Menü

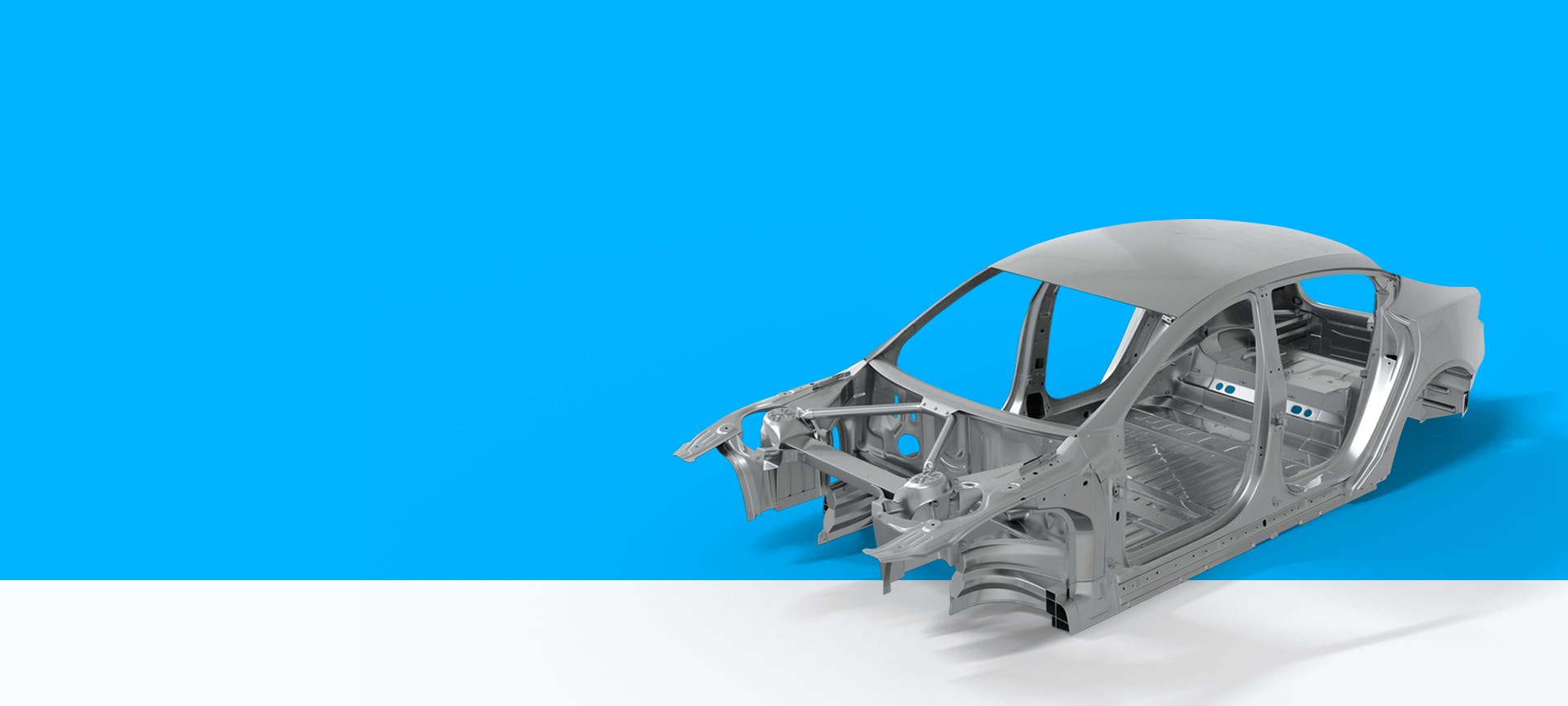

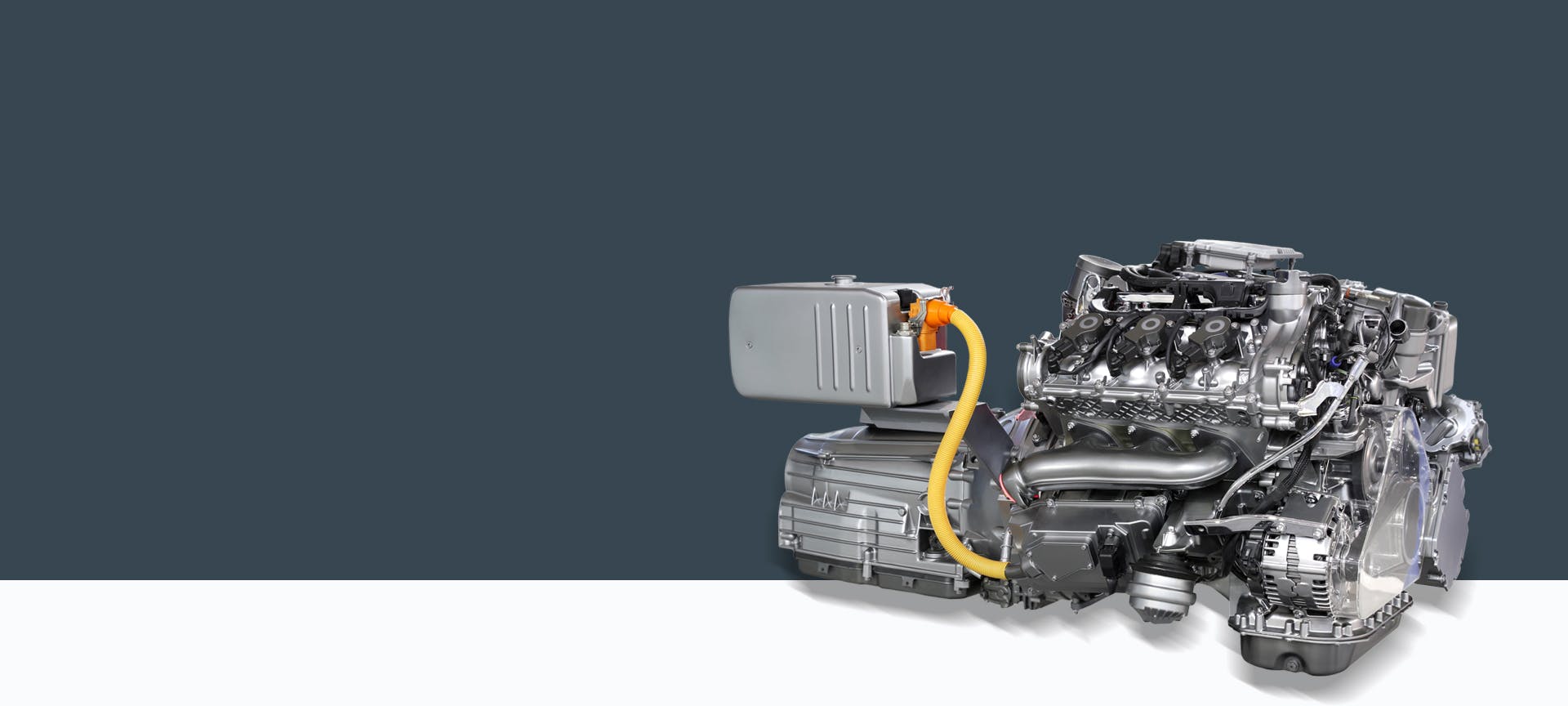

