ケーススタディAutomated Weld Seam Inspection on Battery Frames

100% quality assurance in e-mobility production

Summary

- Optimization of quality assurance

- Economic and time efficiency

- Reduction of human errors

- Increased safety in the workplace

About the Customer

Wasiak Group, headquartered in Hannover, Germany, is a Tier 1 supplier to the automotive and medical technology industries. Over 300 employees serve more than 65 customers in eight countries. At the Brodnica site in Poland, Wasiak S. A. produces sheet metal parts and complete pressed and welded assemblies for the automotive industry.

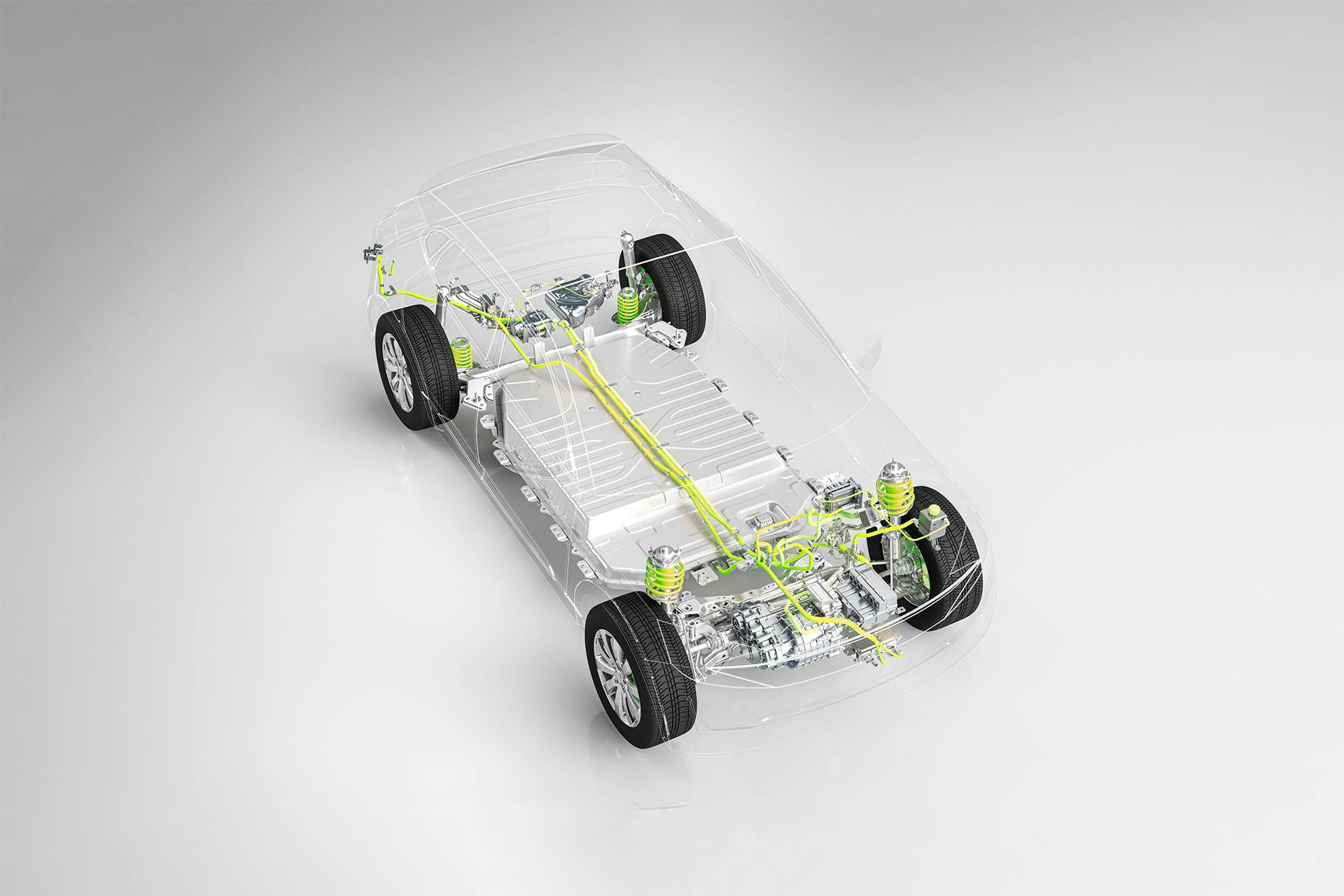

The customer expects 100 percent defect-free parts: The frame for the battery housing must be absolutely stable; it protects the battery in the event of impact and prevents it from igniting. Dirt could also get inside via faulty seams.

Manual inspection of all welds is practically impossible at high production volumes; errors would be inevitable. It would also be too slow and too cumbersome: The heavy frame has to be rotated several times for inspection - a heavy load for humans. The customer therefore demanded an automated quality inspection system.

