Menü

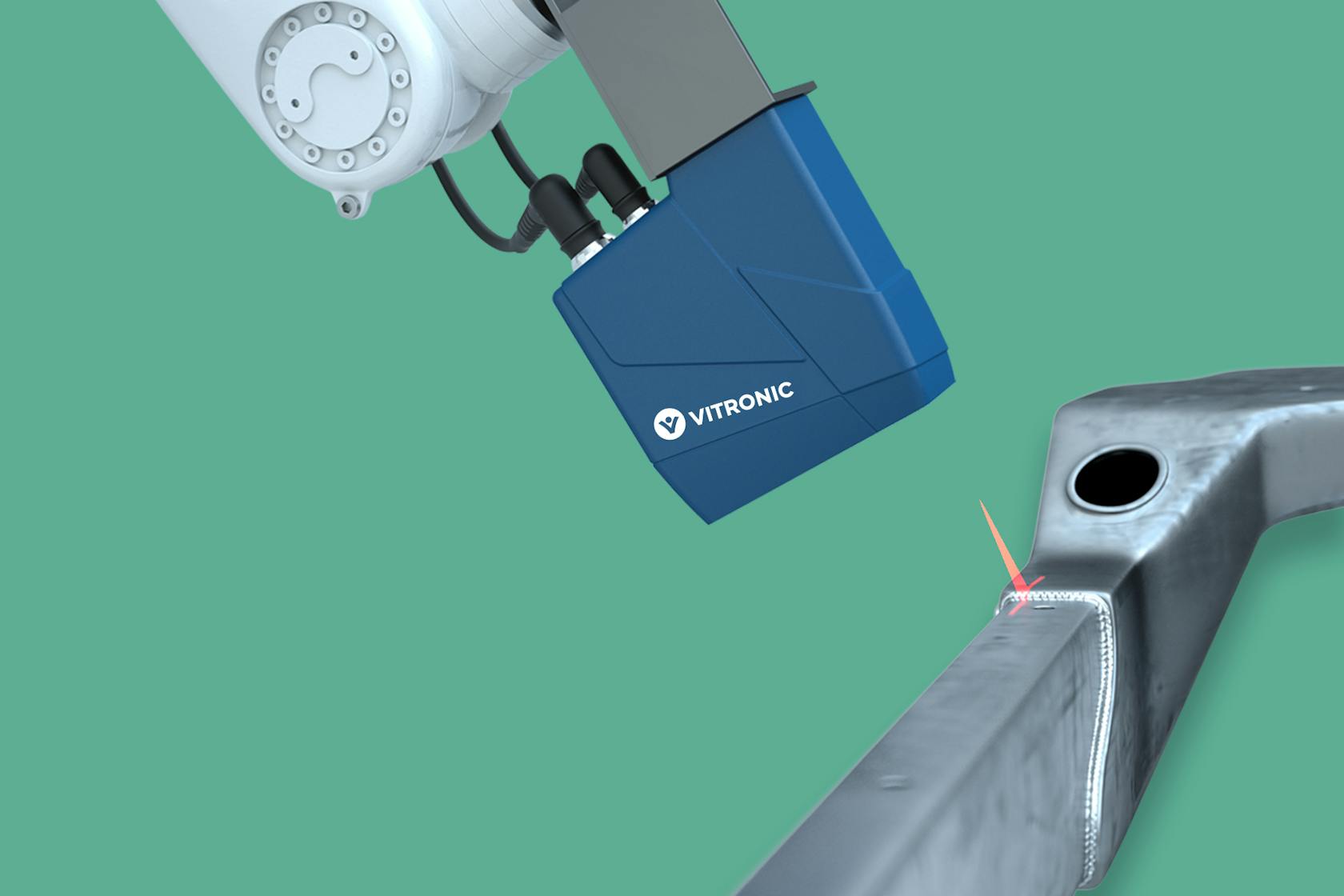

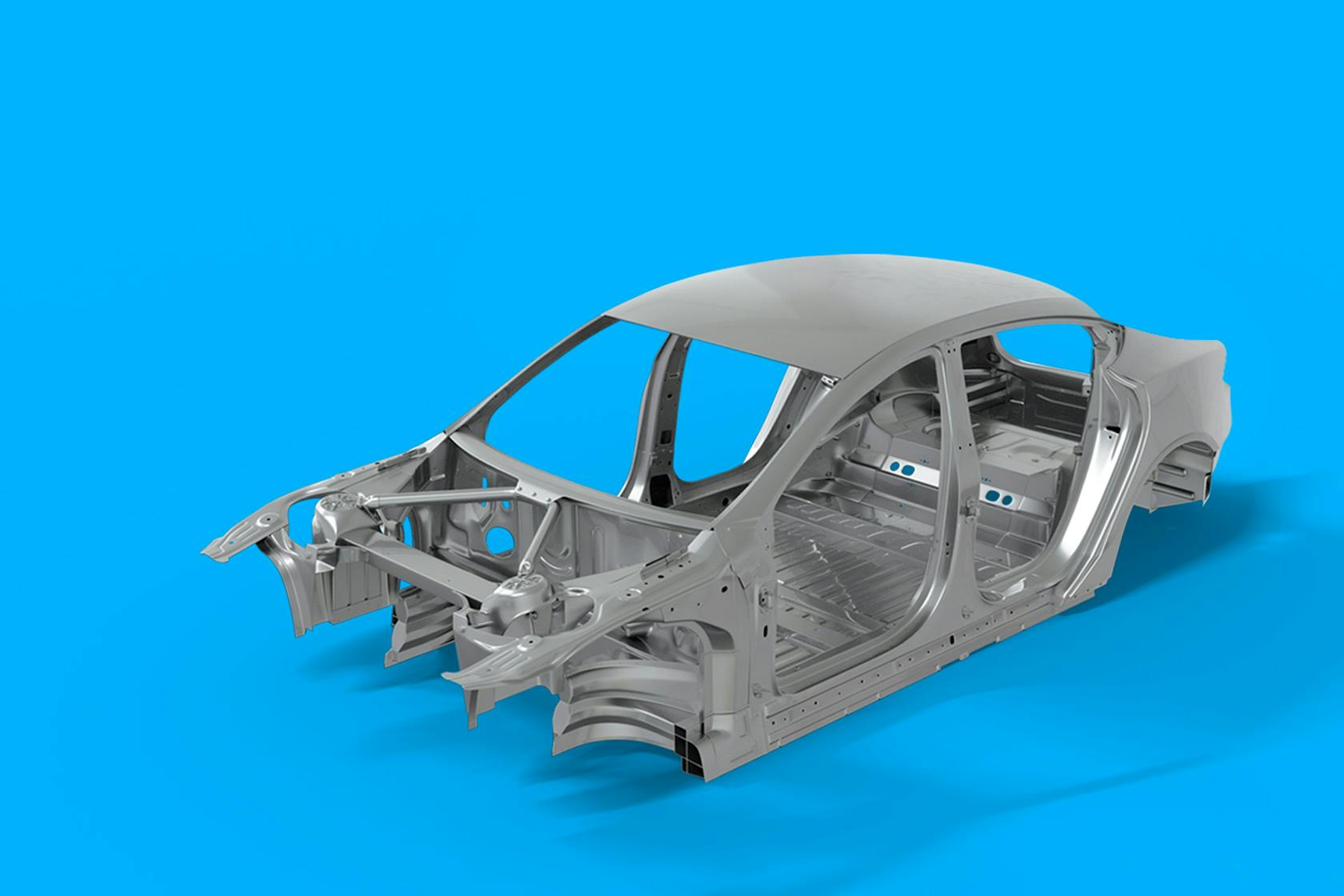

