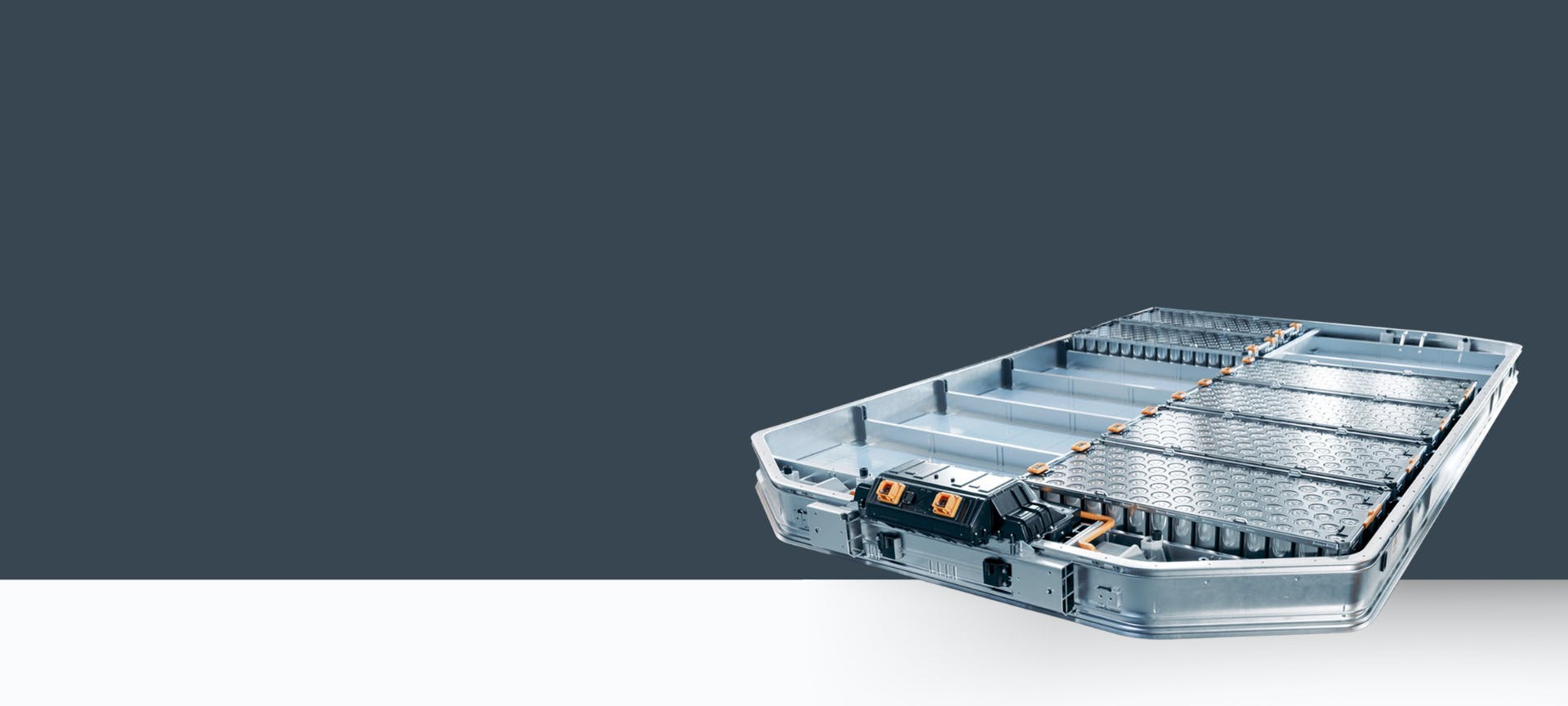

Battery Tray Quality InspectionDefect-free e-vehicle battery trays

Visually inspect all safety aspects - fully inline and automatically

Battery Tray Quality Inspection

Visual inline quality inspection of battery trays - the comprehensive solution

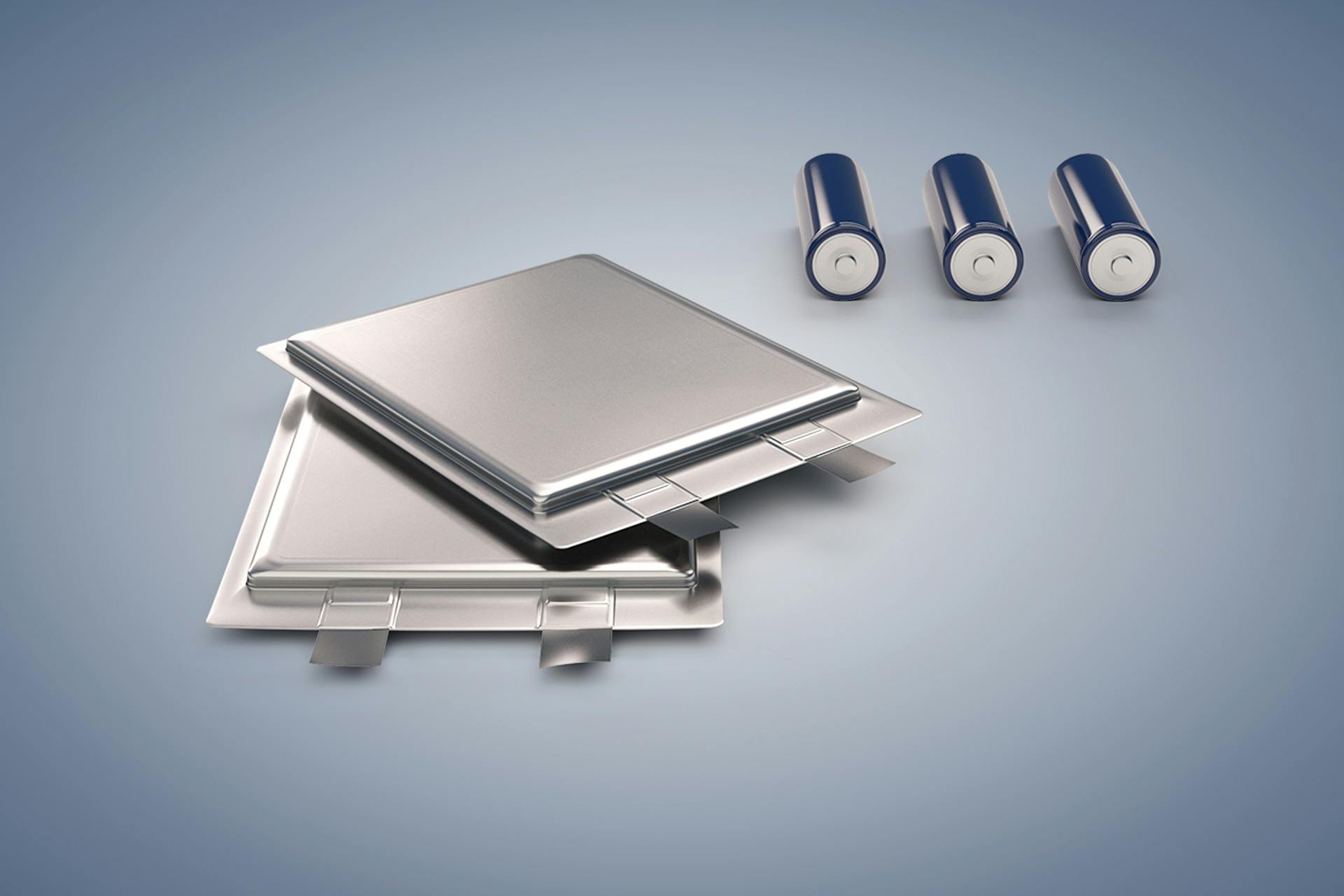

The battery tray holds the most valuable and critical component of an e-vehicle. Highest demands on safety and quality are therefore a necessity.

At the same time, you as a manufacturer must produce at competitive prices.

With the visual inspection systems from VITRONIC, you bridge the gap between these goals: Use them to inspect weld seams, surfaces, and fastenings on the battery tray inline. The solutions support your highly automated processes and enable a zero-defect strategy.

