Smart LogisticsMaking Cross-Border Shipments More Efficient

How Modern Automation Technology Optimizes the International Goods Flows

It is often not possible to process small and medium-sized packages without barcodes and standardized labels automatically. Modern automation technology is key. With intelligent OCR technology and modular sorting systems, it is possible to make international supply chains more efficient.

Rapid Growth in Cross-Border E-commerce

The numbers speak for themselves. With approx. 265 million online shoppers internationally in 2014, we can expect as many as 940 million in 2020. This is an increase of more than 250 percent in just six years.

While international trade welcomes this growth with open arms, cross-border parcel delivery braces itself for a huge challenge. Parcels without barcodes and standardized labels on the conveyor belt are usually sent by standard sorting systems for manual further processing. Increased personnel costs and prolonged delivery times are the consequence.

Challenges Faced by the Postal Service and CEP Services

Postal services and CEP services (courier, express and package service providers) must deal with cross-border shipments, which demand considerably more time and effort to process. Delivery times are prolonged due to the numerous shipments that require manual processing. In some cases, manual sorting has reached its limits, and in a worst-case scenario, the package never arrives at its destination.

A further disadvantage is that tracking shipments in transit from the sorting center to their final destinations becomes considerably more complicated. Without a digital link between the recipient data and the parcel, it is impossible to track the parcel continuously across borders. This is annoying for both the retailer and the recipient.

Cross-border shipment presents major challenges for retailers as well as mail and parcel service providers in the destination country.

