Smart LogisticsMore transparency for supply chains

Tracking & Tracing of goods will support companies in complying with the German Supply Chain Due Diligence Act in the future.

Both regulations redefine the responsibility of internationally active companies in the entire supply chain - from raw materials to the finished product. In addition to human rights, the focus is on due diligence along the entire supply chain and the protection of the environment and consumers. Its purpose? Safe, human rights-friendly and CO2-neutral products across all supply and production chains. This is made possible by the so-called Track & Trace of goods.

What is Track & Trace? In this context, "Track" defines the option of being able to determine the exact physical location of a product at any time. "Trace" in turn serves to reproduce and understand the course within the supply chain.

Up to now, Track & Trace has supported, among other things, subsequent tracing, for example in the case of product recalls or hazard notifications. The Supply Chain Due Diligence Act gives Track & Trace further relevance. In addition to the tracking of finished products and product components, data in the production and delivery process is now also recorded and evaluated, which supports the measurement of CO2 emissions. This includes the use of means of transport and also transport routes as well as the energy input per supply chain step.

Companies in the responsibility

Around 900 companies in Germany with more than 3,000 employees (see footnote) must ensure transparency in the supply chain from 2023. From 2024, the regulation will also apply to Germany's SMEs with more than 1,000 employees and thus around 4,800 companies.

Whereas in the past, companies could be held liable for a maximum amount of up to 85 million euros for personal injuries incurred under the Product Liability Act (§ 10 ProdHaftG), violations of the Supply Chain Due Diligence Act could entail even significantly higher penalties and severe damage to the company's image.

Having complete transparency over the entire supply chain is one of the most important aspects in preventing liability cases and violations of the Supply Chain Due Diligence Act.

Supply chain transparency in the EMS industry

The EMS industry (Electronic Manufacturing Services) is already setting the example for successful Track & Trace: Manufacturing service providers for electronic components that produce parts for the automotive industry, for example, are already subject to strict requirements. A globally valid certification according to ISO 9001 to maintain business capability is an absolute must for each of them. Part of the quality management specifications is the traceability of the installed parts - regardless of which service provider supplied them. Previously, the data was used to recall defective component series. These recalls could be reduced from a complete series to one series, one assembly or a few defective units. In the future, the data will also be used to identify violations of the new law.

More data, better decisions

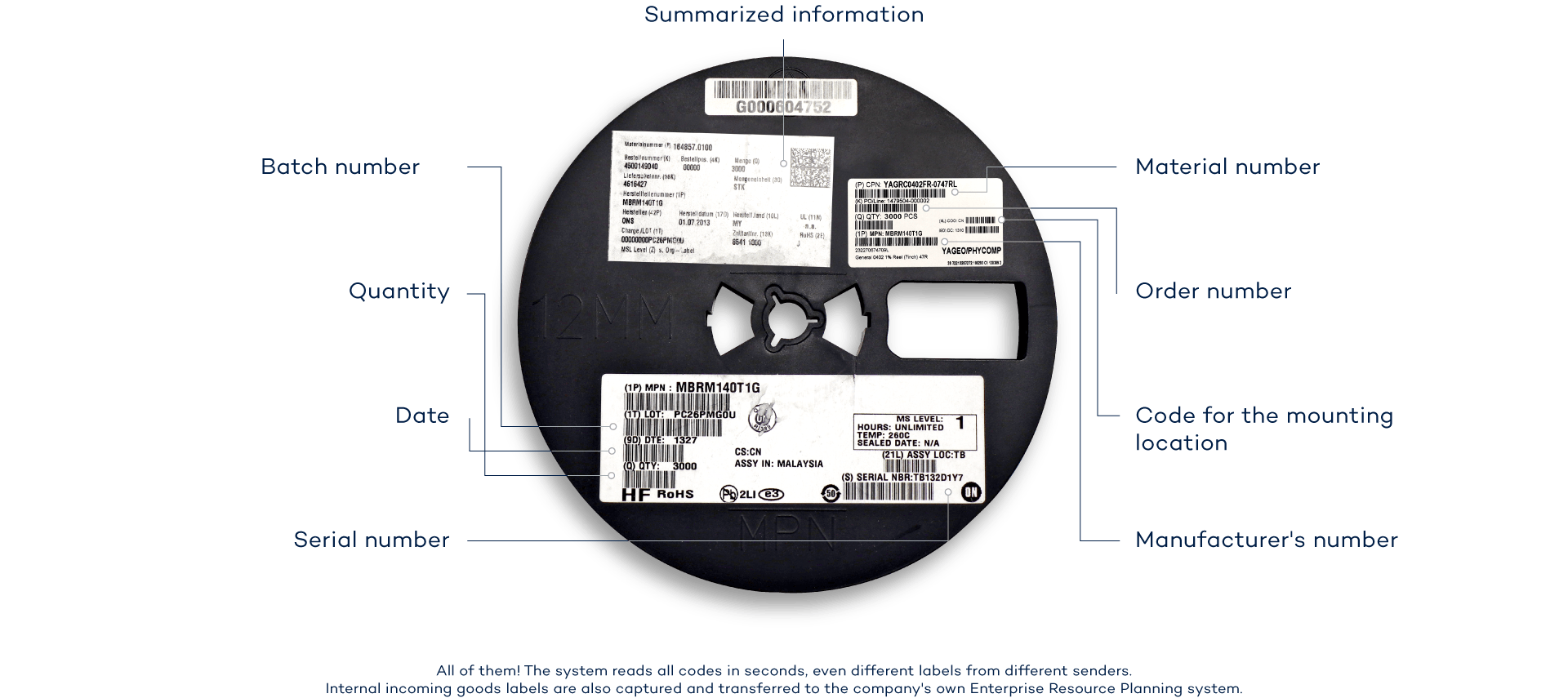

And the better the data quality, the more information is available to the company for analysis purposes. This includes, among other things, data on the producer, information on the exact time of delivery, the current processing location, the time still needed until transfer or other even more detailed information. This can, for example, concern the weight or volume of the goods in order to determine which means of transport had to be used to transfer them. The information is grouped into different meta categories. They include consignor information, destination information, control information and identification information. All these steps are relevant to calculate the concrete carbon footprint.

