CorporationAutomatic Measurement of Tiny Shipments

A record volume of around 775 million courier, express and parcel shipments were transported by parcel services in Germany in the 2020 Christmas season, according to the German Parcel and Express Logistics Association (BIEK)[1]. Such a volume can only be handled with automated solutions. CEP service providers depend on the precise measurement of the height, width and weight of each shipment: for transparent flows of goods in hubs and reliable invoicing to customers.

Certified capturing of dimensions

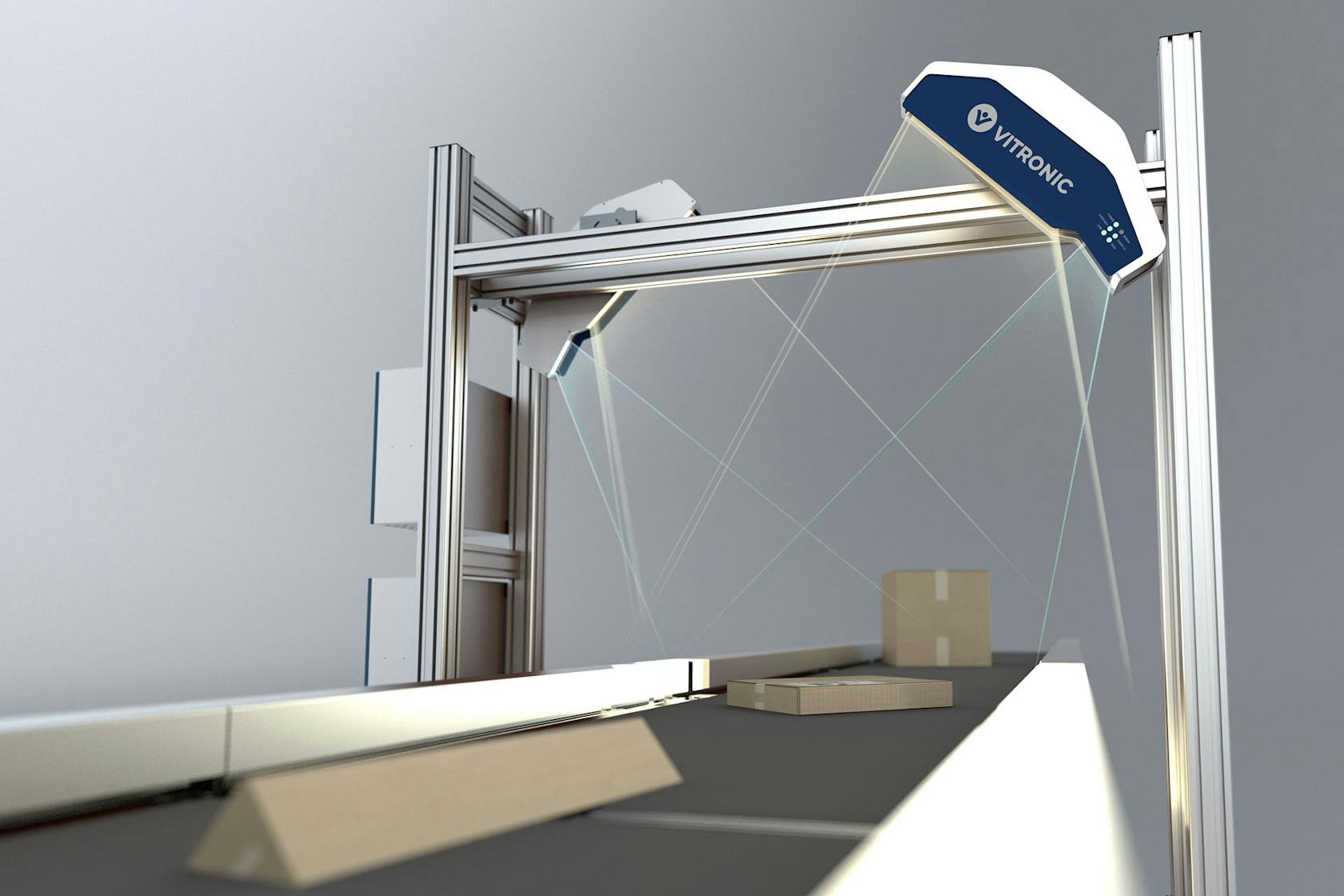

VOLUMEC HD is a core component of the VIPAC IN-MOTION systems for fully automated capturing of shipments, and it automatically measures the dimensions of cubic and non-cubic objects on conveyors and sorters. The VOLUMEC HD 3.0 release features new sensor technology and improved laser technology: the point cloud density has been further enhanced, non-cubic objects are now identified even better. It detects even the tiniest items from 2 cm in height and can also measure the complex hull of an object, such as shipping bags (add-on Convex-Hull-Detection). All captured data is displayed in real-time via a 3D view and, in the case of calibrated systems, is stored securely to prevent tampering.

VOLUMEC HD holds European and international certifications and is approved for automatic invoicing. All data is automatically stored in the archive system and, in the context of Industry 4.0, provides valuable insights to accelerate processes in distribution centers and thereby reduce costs.

Download press release

About VITRONIC

VITRONIC is the world's leading innovation driver for machine vision, enabling its customers to master the challenges of tomorrow.

The global group of companies develops forward-looking solutions in the form of specialized products and software for image-based quality inspection, identification and process optimization, which find application in the growth sectors of automation and traffic engineering.

VITRONIC solutions make an important contribution to helping shape a safe and sustainable world. The existing limits of what is economically feasible are constantly being questioned in order to achieve the highest quality and productivity, for example in the production of automotive and pharmaceutical companies. Worldwide, Auto-ID solutions in logistics centers and at cargo airports, take over the reliable and efficient recording of shipments and thus ensure a transparent flow of goods.

In the transport sector, VITRONIC offers leading technology for increased safety on the roads, for optimizing traffic flow and for recording road usage.

Open and honest dealings with our customers form the foundation for jointly exploiting technological and process potential to the full. Joint success forms the basis of long-term cooperation with companies such as B. Braun, BMW, Daimler, DHL, UPS, Fresenius and Sanofi as well as with public clients.

Since its foundation in 1984, VITRONIC has been growing continuously for 40 years. The current annual turnover (2024) is 260 million EUR and the company is currently represented on five continents in over 80 countries with approximately 1,400 employees. Since 2024 the company is part of ITIS Holding, leveraging the strengths of both entities, creating a strong end-to-end ITS and automation provider.

Development and production of VITRONIC systems are located at the company headquarters in Wiesbaden. VITRONIC subsidiaries span across all continents, including North and South America, Europe, Asia, Africa, and Oceania. Additionally, a global network of sales and service partners ensures localized support for international customers.