Blow-Fill-Seal InspectionAutomated Inspection Reduces Costs

Visual Quality Inspection for BFS Containers

Blow-Fill-Seal Inspection

BFS Products—Low Costs Thanks to Automated Quality Inspection

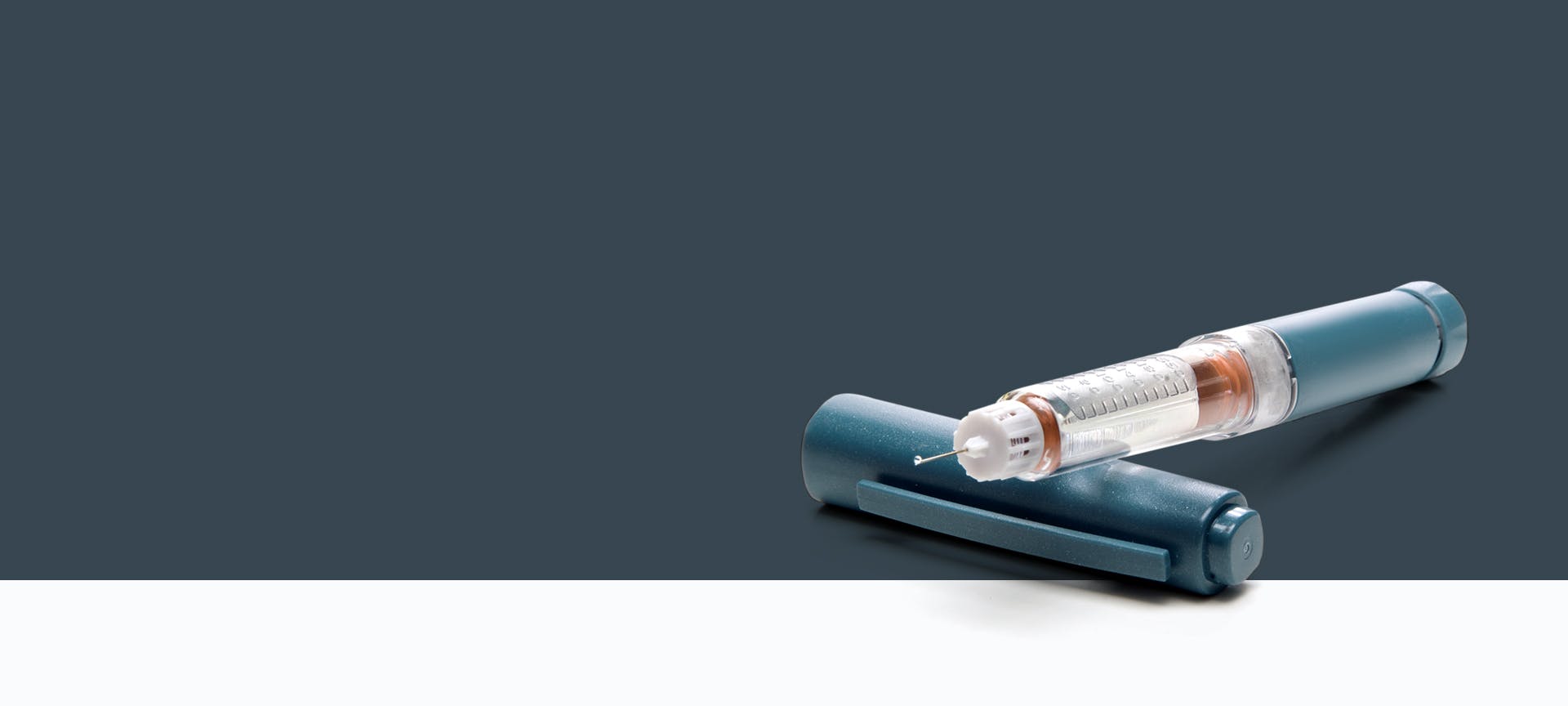

It’s an ingenious invention and the most critical process in pharmaceutical production. BFS containers are manufactured and filled in a single step under clean-room conditions. The strictest hygiene, quality, and GMP requirements must be met. Can you also reduce costs here? Yes! See for yourself.

