Smart LogisticsOptimized Processes Made Possible by Robotics and AI

In logistics, greater optimization potential is waiting to be used

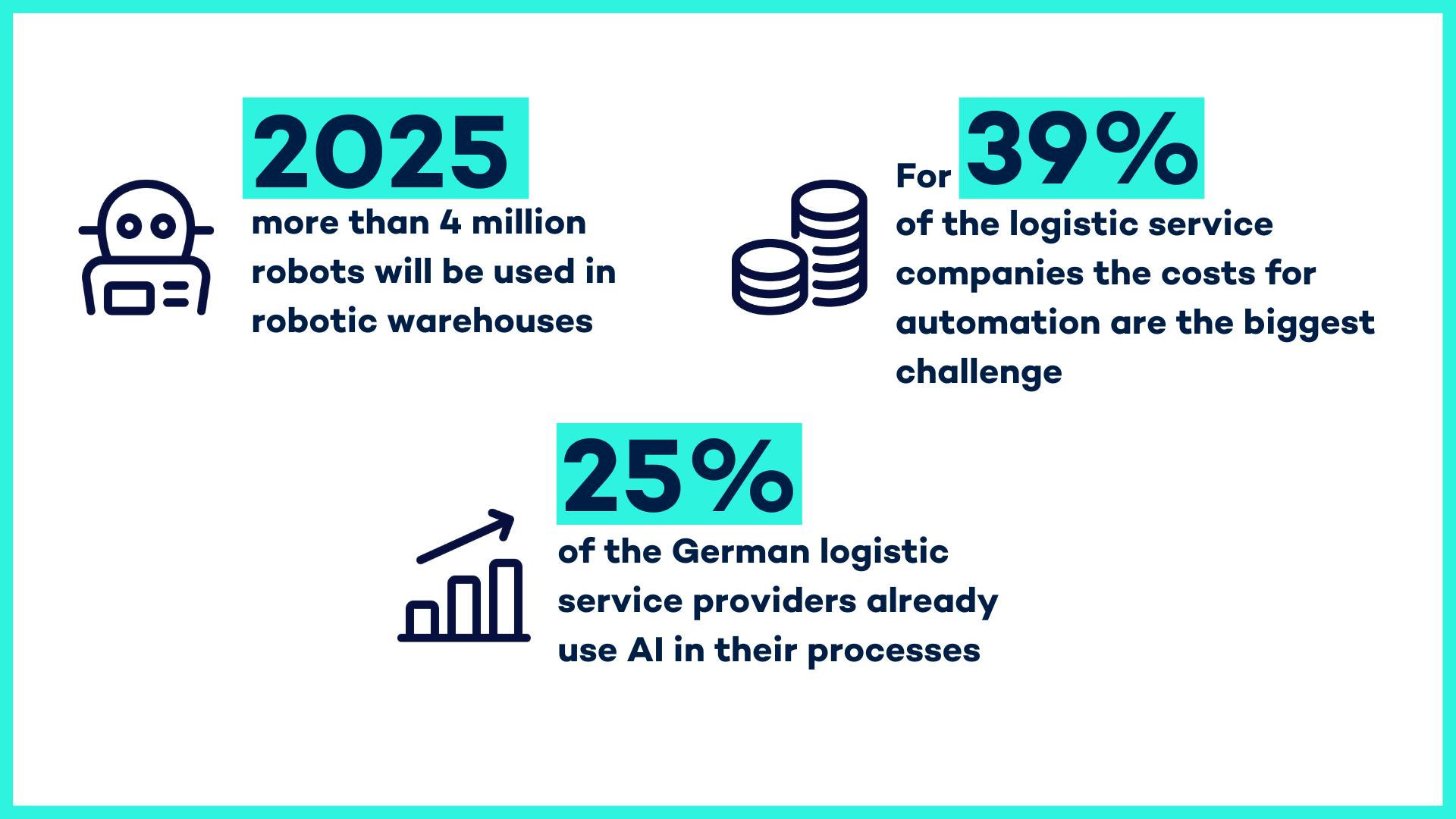

Current estimates assume that by 2025 more than four million robots will be used in so-called robotic warehouses. This article explores what added-value robotics and AI have in store for improving processes in logistics and the requirements needed for successful implementation.