Solutions Automotive Automated Inspection Systems for Automotive

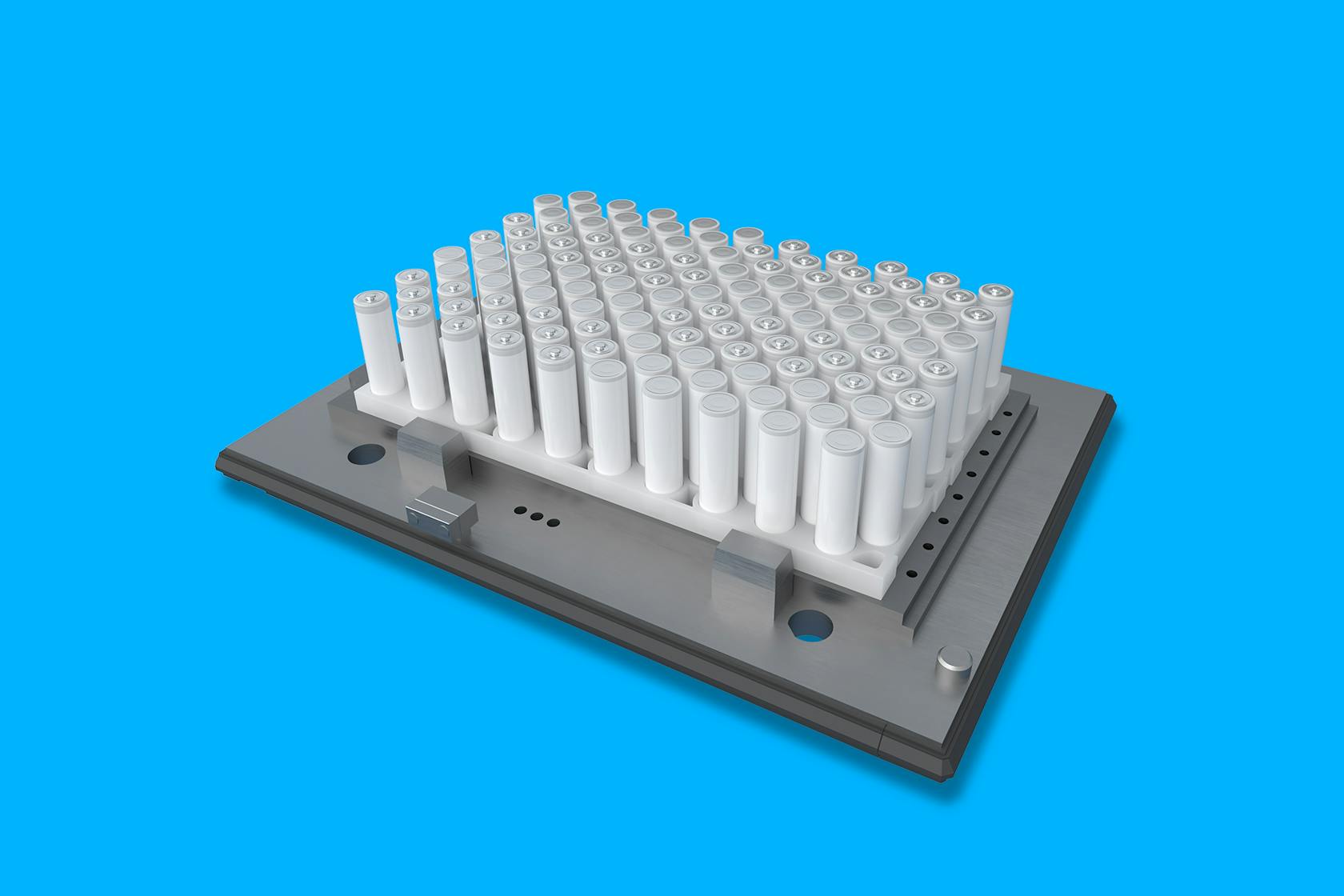

