Menü

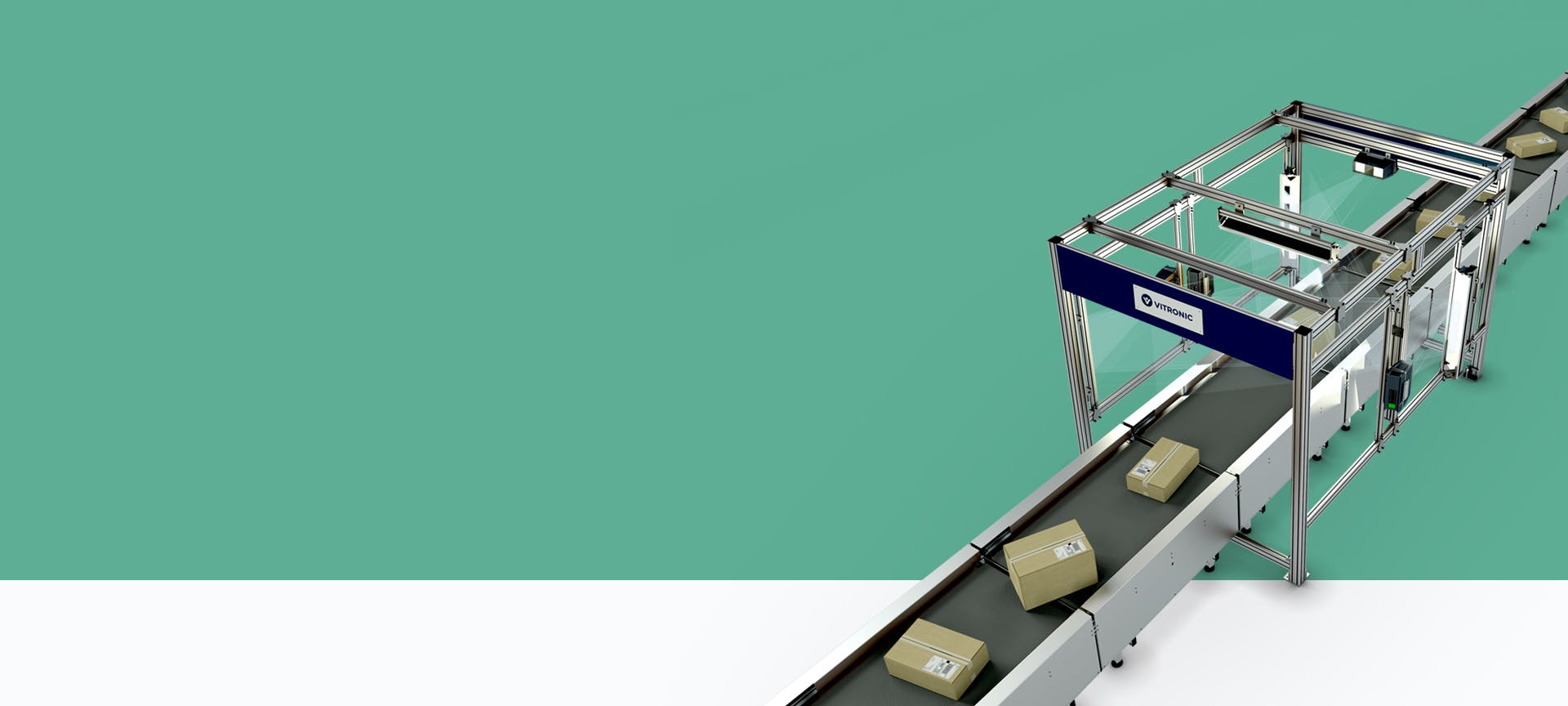

Capturing Incoming Goods Optimize Your Intralogistics

