

Automated assembly inspection for battery modules and battery packs

The electromobility market continues to expand, as does the demand for powerful lithium-ion batteries (LIB). As a planner and production manager of assembly lines or a producer of battery modules and packs, you are under intense competitive pressure.

Automation and digitalization are key here. Our inspection systems for battery production offer both, and help you gain the competitive edge in one of today's largest markets of the future.

All Components up to Assembly

New production technology and ever-increasing technical requirements rely on process-integrated solutions for quality control and process optimization. VINSPEC, the automated inspection system, is integrated inline to inspect the quality of components, ensuring error-free assembly of modules and packs, even at high cycle rates.

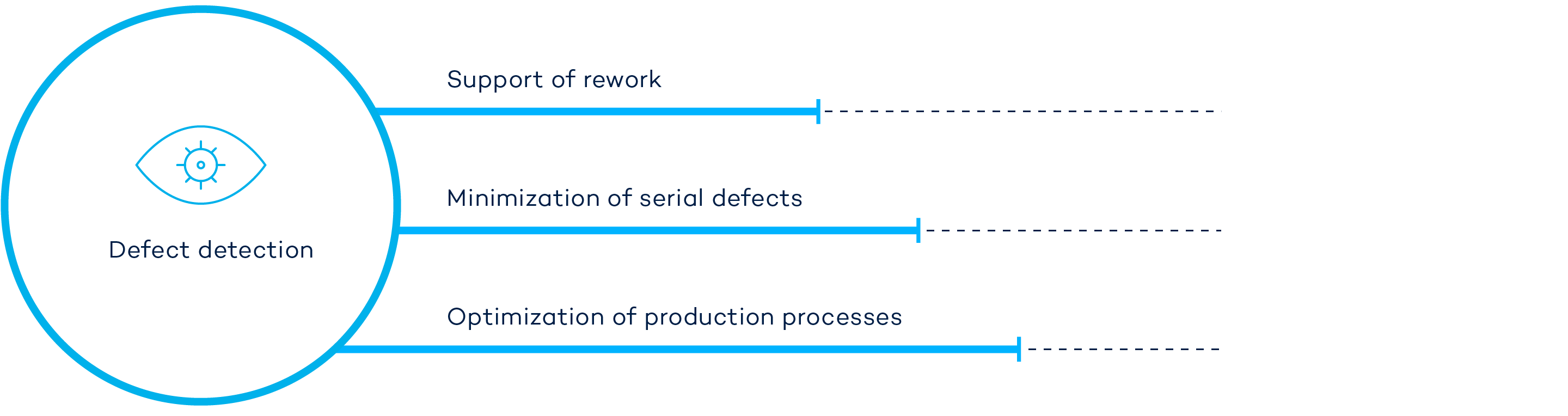

Why Check Quality?

Zero Defect Strategy in Assembly

Deviations that are found as late in the process as the electrical final inspection or in the vehicle can often be rectified only at a great expense. A company's image is at risk. Occasionally, the cost of rectifying a defect is prohibitively high because the cause must first be identified and then manually corrected.

Our inspection technology monitors all production stages at production speed, so you can react quickly. This stabilizes your production.

- 0defect strategy

- 100%process stability

Inspect Inline – Evaluate Online

The VINSPEC inspection system documents and saves all inspection results. A heat map shows defect accumulations; even information from other sources is taken into account. From this cumulative data, you can implement direct and lasting process optimizations. This enables you to reduce costs at every stage of the value chain and increase availability of your system.

Market of the Future

Battery technology for electric cars is a future market. And each process optimization also brings you one step closer to sustainability. Reduce waste, save energy, and prevent costly production defects. Continuous quality assurance helps you achieve greater customer satisfaction and benefit from lasting customer relationships.

We've Been Finding Solutions Since 1995

Our systems have been successfully used by leading OEMs and tier 1 suppliers across the globe since 1995. In battery production, increasing numbers of battery cell and module manufacturers rely on our solutions.