Inspect Everything - Or Inspect Specifically

AVI Inspects BFS

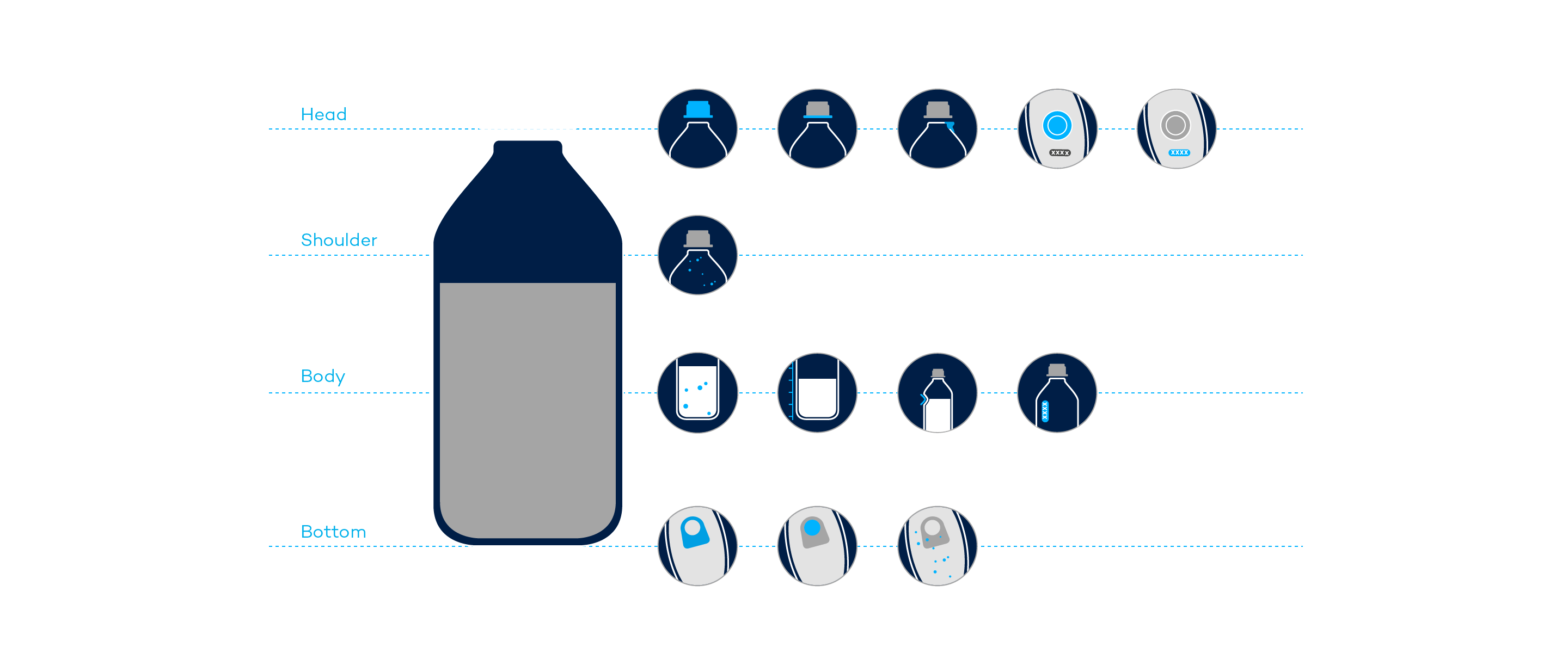

You can easily integrate automated visual inspection (AVI) systems into existing pharmaceutical production lines to detect particles and container defects. Immediately after filling and capping, a comprehensive inspection is performed in serial sequence: cap, shoulder, container and bottom. Modular individual inspections are also possible.

False Rejects—No Thanks!

Automated quality inspection with AVI offers great potential for cost reduction. In particular in the case of a mass-produced product with a relatively low profit margin, costs have to be controlled during manufacturing by using efficient processes and minimizing false reject rates. But that’s not all. Through continuous defect data analysis, processes are optimized in the long term.

- < 0,1%typical false reject rate

Static Inspection Makes the Difference

We specialize in the static inspection of BFS containers. For you, this means that our AVI systems require a comparatively little mechanical effort and thus a small footprint. Our systems are robust and require little maintenance.

In comparison with dynamic inspection units, you benefit from a much smaller initial investment, as well as lower life-cycle costs for maintenance and repair.

Safe Patient Care

Our top priority is reliable patient care. Take BFS infusion bottles, for example. Particles may enter these containers during the manufacturing process. Our software detects particles regardless of which material they are made of and how they came to enter the bottle. Bottles with particles or any other relevant defect are reliably filtered out.