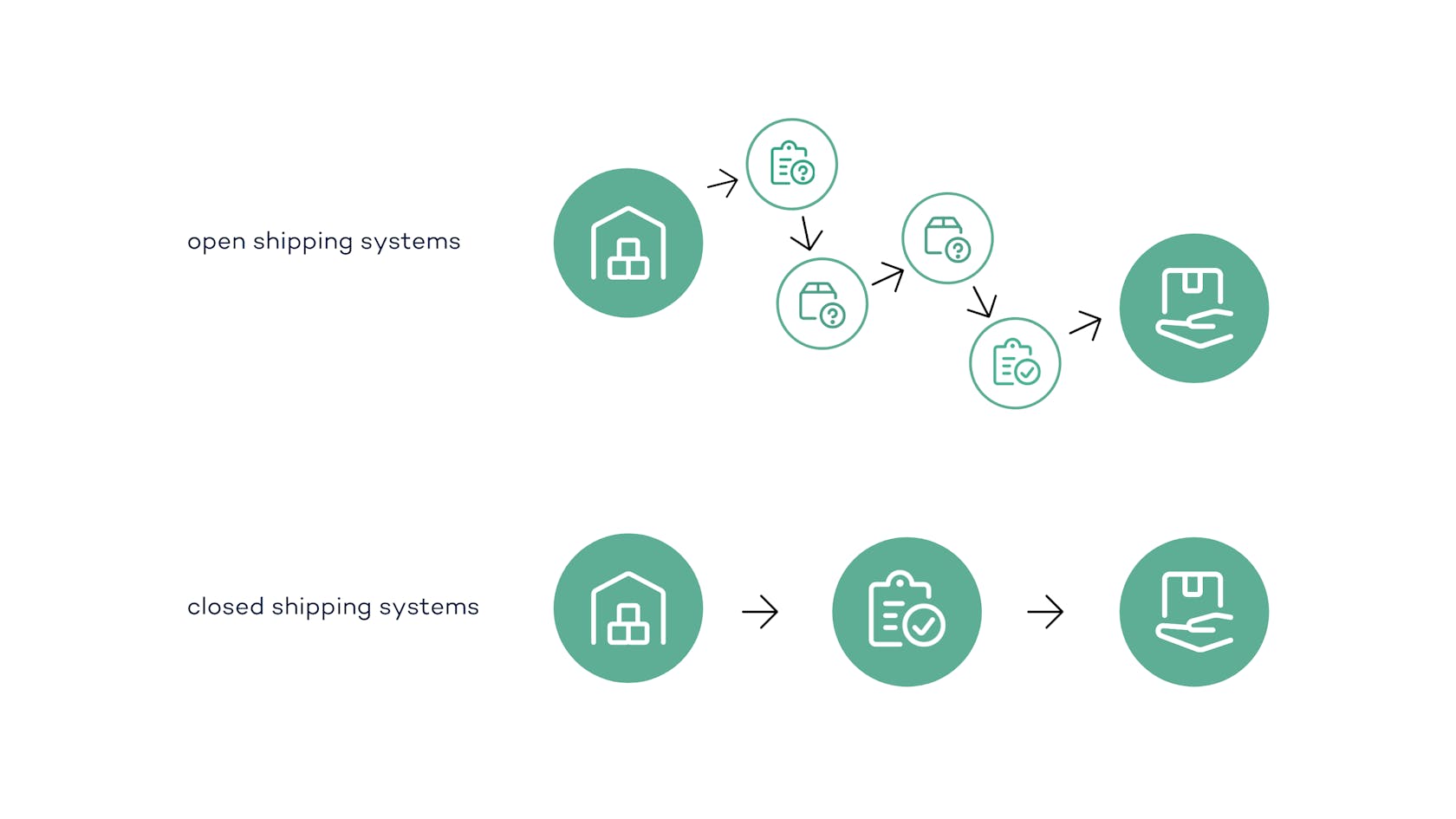

Open or Closed?

The challenges faced by cross-border shipping are closely linked to the type of shipping system used. Typically, open systems are used in international e-commerce goods transport. In these types of systems, the participating package delivery services are independent of one another. This means there are no standardized shipping labels, tracking codes or machine-sortable packaging.

Once packages reach their destination country, postal services in an open system are confronted with numerous challenges:

- No accompanying data or barcodes

- Addresses that are difficult to read—sometimes with foreign characters

- Many single items consisting of letters or small packages

- No ability to track shipments

- No machine-sortable packaging

The disadvantages of open shipping systems are obvious. Sorting systems reach their limits, employees must manually process shipments, costing time and money, and customs clearance makes the entire shipment a loss instead of a profit.

And by the way, even closed systems are not always economical, especially when low-value goods are shipped internationally. While universal service providers such as UPS, DHL, and FedEx are faster and more transparent, a closed system hardly makes a difference in the standard shipping of parcels due to their cost structures.

Automation Is the Bridge Between Country Borders

The key to more efficient shipment handling across borders is the sorting system’s technology. Today, innovative automation technology is, to a great extent, the driver of machine-controlled package handling in sorting centers.

The digitalization of shipment handling focuses on two main tasks: data capture and sorting. Even today, these tasks are cost and time intensive, even though they could be easily automated with the right technology.