The biggest challenge: costs

The costs for automation technology have been a major obstacle to their integration. In a 2019 survey of supply chain professionals, 39 percent cited cost as the number one challenge. However, 32 percent of respondents indicated that they are already using robotics and another 51 percent expect to use it within the next two years. Rising wage costs will also mean that start-ups and small companies will also tend to rely on automation.

What does process improvement in logistics entail?

Automation will increase the speed for sorting and handling parcels, without compromising on accuracy or security. The latter means that the robots do not injure people and also work stably regardless of the circumstances of their use. The overarching goal of this automation is to make processes simpler and more efficient for logistics companies. Above all, this means only automating tasks can really benefit from robotics and AI.

Integrating robots to speed up an existing process without considering the upstream or downstream process is not very effective. However, robotics can secure important processes as it reduces the risk of errors.

Process optimization is an ongoing topic

Some of the applications that contribute to process improvement in logistics are already established in parcel centers and fulfillment centers. Conveyor belts, sorting systems and Autonomous Transport Systems (ATS) are just a few examples that can either replace or accompany human work. Automated Guided Vehicles – AGVs – for example, can increase the flow of goods after the sorting process. In addition, they can use data to determine whether a package needs to be stored or further processed by the distributor. Ultimately, the next generation of process innovation is about making people and technology work together in smarter ways.

Why should you strive for process improvements?

The advantages of process optimization in logistics are manifold and include the following aspects:

Scalability

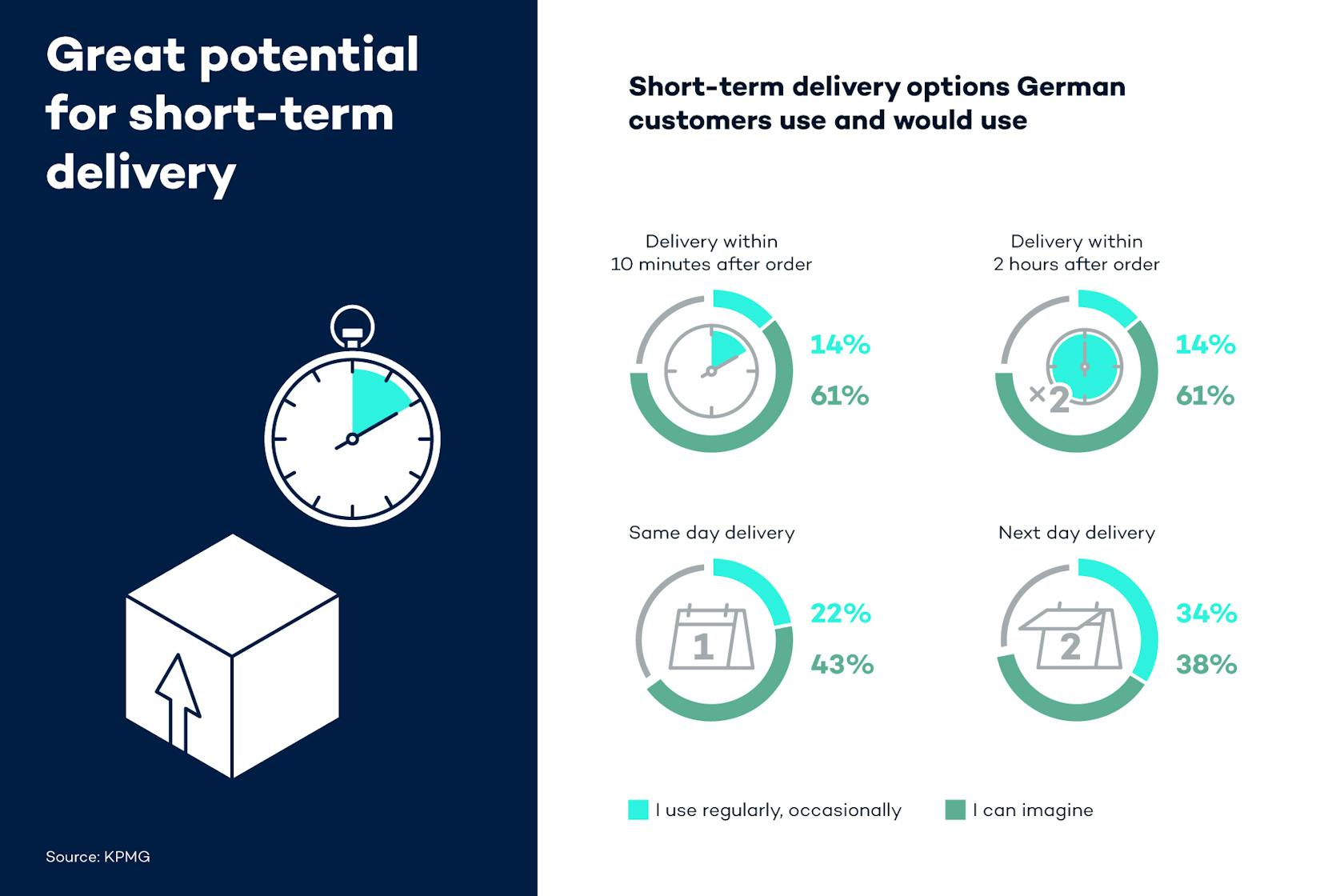

The majority of customers would like their parcels to be delivered in just one to three days. Amazon, Zalando and other companies are already doing this – other logistics service providers are therefore required to keep up. In this context, AI and robotics can help companies scale their deliveries. Load peaks can be cushioned efficiently and capacities expanded comparatively easily.

Tracking & Tracing

Customers are usually very curious about the status of their packages. The more data logistics companies can access, the more information they can use to improve their processes. Humans simply lack the data collection and analysis capabilities offered by robotics.

Green Logistics

Improved logistics, coupled with the use of robots, especially at central distribution hubs, can save storage space and energy when handling packages. By reducing labor and energy costs per package, businesses can process more packages in a single hub.

So, when does it make sense to use robotics and AI in logistics?

Considering when to improve processes is an important decision for any company.

Logistics managers may be wondering whether:

- Their technological maturity must have reached a certain level before they take the step.

- That AI and robotics are compatible with the company's current technological infrastructure.

- They need to grow as a business before they can use robotics and AI.

The truth is that companies of all sizes can, within reason, incorporate robotics and AI into their processes. In fact, process improvement is often much easier to implement for smaller companies—or at least for companies that don't have a concrete logistics or supply chain process in place yet. However, startups and smaller companies usually do not yet have the investments and the volume for integration. It is therefore a matter of a very individual cost-benefit analysis.

Replacing a process that previously relied solely on human interaction is more difficult than designing and deploying an entirely new process.

When will automation pay off?

Logistics companies can early on feel the benefits of their automation investments. This is despite the fact that specific results may depend on factors such as the following:

- labor costs

- energy costs

- number of packages delivered in a certain period of time

There is no magic recipe for automation. Nevertheless, if companies decide to do so, it will not necessarily take long to implement. A simple plug-and-play approach can be developed and implemented in as little as a few months. More individual processes can also be implemented over just a few years.

What will the future of process improvement bring?

Logistics processes are currently being automated very slowly. Robotics and AI are more prevalent than ever, but they're not the norm just yet.

However, using AI and data more effectively for automating processes that were once human-related, will be mainstream in a few years. 5G and Distributed Ledger Technologies (DLT), i.e. digital systems for recording transactions of individual assets, will also gain importance and help to check and track global shipments. These approaches will play a more supportive role for the time being and for now are unlikely to play a key role in improving processes.

From a legal point of view, innovation must also comply with the Sustainable Supply Chain Act, now and in the future. This may mean that logistics companies will be forced to optimize their infrastructure regardless of their personal automation needs or goals in an effort to mitigate their corporate liability.

How can VITRONIC contribute to process optimization?