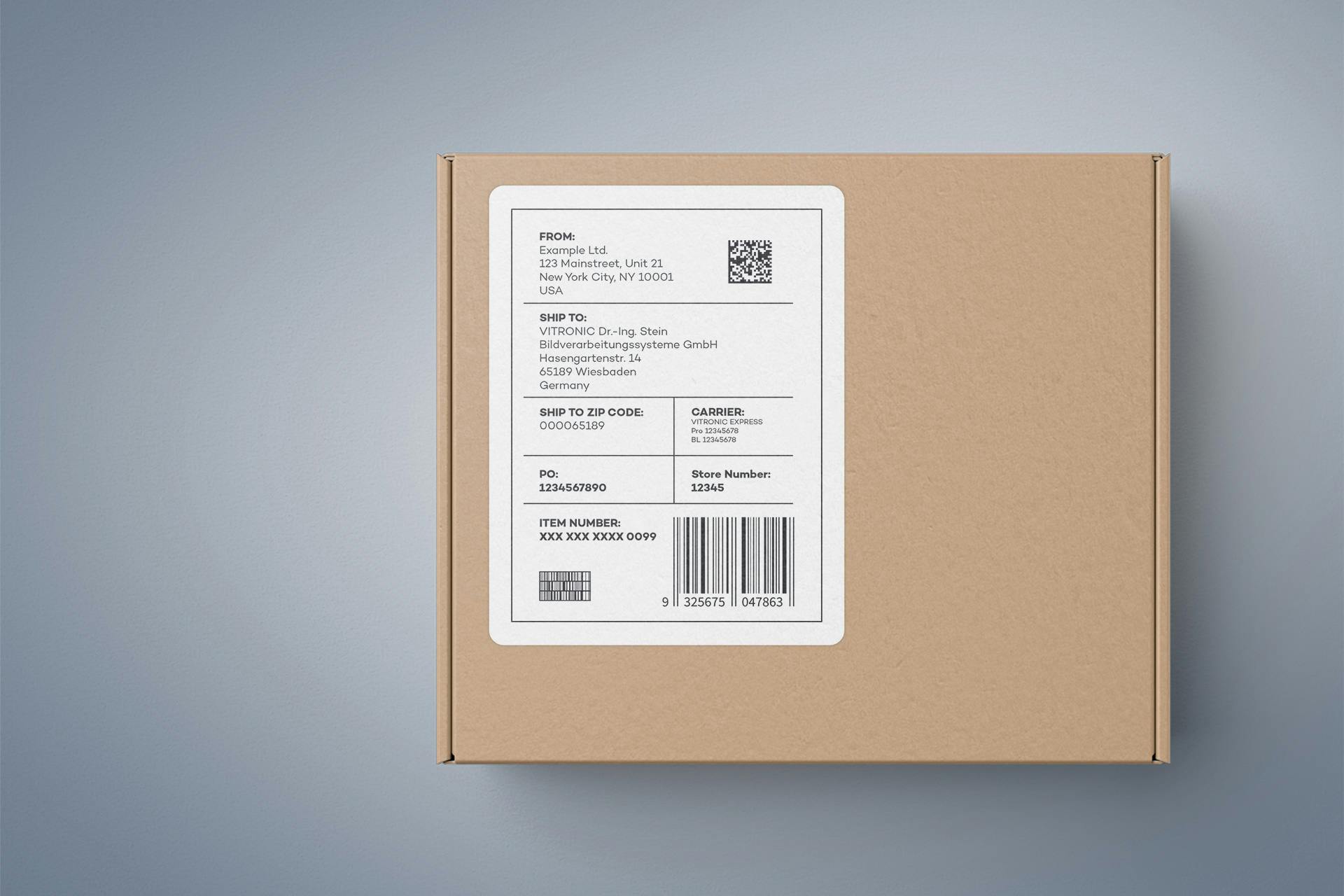

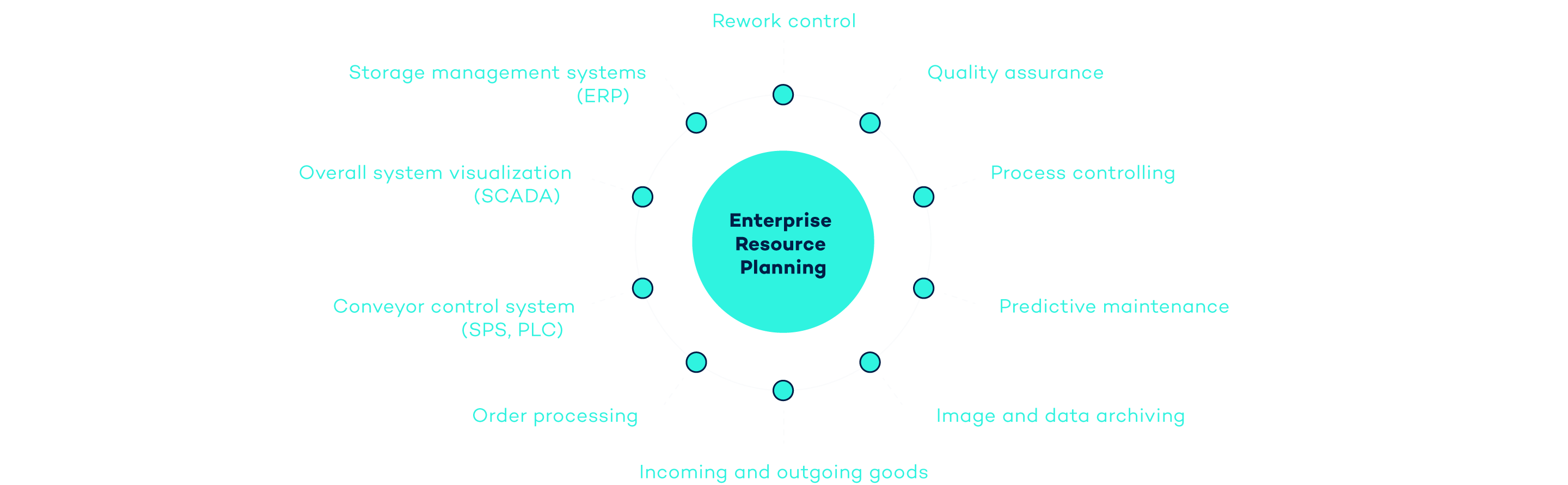

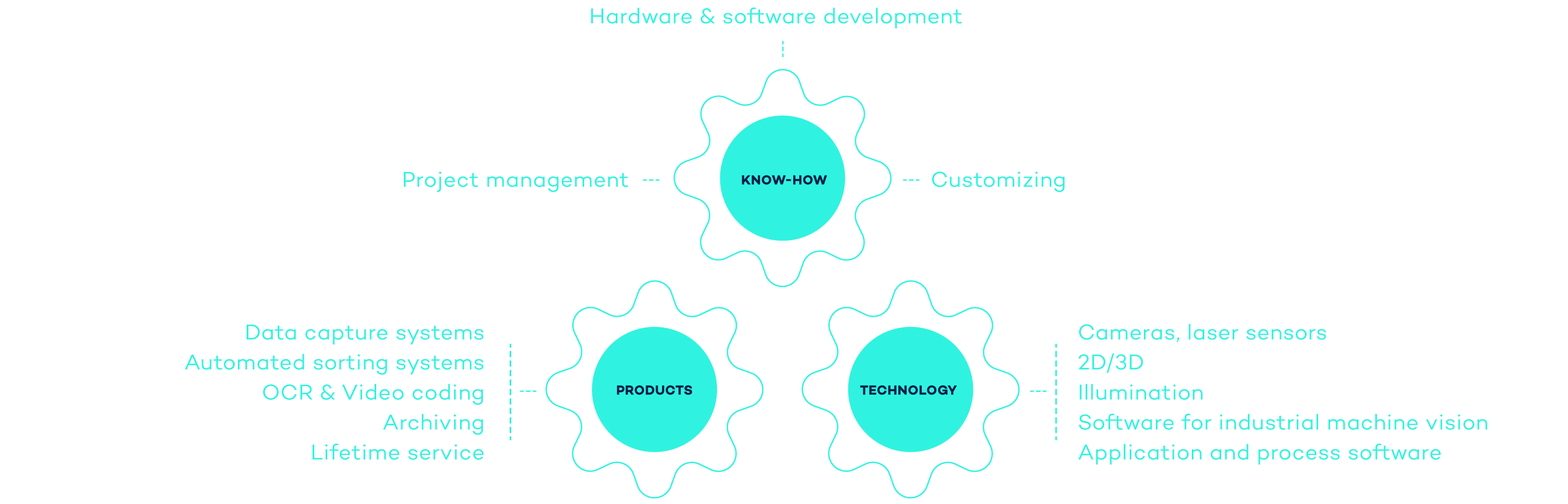

