Surface Inspection in Fuel Cell Production Hydrogen is the Future

High Quality in the Mass Production of Fuel Cells

Surface Inspection in Fuel Cell Production

Expand Market Opportunities—Ensure Quality

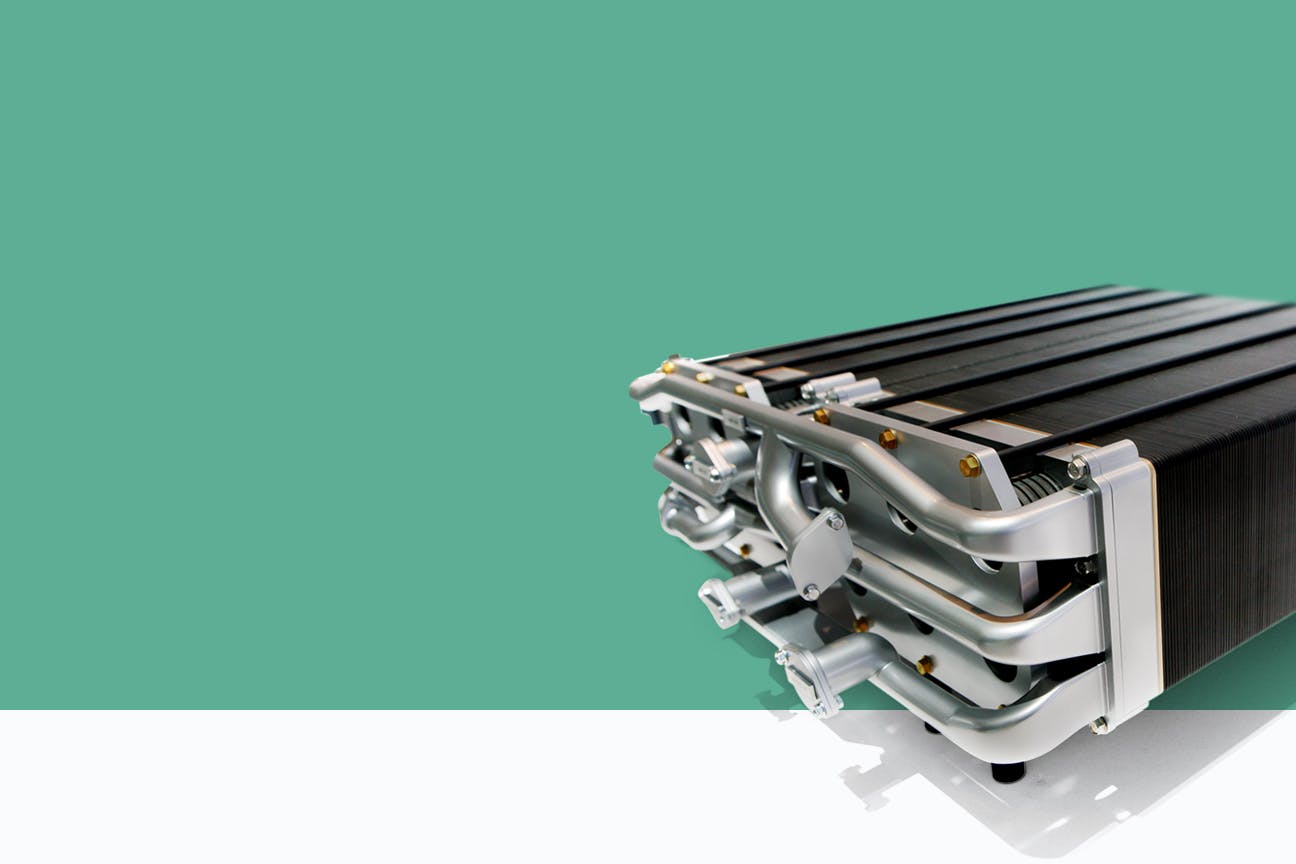

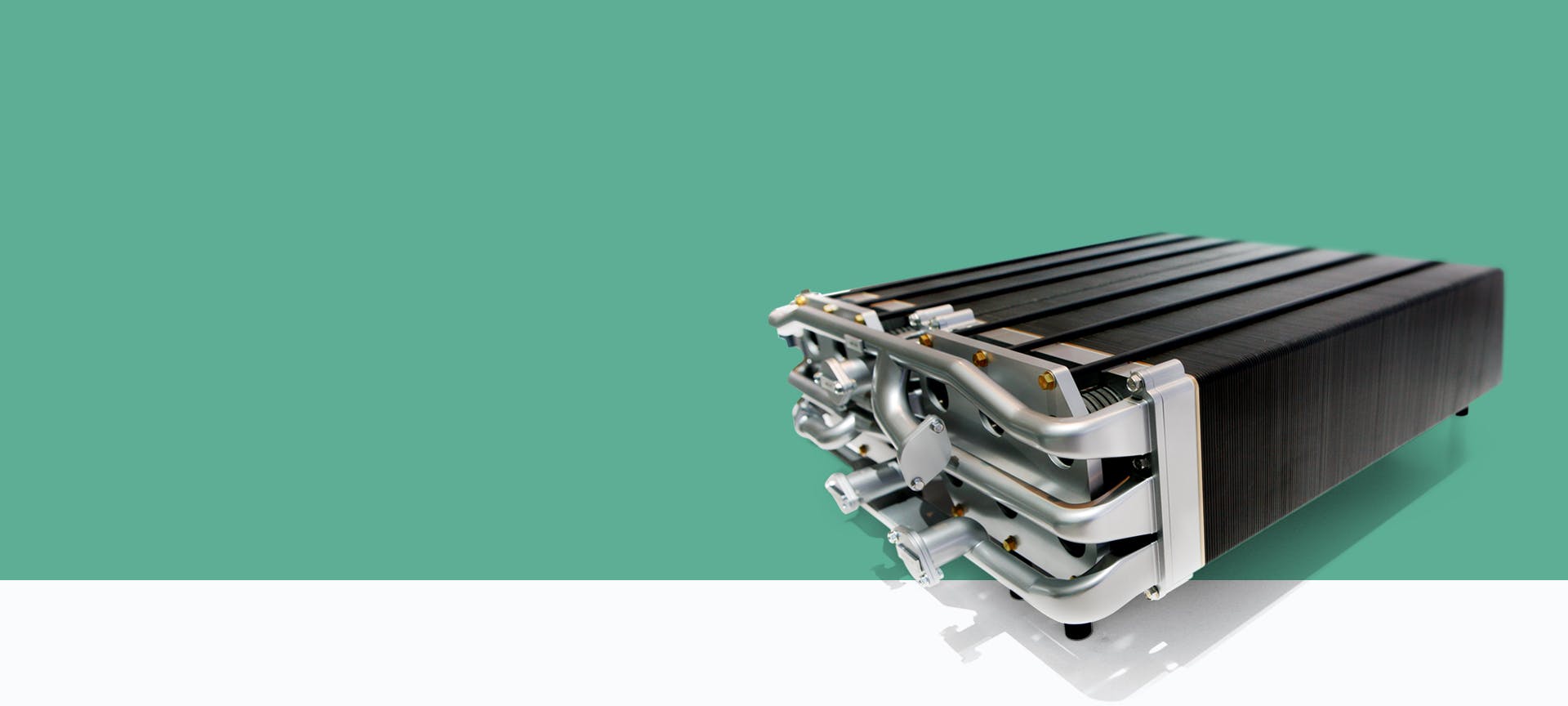

The transport revolution is here. Alongside electric cars, vehicles powered by fuel cells will soon be taking over our roads—producing steam as their only emission. For the automotive industry, fuel cell technology means moving to new, challenging markets. If you want to assert yourself in the market, your quality standards must set you apart from competitors right from the get-go. We’ll show you how inline inspection can support your production of fuel cell components and stacks.

Challenges in Production

No doubt you still have considerable challenges to overcome pending mass production—such as collaborating with new suppliers, handling new materials, or understanding new processes.