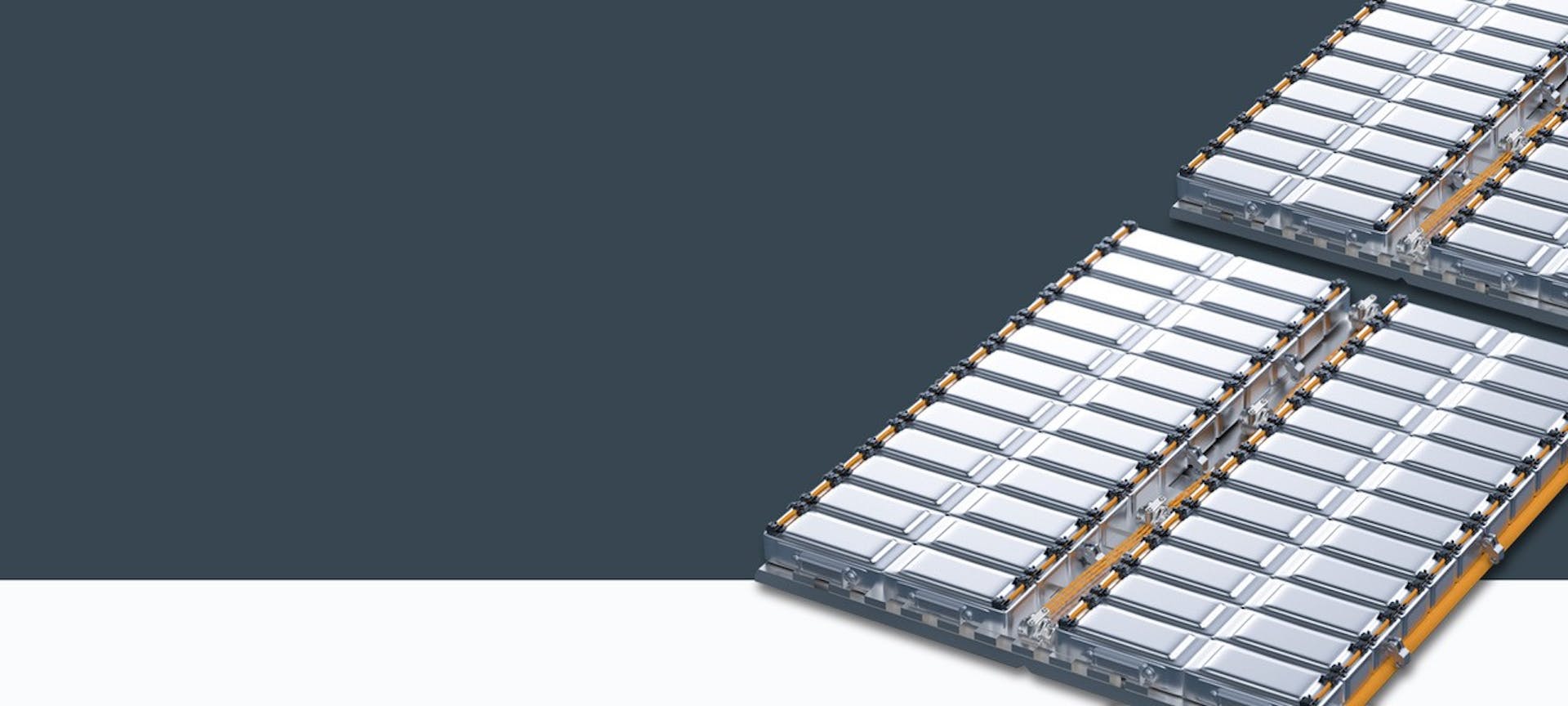

Detect defective welds

Deliver battery trays with 100 percent flawless welds.

VITRONIC inspection systems detect the smallest welding defects: seams that are too thin, pores, incorrect connection angles and much more. They master all welding processes that are used: MIG/MAG, laser, laser hybrid and friction stir welding.