Automated Processes and Data Capture for Incoming Goods

Capturing Incoming Goods

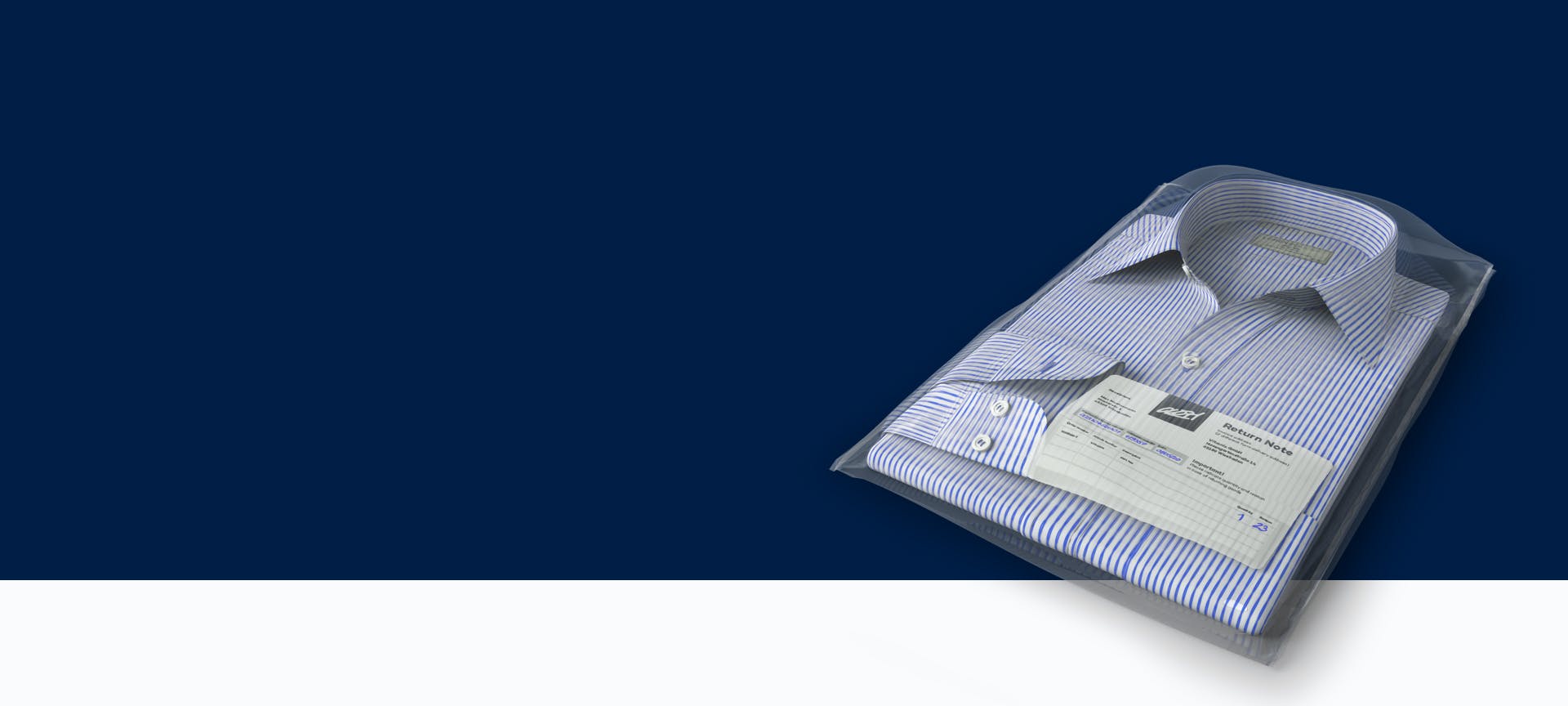