Weld Seam Inspection for Axle Components Safety Instead of Recalls

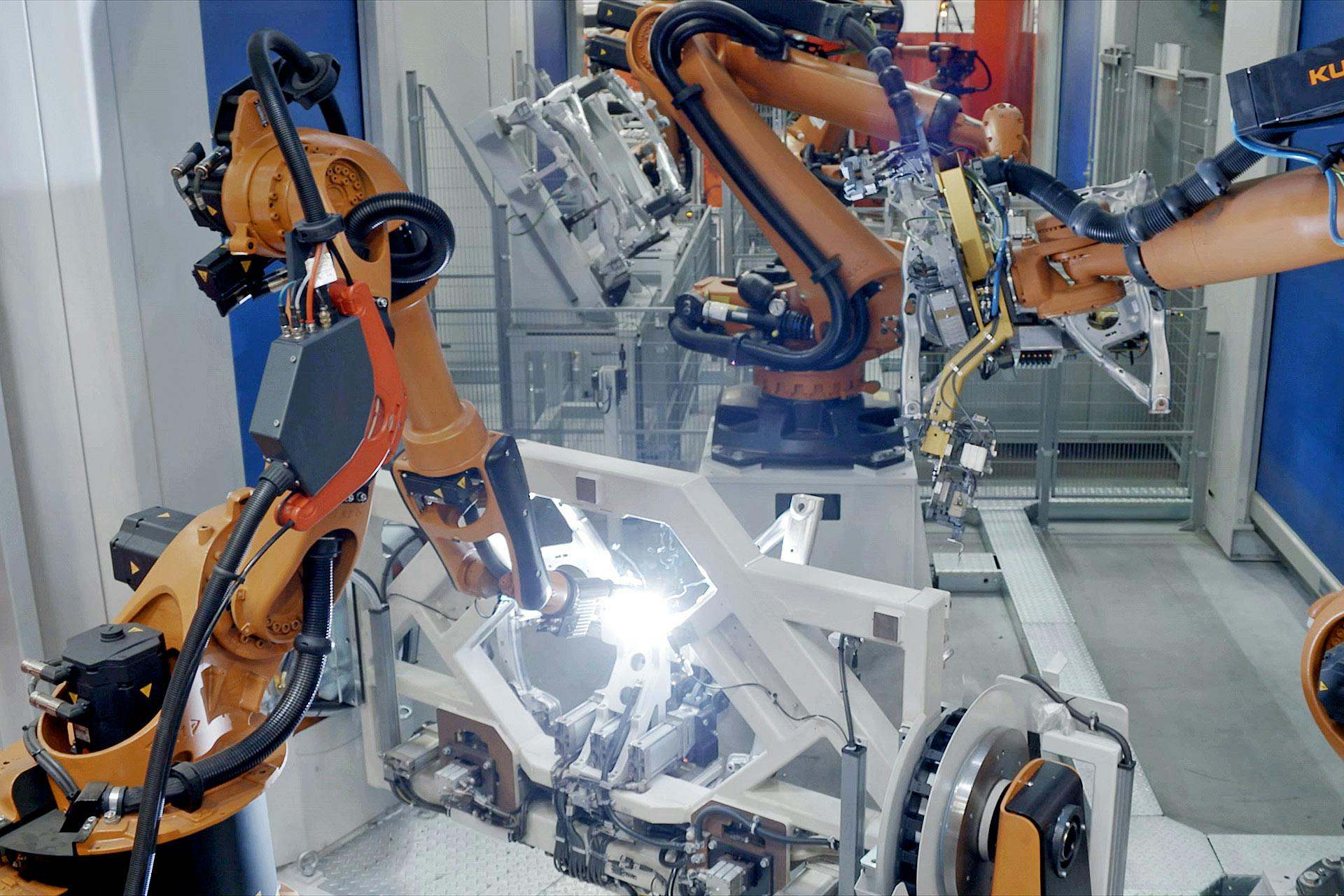

