IV Bag Inspection Patient Safety Meets Efficiency

Automated, Reliable Inspection of Infusion Bags

IV Bag Inspection

Quality inspection of infusion bags presents challenges. It must meet strict requirements to guarantee product and patient safety. At the same time, unnecessary scrap must be avoided.

VITRONIC offers you a cost-efficient yet precise solution. Automation reduces costs compared with a manual 100% inspection and pays for itself within a short space of time. The inspection is reliable and objective, and is stably reproducible over long periods. Defects are detected at an early stage.

Best Inspection Results with Low False Rejects Rates

In infusion bag production, the goal is to reliably detect defects while minimizing false rejects. This can only be achieved in a cost-efficient manner by optimizing inspection processes and automated visual inspection (AVI). The perfectly adjusted systems from VITRONIC achieve the lowest possible false reject rates.

VITRONIC systems are reliable and stable to ensure that your filling processes run smoothly.

- 100%inspection, max. cycle time

Machines Are Objective and Tireless!

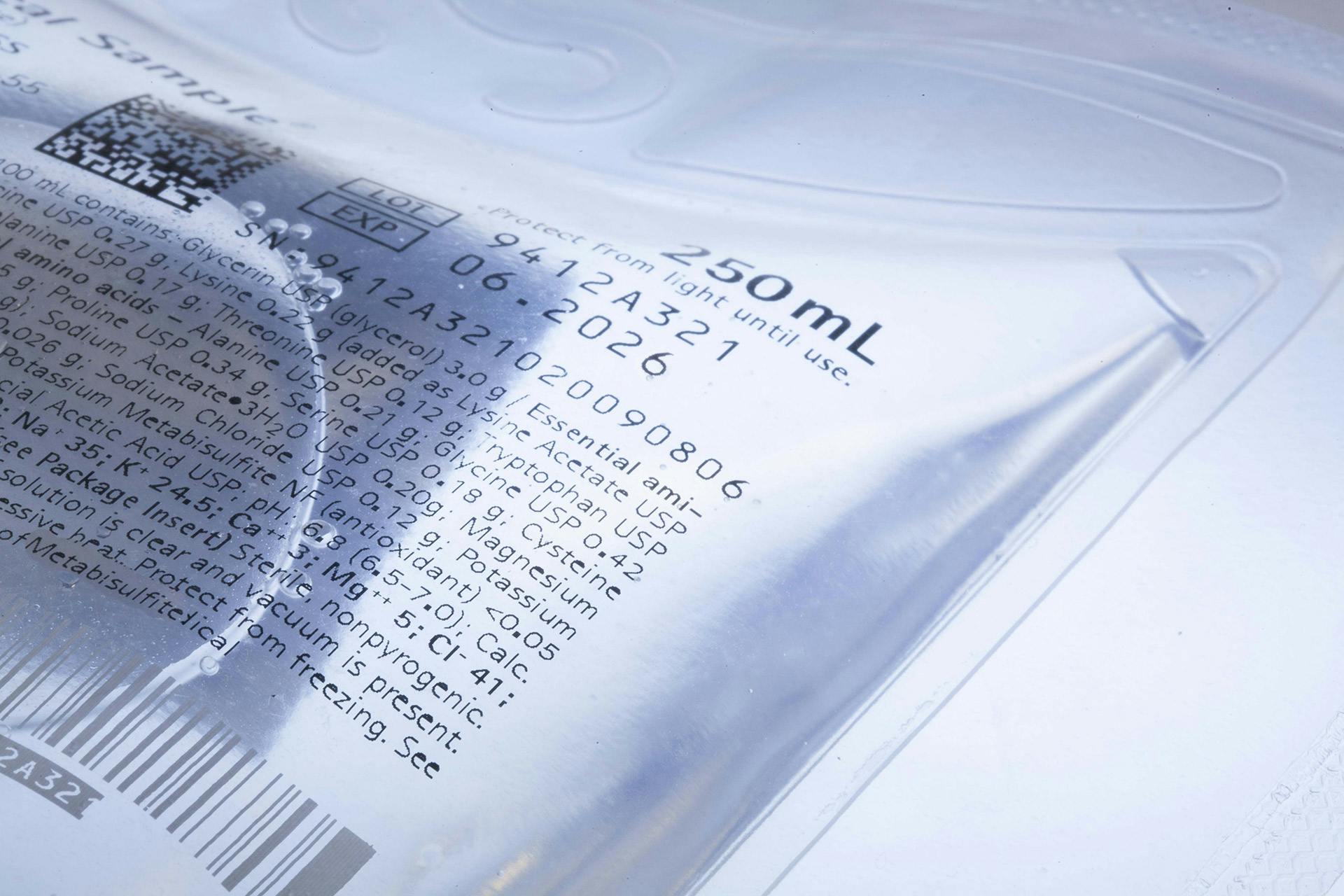

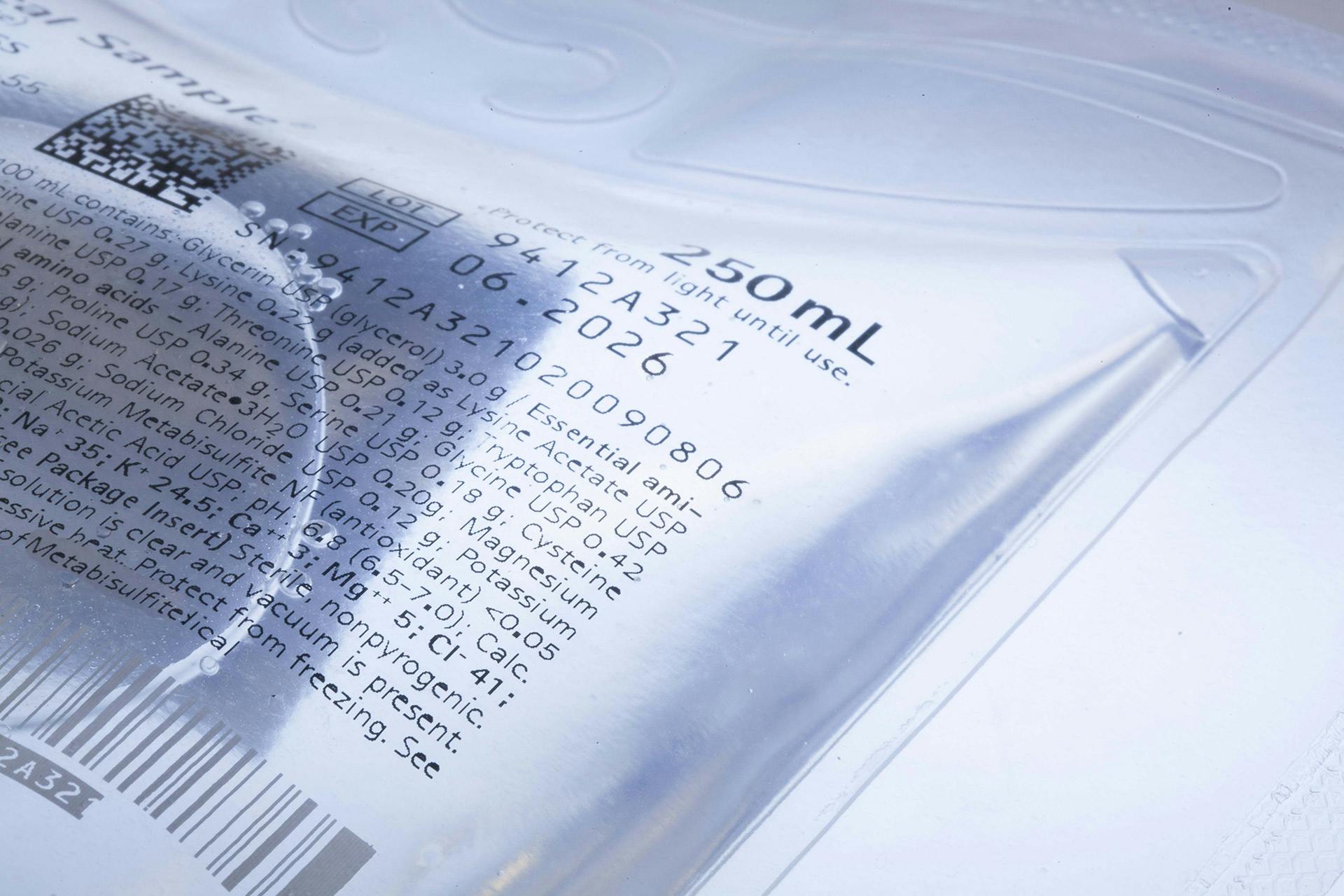

Patient safety is just as essential to your company as profitability. Your infusion bags need to be flawless. There can be no particles in the product and no defects in the bag or at the ports and seams. In addition, there must be no errors in the printing on the bag.

100% defect detection with AVI optimizes product safety, thereby contributing to maximum patient safety.

Consulting Based on Equal Partnership

VITRONIC ensures an excellent analysis of your starting point and your requirements. The next step is to agree on your inspection package. We take a partnership approach and develop the solution in collaboration with you. Your process efficiency increases, because you can rely on project experience and technical expertise, combined with a keen awareness of costs.

You also benefit from a system design with perfectly coordinated hardware and software components, capable of fulfilling the most complex inspection tasks.

Qualification Package – Play It Safe

The VINSPEC HEALTHCARE system can be seamlessly integrated into production lines, enabling automated visual inspection at each process step. The solution uses perfectly coordinated hardware and software, plus an adapted inspection design.

The automated inspection covers quality inspection to detect particles on and inside empty bags, defects on bags, ports, and seams as well as printing errors and code verification.

The inspection solution is constructed on a modular basis in line with your requirements. Individual modules can be adjusted to perfectly meet the need of your complex inspection tasks.