For Taking Away and Passing On

Brochure

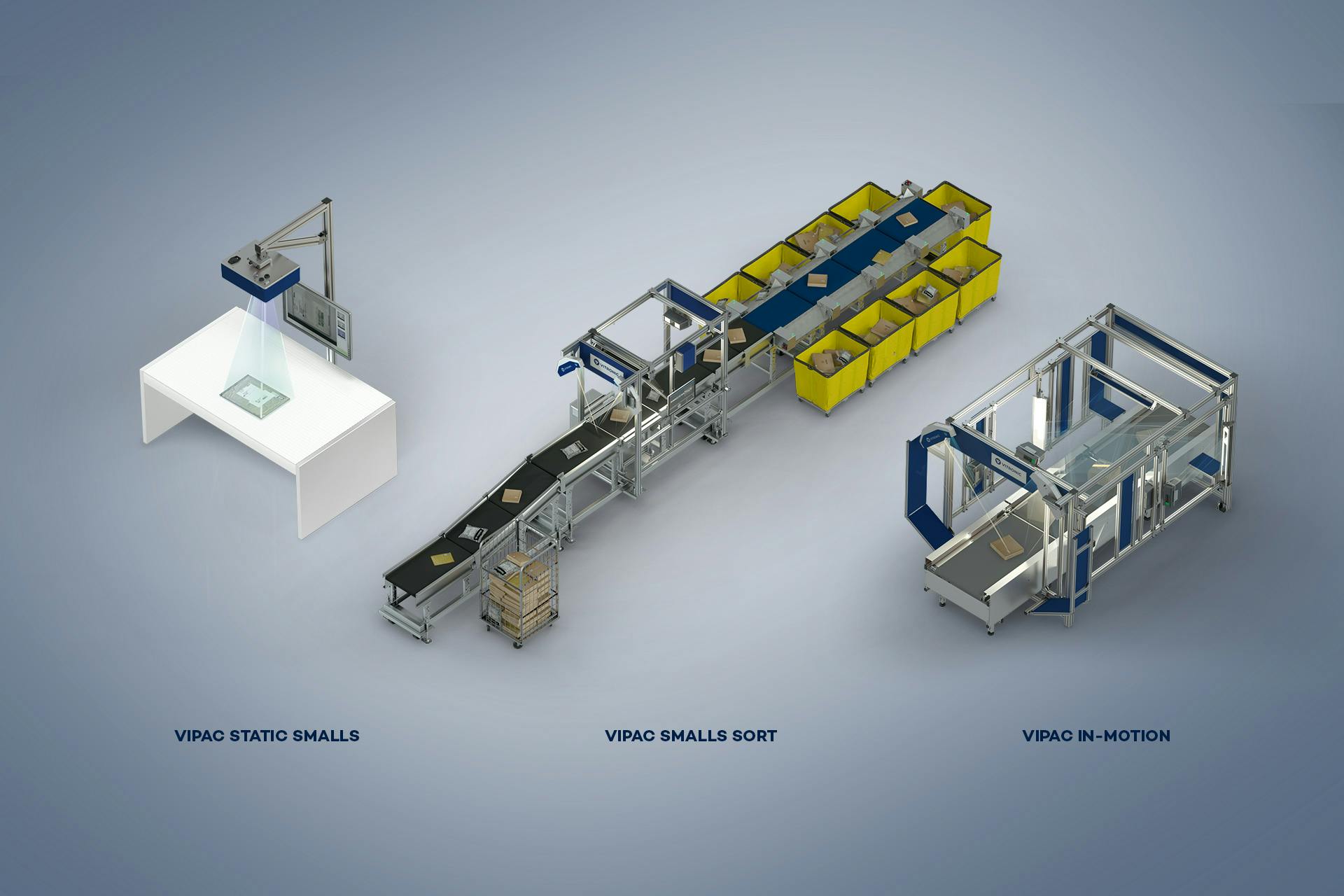

Complete Solution for