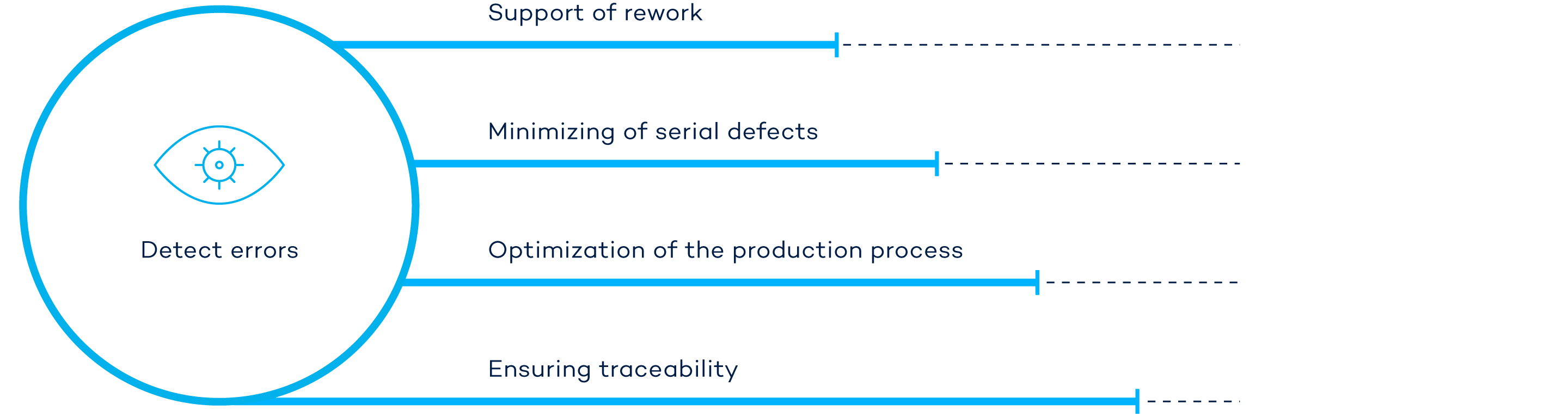

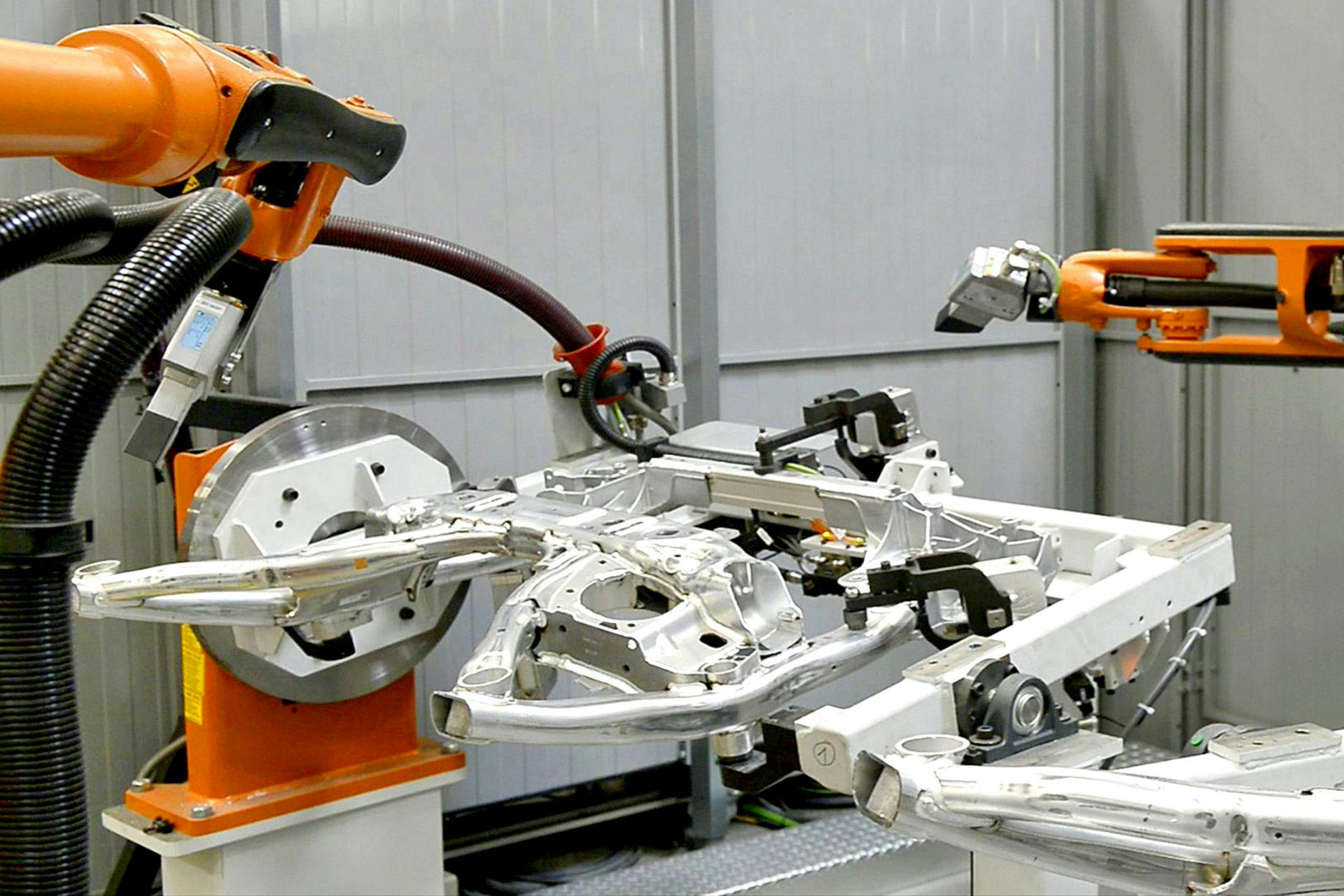