Through monitoring, deviations in laser welding can even be detected in real time during the welding process.

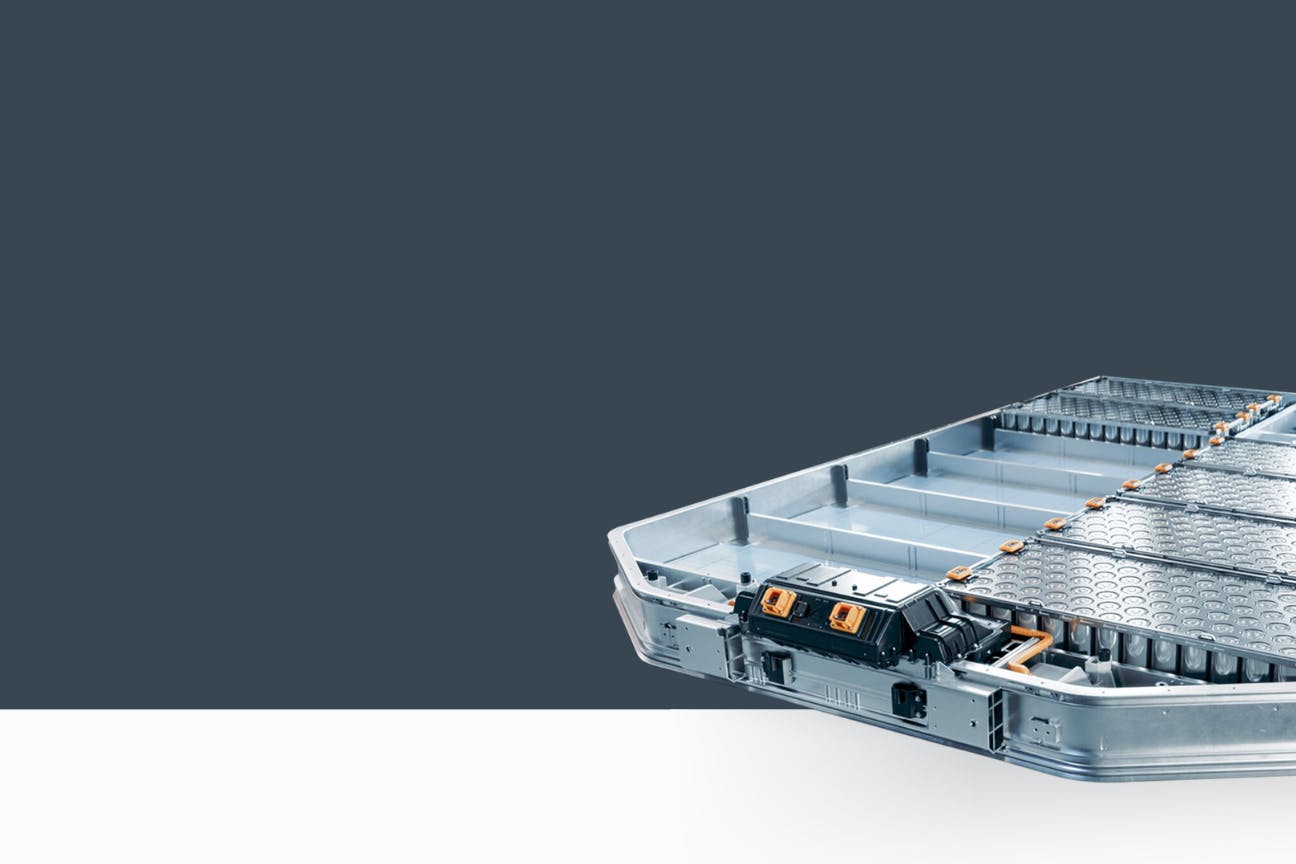

Detect dirty and damaged surfaces

Ensure that components are technically clean and function properly.

Check all surfaces of the battery housing for contamination by particles, weld spatter, as well as damage such as scratches.

Detect missing and improper fasteners

Make sure that all fasteners are correctly attached to the battery tray.