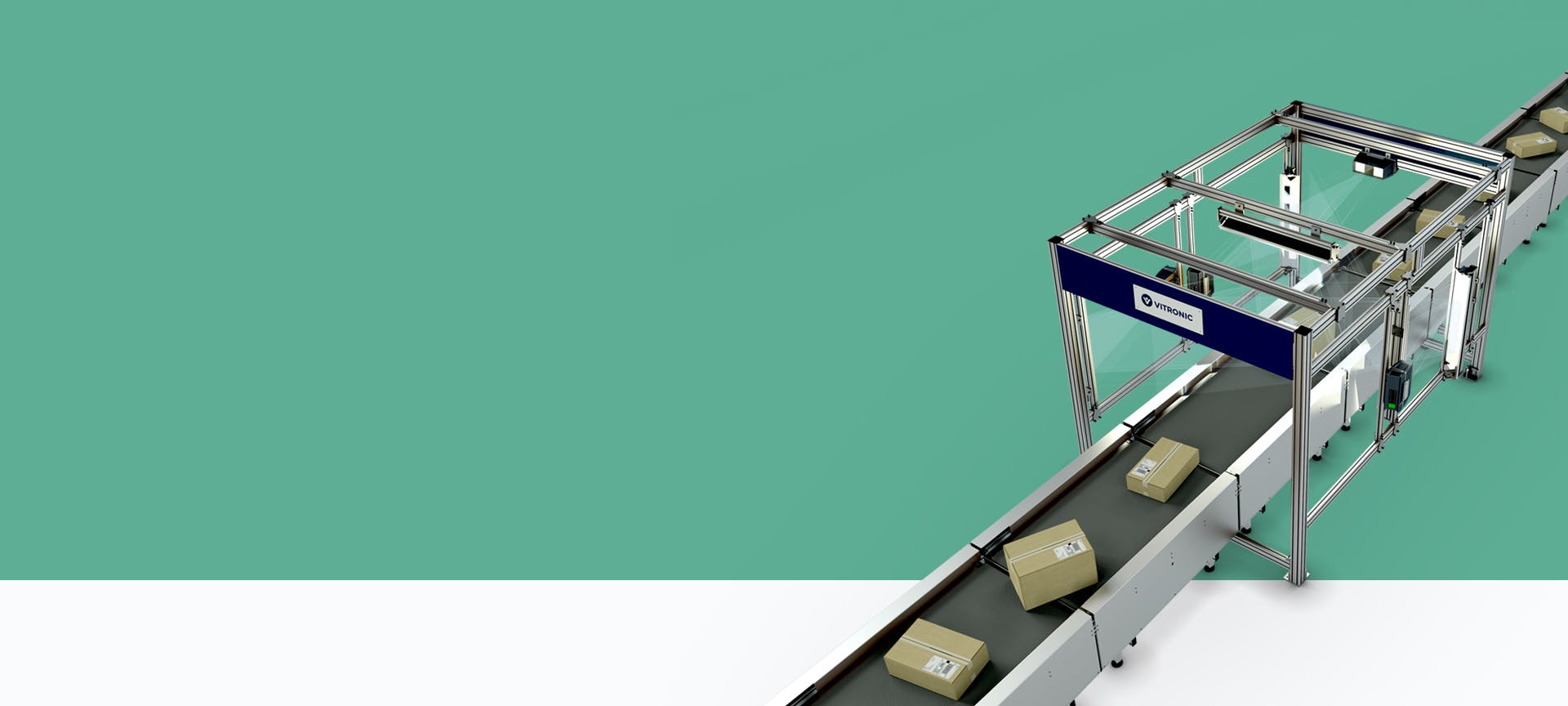

The basis for the optimization of logistical processes is always the automated collection of data - fast, efficient and error-free. VITRONIC offers solutions for the areas of warehousing, distribution and e-commerce logistics, the CEP sector and air freight. This includes systems for recording shipment data such as codes, plain text, weight and dimensions. From the automated support of manual sorting processes to fully integrated reading and sorting systems, VITRONIC offers solutions for every need.

Summary

In Short

- AI and robotics help to make logistics processes more efficient.

- Companies of all sizes can benefit from their use.

- For meaningful integration, the upstream and downstream processes must also be considered.

- In ten years, the use of AI to automate once human-related processes will be standard