- 100%error detection

- 100%patient safety

Qualification Package – Play It Safe

Maximum Product Safety for BFS

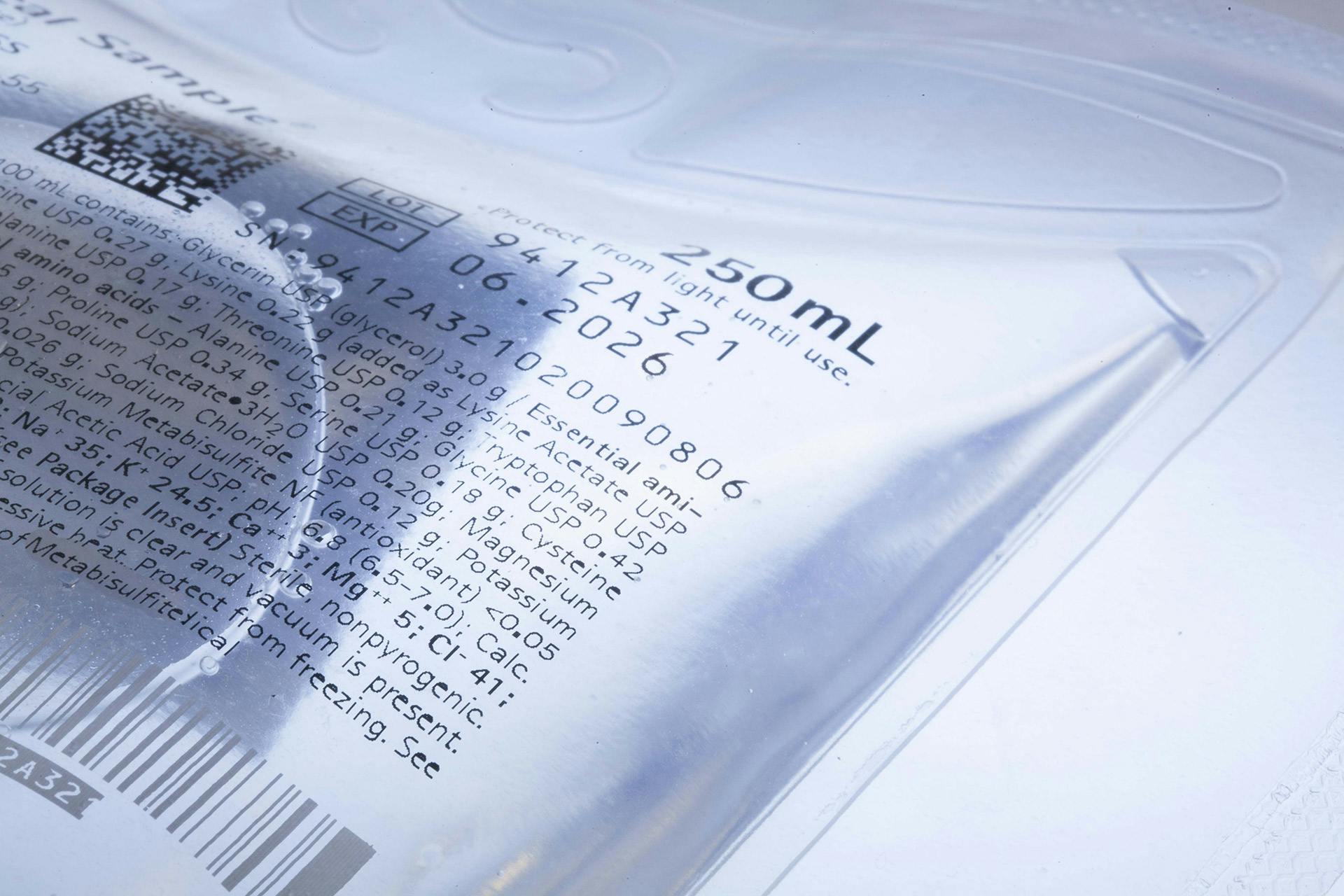

You can integrate the VINSPEC HEALTHCARE AVI system for BFS seamlessly into your production line thanks to its modular design. The solution uses perfectly coordinated hardware and software, plus an adapted inspection design. Its inspection range includes both quality inspections and the identification of codes or printed elements on packaging and labels.