High-Performance OCR Technology for Optical Character Recognition

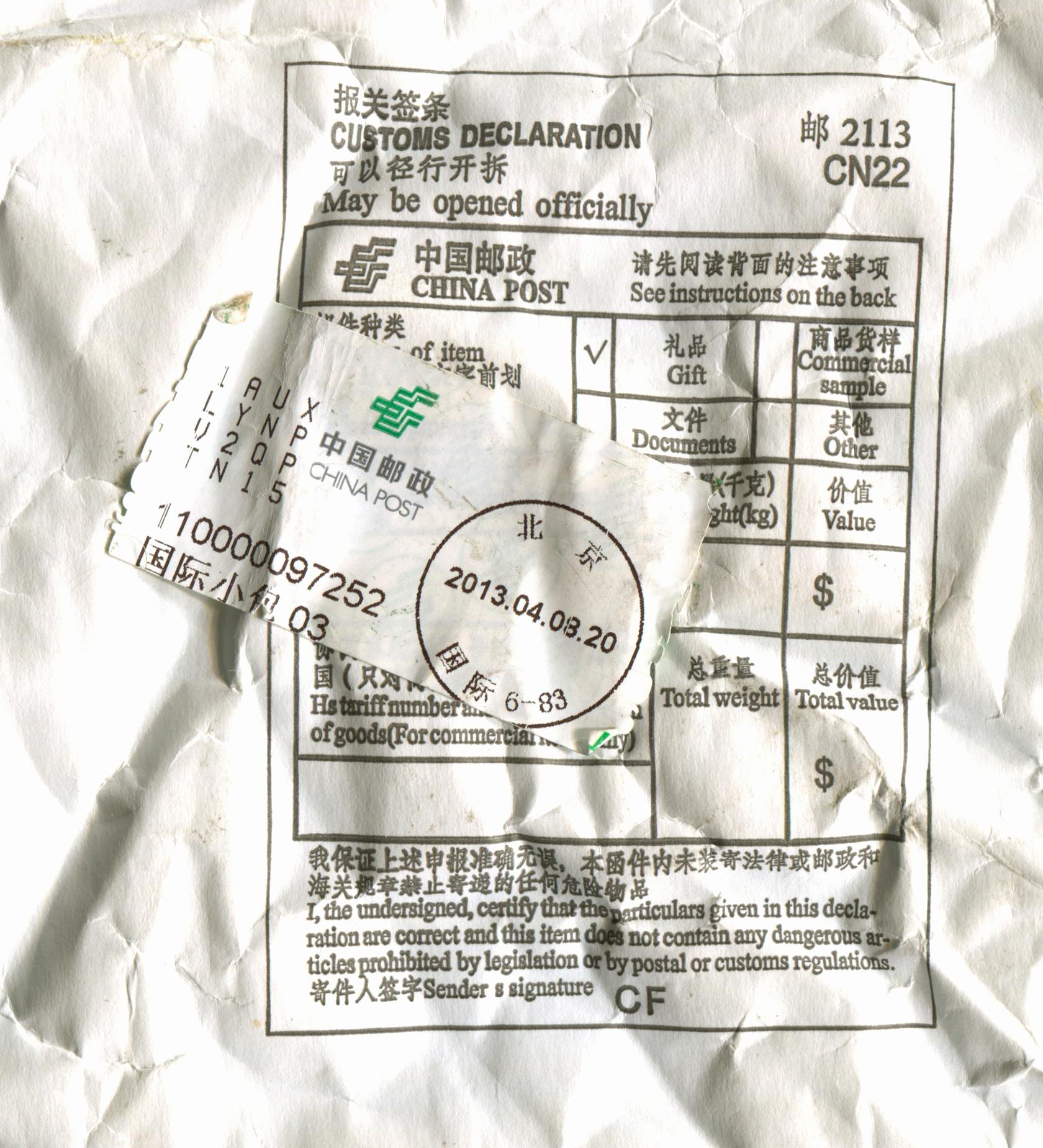

With state-of-the-art optical character recognition (OCR) technology, it is also possible to reliably capture international shipment data without a standardized label. From foreign characters to nearly illegible handwriting—high-performance OCR software can easily handle even today’s most complex reading tasks.

And in the event data capture, despite state-of-the-art technology, doesn’t work, an image of the package is sent to a computer workstation. The system then uses video coding to fill in the missing data, keeping delays to an absolute minimum.