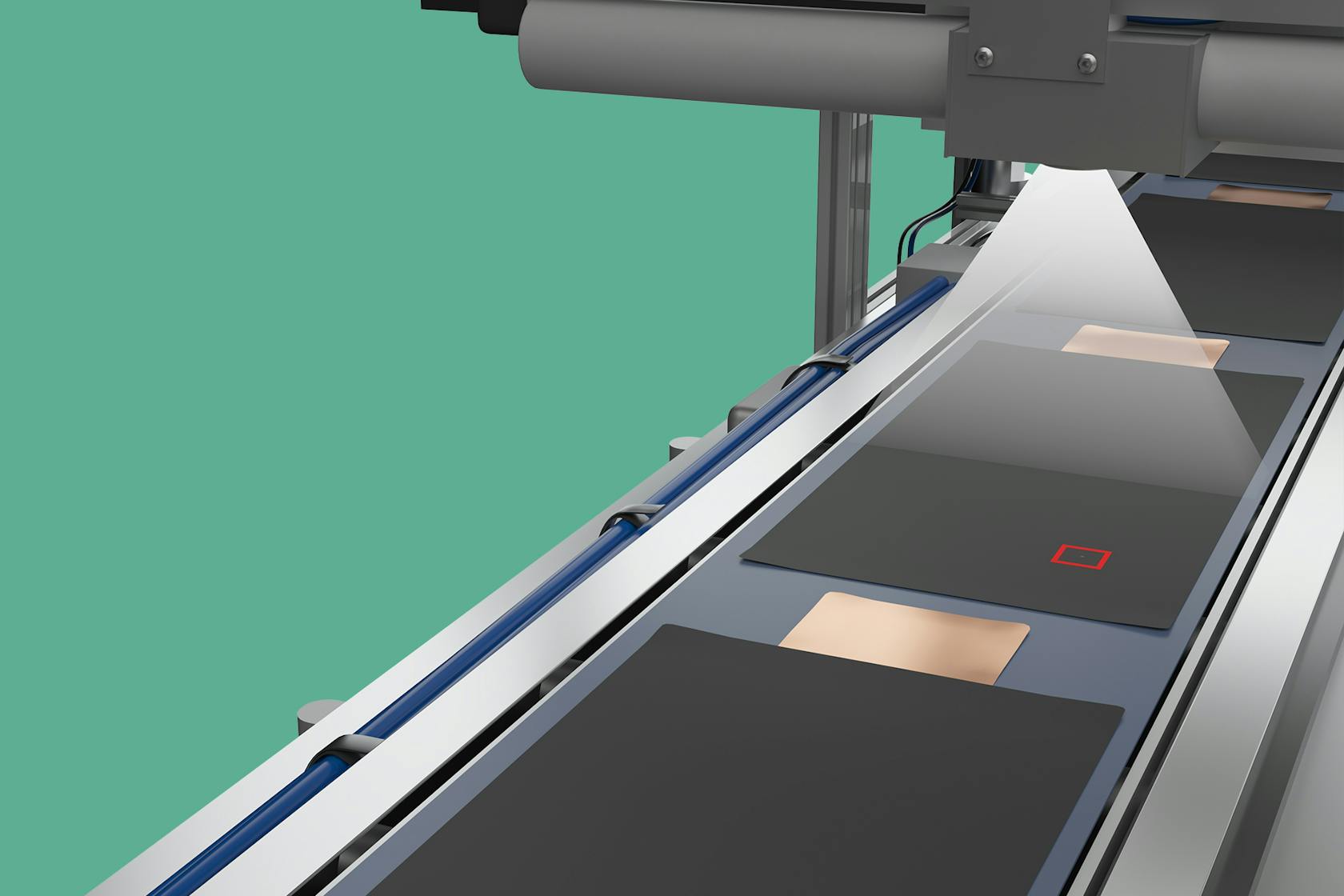

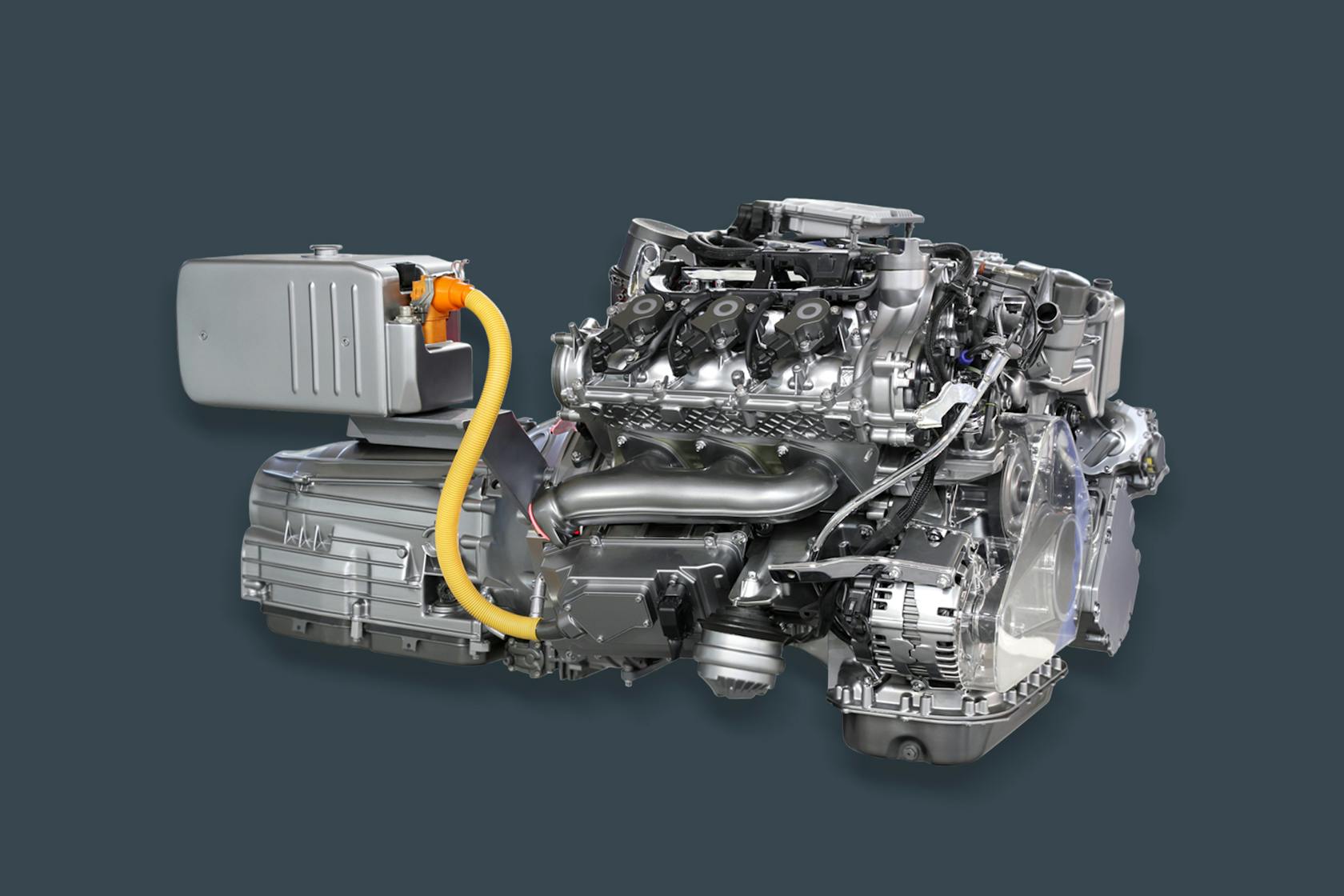

