Smart ProductionAutomated inspection of the printing of pharmaceutical products

Visual inspection systems replace patchy spot inspections by humans

Serious consequences of critical printing errors

They are annoying, perhaps embarrassing, but not a big issue: printing errors can hardly be avoided. What we ignore in brochures or operating instructions, however, can have serious consequences in other areas. Printing errors on packaging or labels of pharmaceutical products endanger people's health and lives.

The most important information about medications includes the chemical composition and the dosage level. What can the smallest errors do there? A missing full stop can change 1.0mg to 10mg a tenfold dosage increase. A missing hyphen can change the frequency of intake from "2-4 hours" to "24 hours".

In addition, pharmaceutical manufacturers must comply with numerous standards and laws for product labelling; these can differ depending on the country or region. Even if they are less critical: incorrect labelling can have consequences and does not exactly promote trust in the manufacturer or brand.

Visual printing inspection is challenging

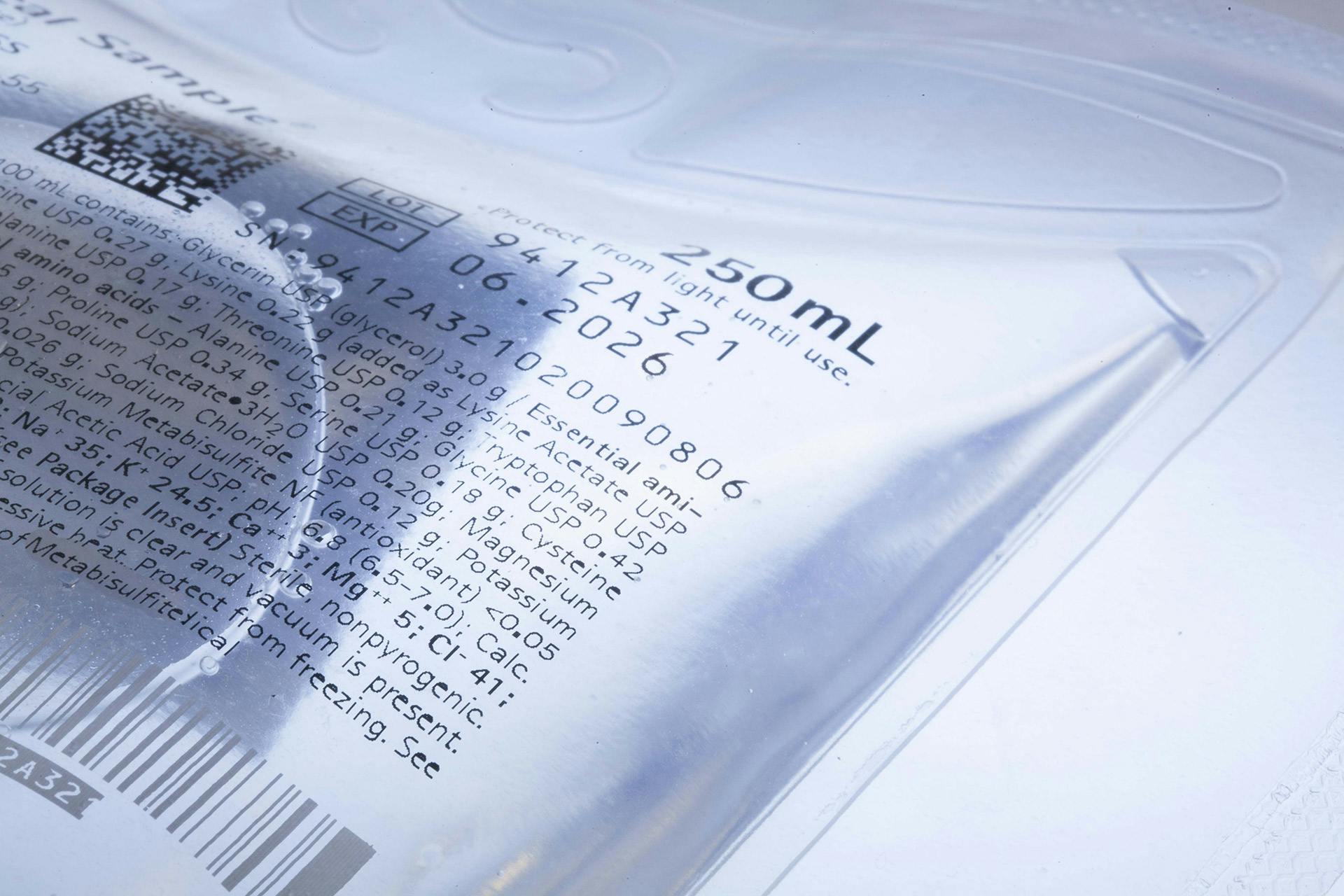

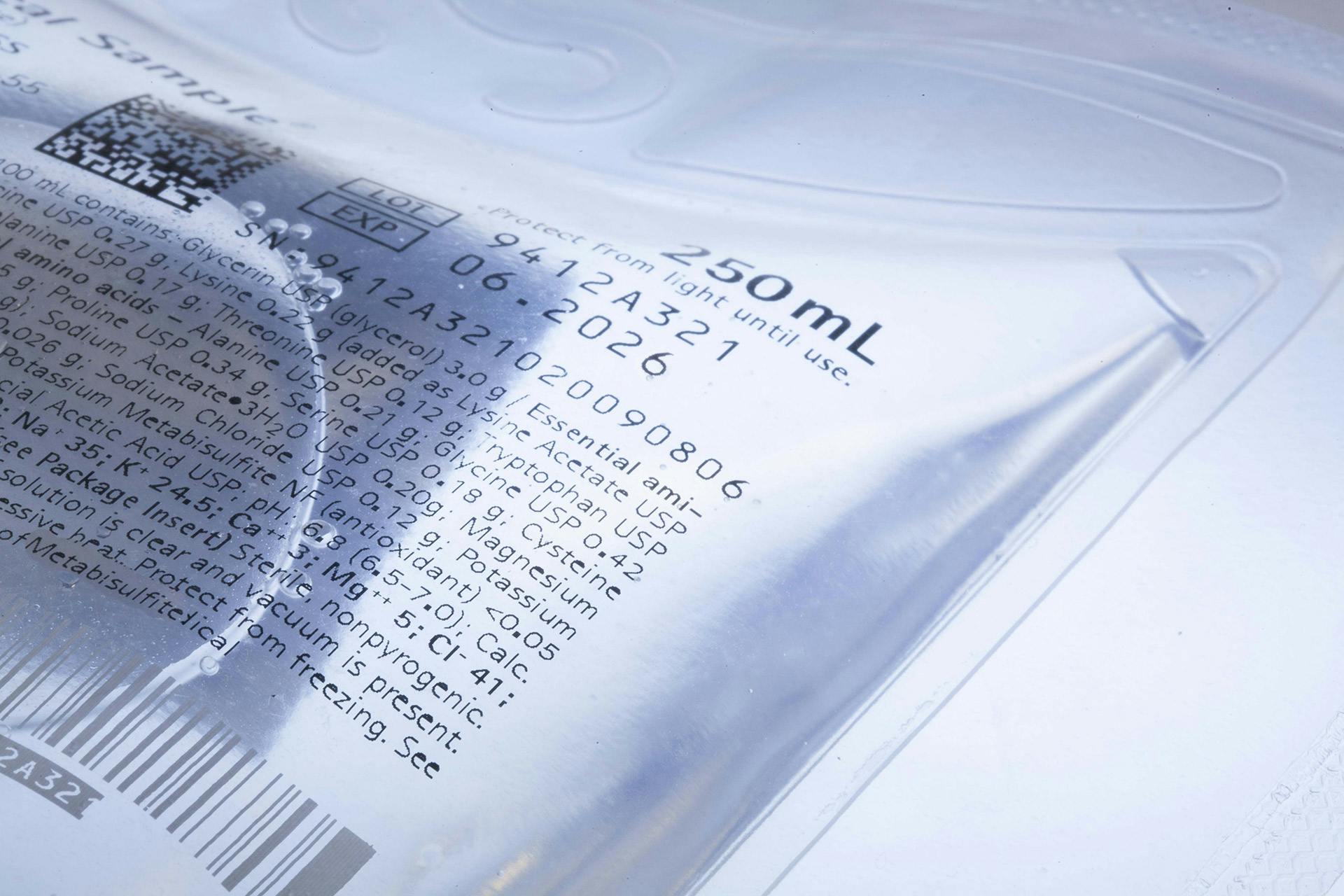

Medicines and medical devices usually require primary and secondary packaging, each of which contains important information. Medicines are packaged in vials, syringes, infusion bags, blister packs, and so on. These containers are again packed in cartons, in sleeves or on pallets for transport.

The containers are made of a variety of materials such as glass, plastic, metal foil, paper and cardboard. The materials are rigid or flexible, glossy or matte, transparent or reflective. Some labels are pre-printed, while others are printed after they are applied to the container. These variables affect how the printed information can be displayed and perceived.

In addition, lettering on flexible or rounded packaging often does not look the same as on a flat surface but is slightly distorted. With glossy and transparent surfaces, the ambient light changes the perception.

All these factors make inspecting the printing a demanding task. Inspectors must compare the original artwork with the finished printing and examine every detail. After working long hours, they may be tired or distracted and could miss errors. In addition, human inspections are performed at specific times on selected samples. Printing errors that occur between these times go undetected, and the faulty packages are shipped.