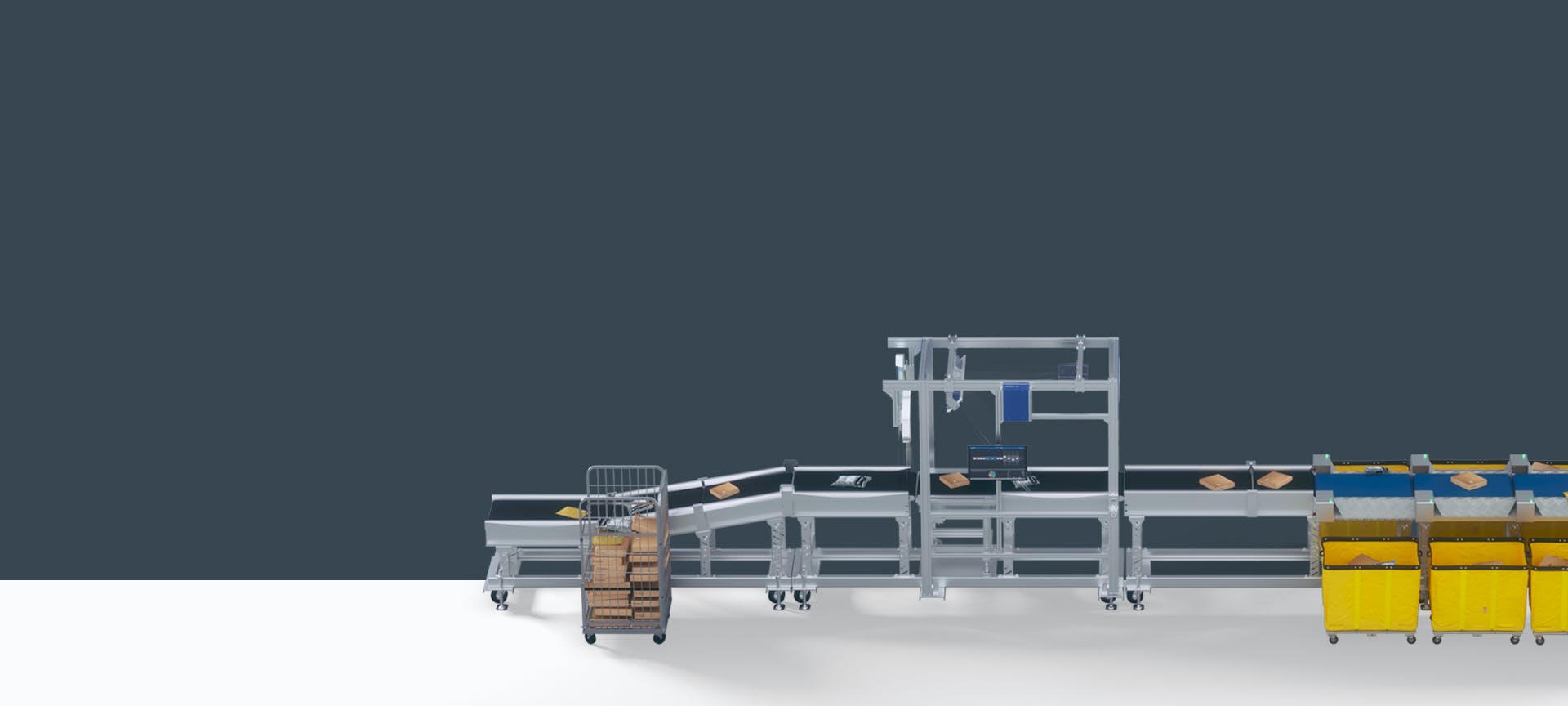

Turnkey Systems for Cross-Border Shipment Requirements

In addition to data capture, automatic sorting of shipments is a challenge in the world of international goods transport. On-site letter and parcel sorting machines are often overwhelmed by unusual shipment shapes and sizes.

Yet today, there are solutions for meeting the requirements of cross-border shipments using modern, turnkey systems. By vastly automating the supply chain, it is possible to make the international flow of goods faster, more transparent, and efficient. Manual tasks can be kept to an acceptable minimum with a turnkey solution.

SUMMARY

Benefit from Automated Cross-Border Shipping

- Cross-border e-commerce is growing rapidly.

- Sorting systems have reached their limits when it comes to international shipments.

- Automated data capture makes supply chains more efficient.