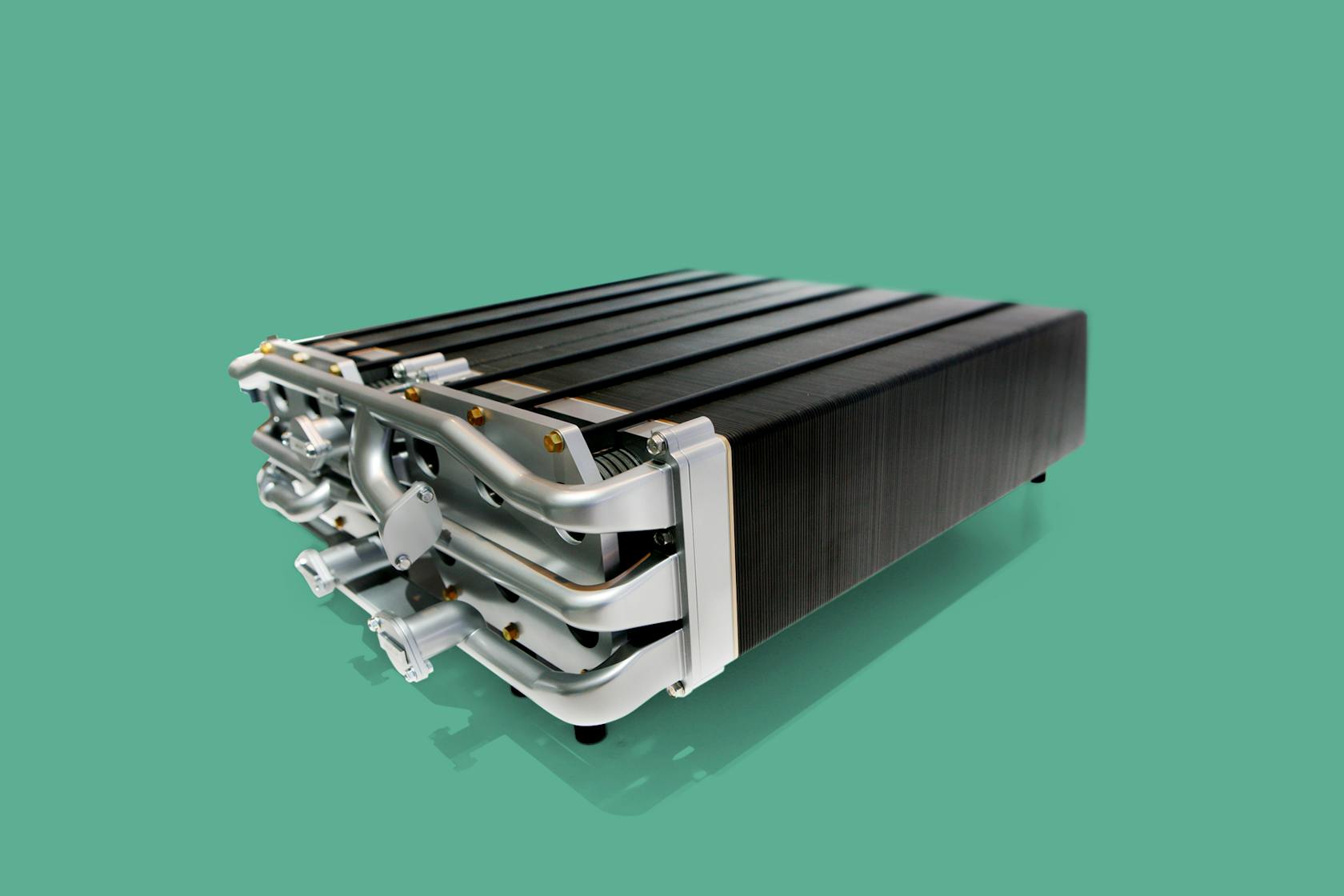

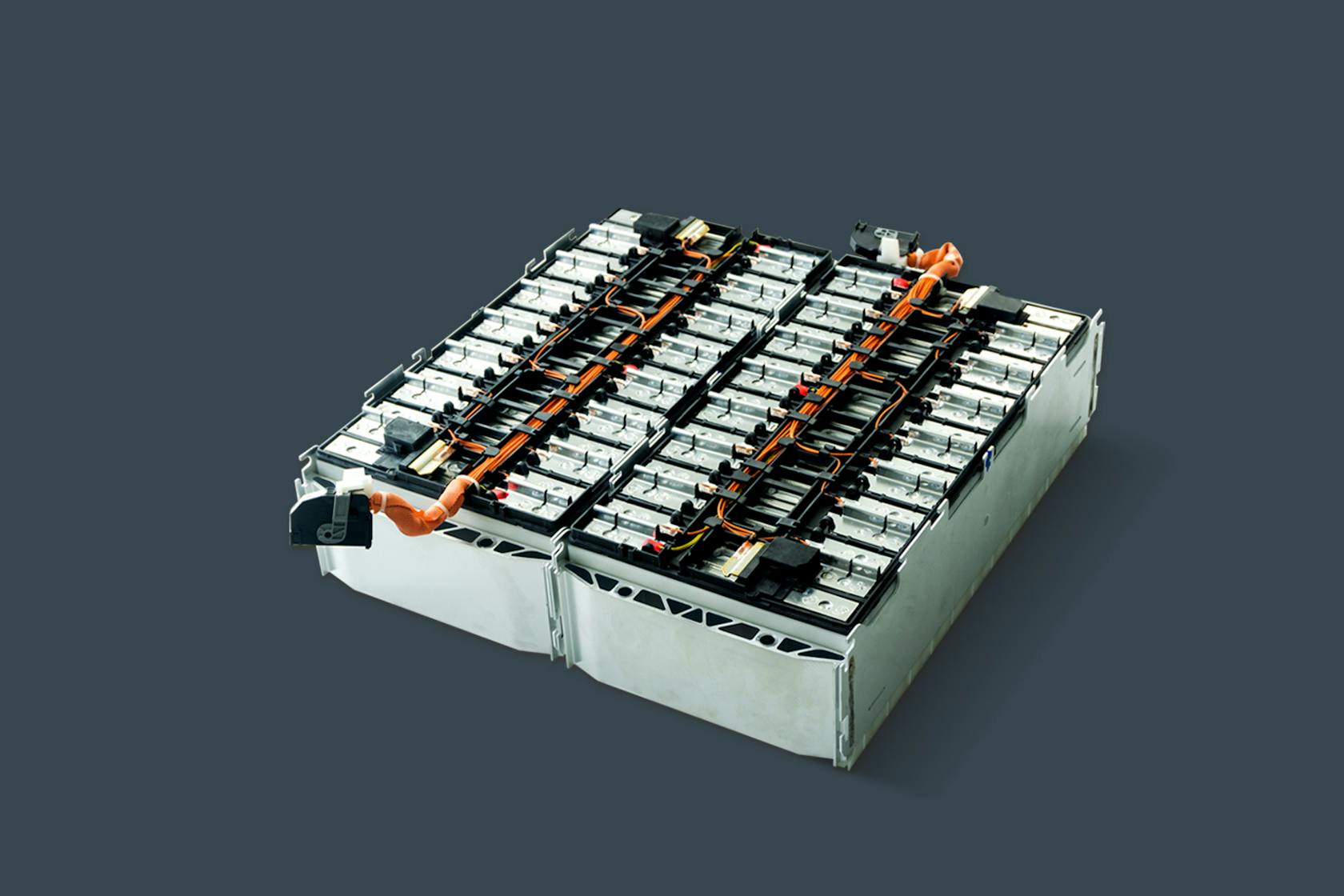

Since 1995, leading OEMs and tier-1 suppliers worldwide have been using our inspection systems in production. As a reliable partner, we’re always ready to assist customers in the traditional automotive markets—and support them as they enter future markets, such as electromobility.

Industry

Automotive

Application Area

Please choose