Testing becomes even more complicated and time-consuming when manufacturers produce for different countries. In this case, inspectors must be familiar with the different regulations and be able to read labels in several languages - or additional inspectors are needed.

Automated inspection provides complete safety

Automated systems are superior to visual inspection by humans in every respect. The biggest advantage is that it allows manufacturers to check all information on all packaging produced around the clock, not just random samples.

The visual inspection systems work with a combination of camera sensors, LED lights and software and inspect the printing directly in the production line. For an infusion bag, the inspection takes about two seconds, for a vial only a tenth of a second.

The speed can be increased via the number of sensors.

Highlight List

- Labels are inspected in several languages.

- It is possible to define which areas are more or less critical and how to react in each case in the event of print errors.

- Changes in print position and print quality are detected.

- Proprietary algorithms eliminate distortions, reflections and other influences from the print image and compare it with the original.

- Recordings of print errors are saved to help identify possible causes.

- All test data is recorded over a longer period. They can be exported to other systems, for example to create data analyses for process optimization.

Manufacturers can easily implement internal compliance rules with automated auditing. The systems are password protected; all manual changes must be approved by a second person and are traceable.

Ideally, manufacturers already think about automated printing inspection during product development. The better the packaging design is prepared for the inspection systems, the better the results will be.

At VITRONIC, we advise our customers during the development phase on which elements are easy or difficult to inspect and which changes to the design make it easier for the system to detect errors. In this way, the most efficient, customized inspection systems can be designed - systems that are also already equipped for tomorrow's products and requirements.

Summary

In Short

- Incorrect labeling on pharmaceutical products can endanger human health and life.

- Due to the different materials and labeling, package inspection is extremely challenging for human inspectors.

- Manufacturers use automated inspection systems to ensure that labeling is 100 percent correct and compliant with the law.