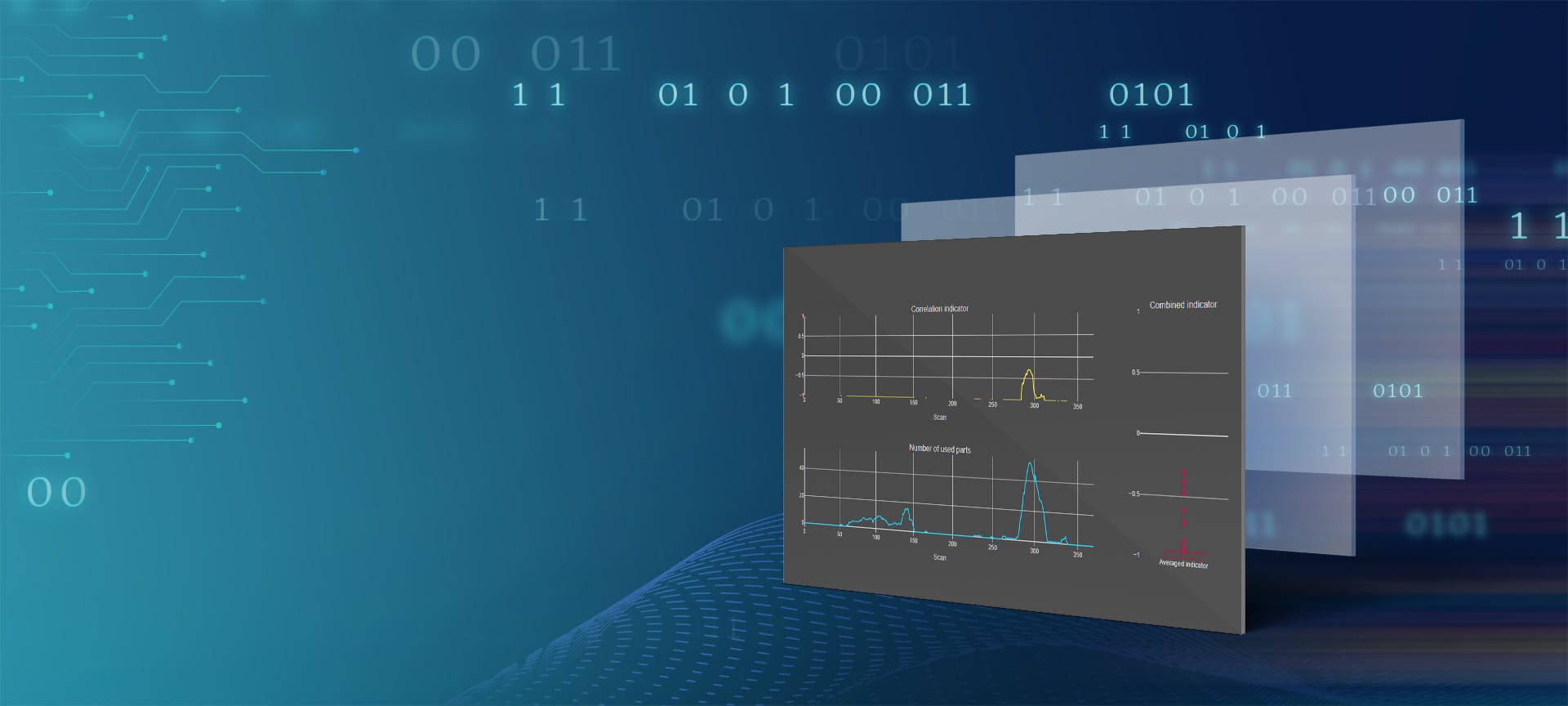

Flawless Axles Thanks to Automated Weld Seam Inspection

Weld Seam Inspection for Axle Components

For Taking Away and Passing On

Brochure

VIRO WSI: Brochure