The inspection system can detect whether screws and rivets of all types are present and attached at the correct angle. It also detects other materials such as adhesive film, foams or sealing rings.

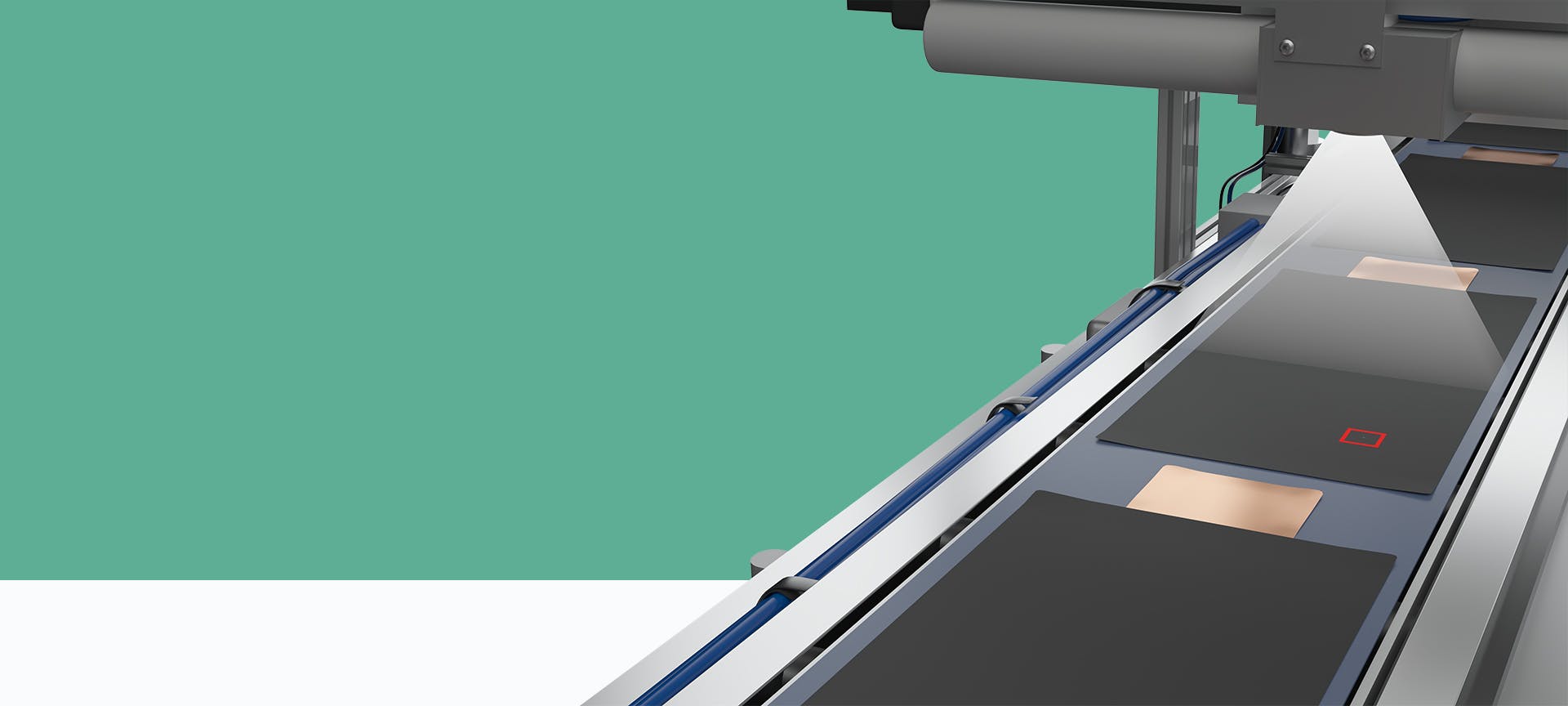

Efficient inline inspection

Fully automated and reliable

No defect slips through the inspection systems. They examine every spot on every single battery tray, 24/7.

As a manufacturer, you don't need human inspectors and can automate to a greater extent. You reduce your scrap and manufacturing costs and avoid costly complaints and recalls.