To achieve market success, you’ll need to reduce costs, automate production for large quantities, and meet the rigorous performance requirements.

Inline inspection ensures the quality and efficiency of your fuel cells. As a result, only powerful, flawless stacks will leave your production lines.

A Partner for Automotive Manufacturers

We’ve been supporting the automotive industry since 1995. Our systems are widely used in manufacturing. They ensure the quality of powertrains and car bodies and of batteries produced for e-mobility. In fuel cell production, we can also support you with our extensive expertise. We offer far-reaching knowledge of new drive technologies—plus our boundless enthusiasm!

Inspection Systems You Can Rely On

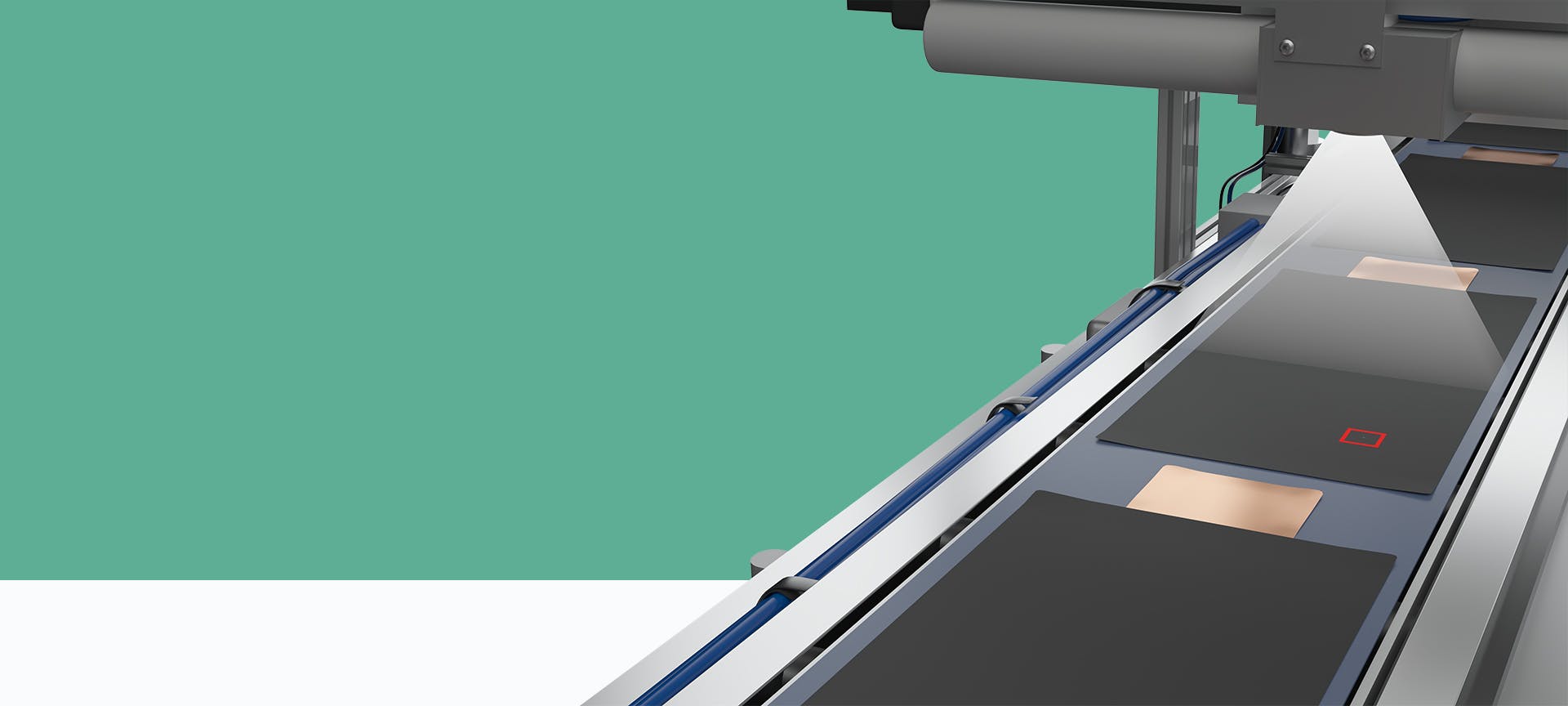

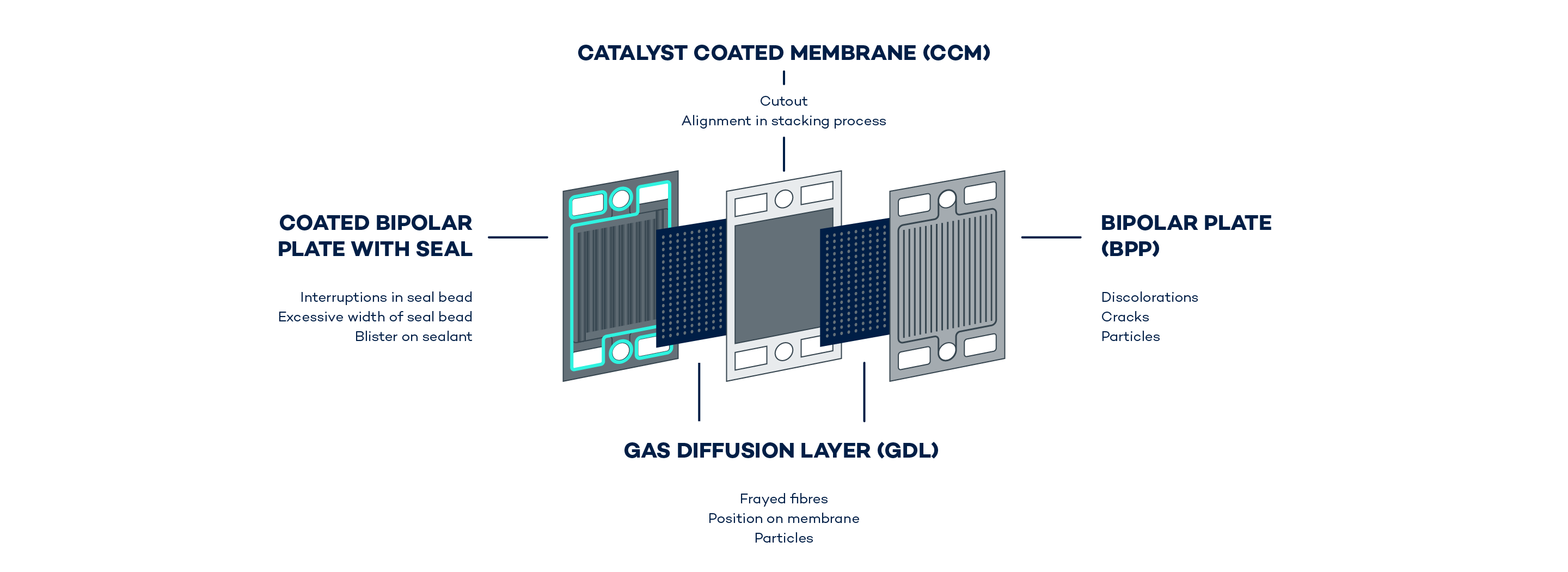

Our systems automatically detect all surface defects in bipolar plates (BPP), membrane electrode assemblies (MEA), and gas diffusion layers (GDL). The systems inspect the components before or during their assembly into a stack.

Of course, you can also use them for inbound or outbound inspection. They reliably detect even the smallest defects—at full production speed. That’s something you can rely on.

- 0%slippage

- < 1scycle time

All Surfaces, All Defects

Even the smallest deviations impact quality and, in turn, the profitability, safety, and sustainability of your fuel cell production. Our VINSPEC systems monitor all relevant quality criteria with automatic, objective, and reliable inspection.

Optimize Processes

As you know, each manufacturing step has its challenges—and the potential for optimization. The VINSPEC inspection system documents and saves all inspection results. Based on this data, you can implement direct and lasting process optimizations.

This will enable you to achieve your goal of reducing costs at each stage of the value chain and producing increasingly high-quality stacks.