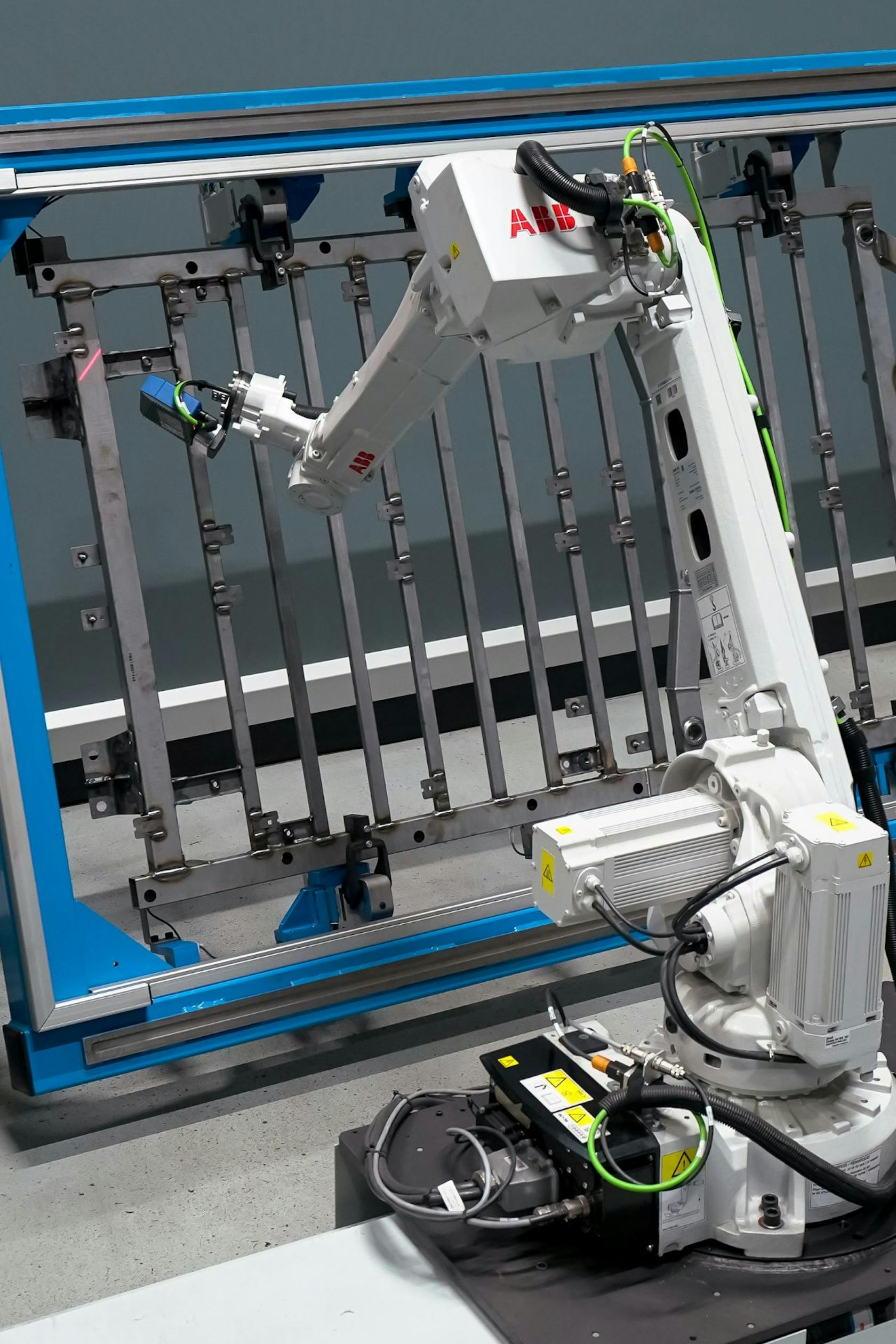

The solution

The individual parts of the battery frame are welded together fully automatically by robots. Directly in the welding line, the VIRO WSI weld seam inspection system from VITRONIC scans all weld seams of a finished battery frame with a movable laser head. In the inspection station, a frame is rotated successively in four positions so that the scanner can reach all seams.

VIRO WSI detects all welding defects and triggers the signal to reject not-OK (NOK) parts. At a visualization station, the defective parts are reworked manually. A display shows the inspection results of the individual seams on the part for the worker. He can see exactly which of the more than 200 seams need to be reworked. In addition, the worker can enter rework performed into the system and document it together with the inspection results.

Automated inspection is more precise and reliable than manual visual inspection; NOK parts are detected before they are sent to the customer. In addition, many quality features can be inspected at the same time.

Quality Features

- burn-through

- deepening

- deviation of weld location

- missing part or missing weld

- pores

- throught thickness

- weld gap for overlap welds

- weld length

- welding spatter

- weld undercut

- weld width

All inspection results are visualized in different views and displayed in real-time statistics. In addition, they are stored in an internal database with component and seam identifiers. Thus, everything is comprehensively documented and can be evaluated and tracked later.

The employees of Wasiak S.A. were trained on the new system in a training course lasting several days and were supported by VITRONIC technicians as needed during the first months. Since then, they have been able to operate the complete system independently and make all settings. Of course, VITRONIC continues to offer service for the system.

The result

Automated weld inspection met the OEM customer's quality requirements 100 percent without slowing down production.

- 100%of the requirements were met.

VIRO WSI has inspected more than 1,000 parts of the frame for us so far. In many cases, it has detected parts with defects, which could thus be eliminated. We have not received any complaints from the customer since the start of production."

Summary

- Challenge: Wasiak S.A. produces frames for battery housings for an electrically powered van. The vehicle manufacturer demands 100 percent defect-free parts.

- Solution: The more than 200 weld seams are inspected automatically with VITRONIC VIRO WSI; defective seams are thus reliably detected and manually reworked.

- Result: After more than 1,000 parts delivered, there was not a single complaint from the vehicle manufacturer.