The new generation of barcodes

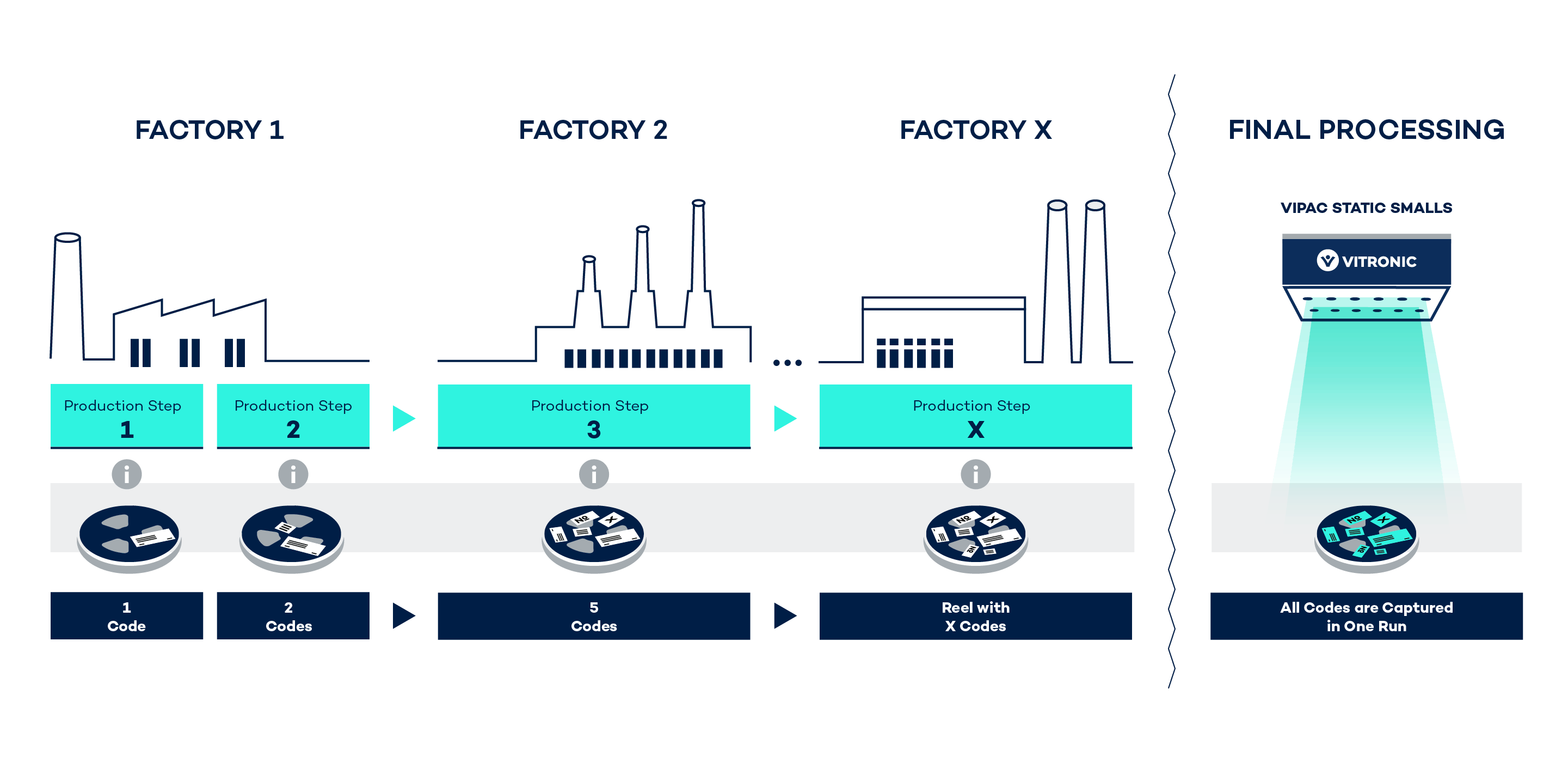

One solution for integrating the information is, for example, to document individual process steps in the supply chain with the help of additional barcodes. In the future, they will document more extensive information than before and must therefore also change - from one-dimensional barcodes to multi-dimensional data storage. If simple codes are used that can record little information, they must be available in very large numbers. This often leads to a high error rate during manual reading. If complex barcodes are used, special hardware is required.

For the amount of information stored, there is an ever-increasing need to balance the size of the codes, their readability and their number. However, more complex barcodes or matrix codes also require correspondingly more powerful readers.

The devices must capture all data at once and be able to read even small, colored, poorly printed or damaged codes without any problems. It is important that all information on an object is automatically captured quickly and reliably in just one pass. The goal is maximum throughput, secure archiving and complete traceability in order to comply with all legal requirements and quickly retrieve the information required by the Supply Chain Due Diligence Act.

Conclusion

In short

- Track & Trace can map complete supply chains

- Transparent data from the entire production and supply chain can be used to determine the CO2 footprint of products and services

- Legal compliance requirements increase

Summary

You can edit this slice directly in your code editor.