Data Capture and Sorting of Small Consignments

Brochure

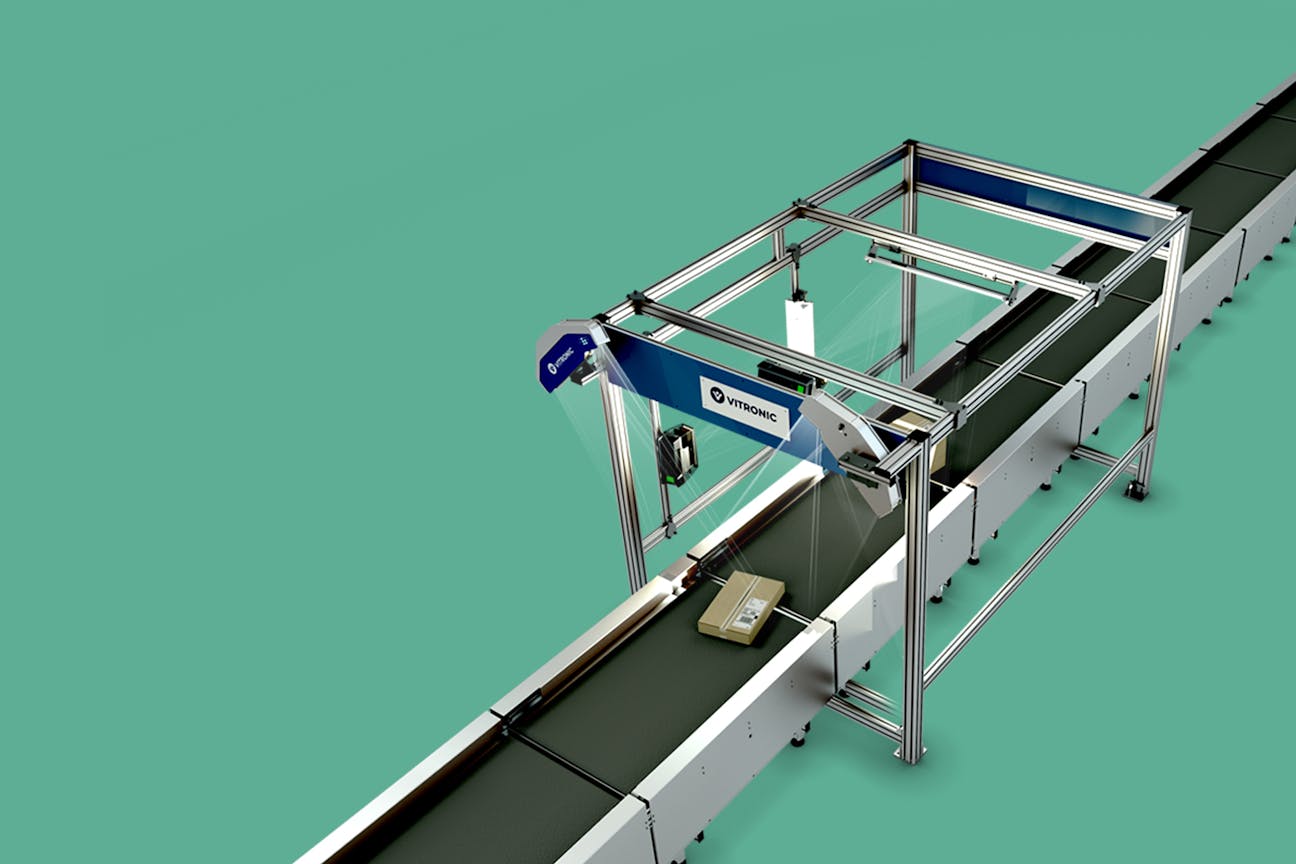

VOLUMEC HD: Dimension Detection With Maximum Accuracy

Brochure

Monitoring, Archiving and Data Analysis for VIPAC Shipment Recording