Solutions Healthcare Innovative visual inspection solutions for the pharma industry

The pharmaceutical and medical device industries are subject to the most stringent quality requirements. Healthcare and patient safety always come first. Automated visual inspection solutions from VITRONIC ensure the highest quality standards by completely eliminating defects during pharma production. They also enable 100% inspection at full capacity utilization.

5 Applications in Healthcare

In the complex and strictly regulated environment of pharmaceutical production, ensuring the highest quality and safety plays an outstanding role. This is where VITRONIC, as a pioneer in the field of automatic visual inspection systems, sets standards to meet the demanding requirements of the pharmaceutical industry.

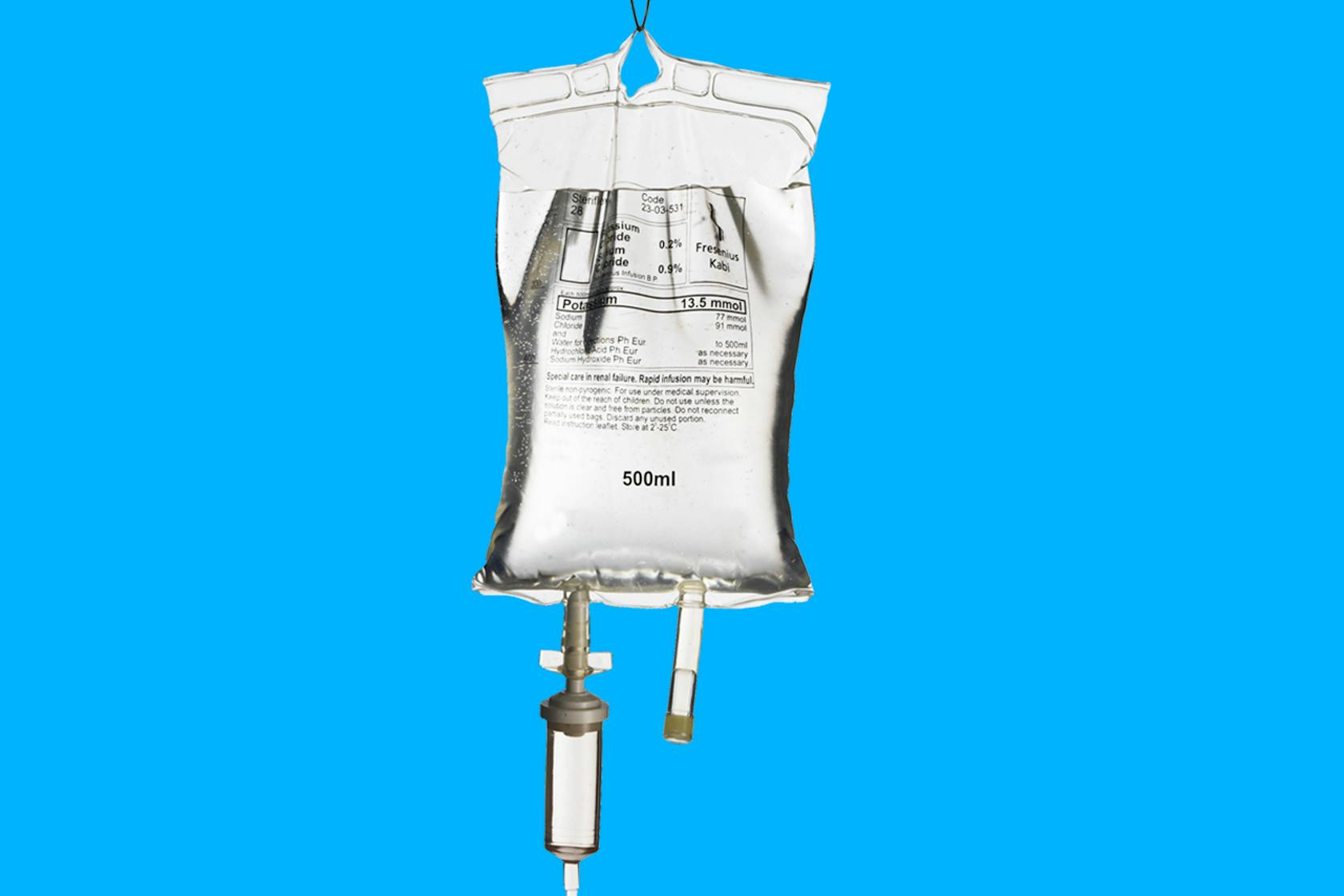

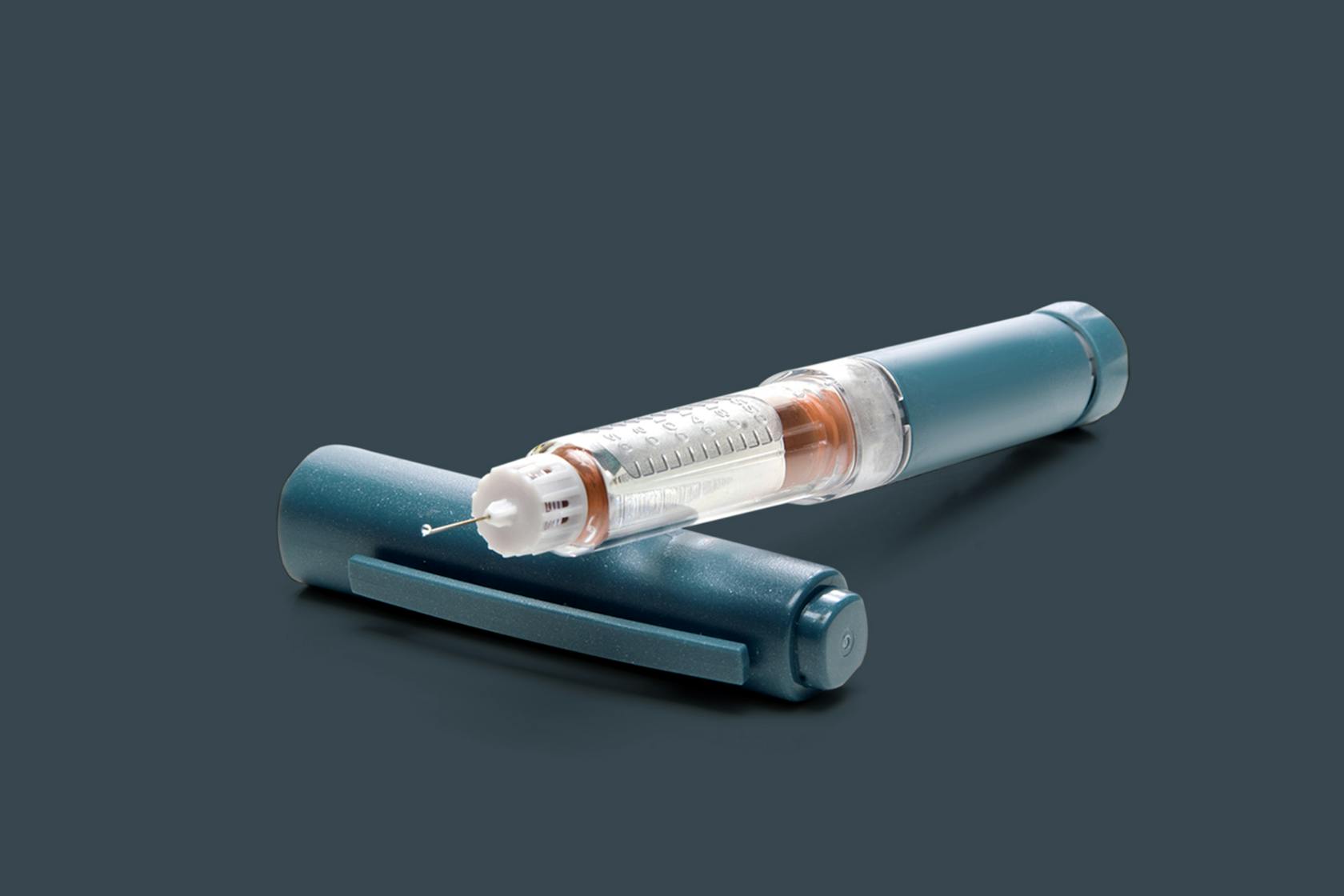

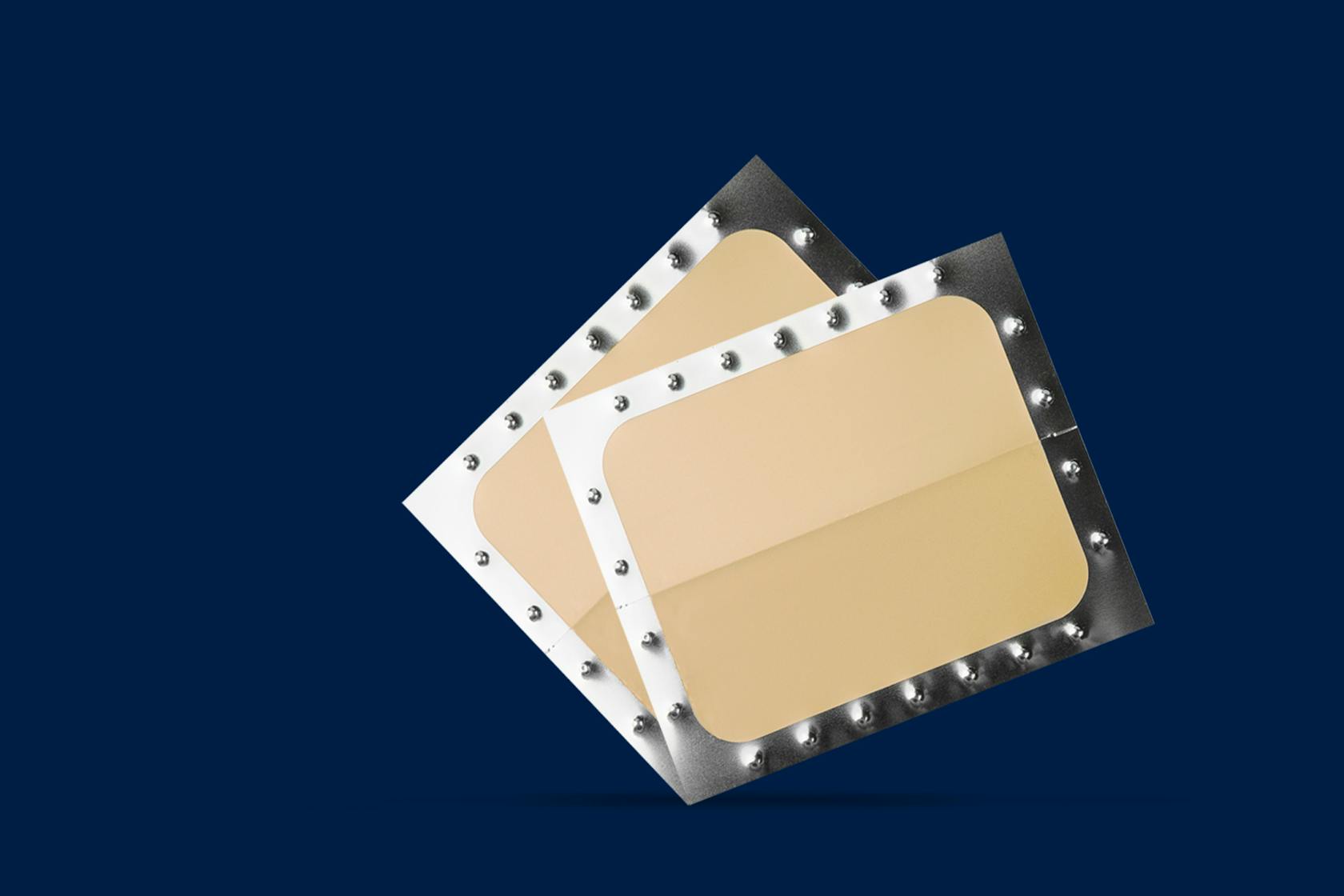

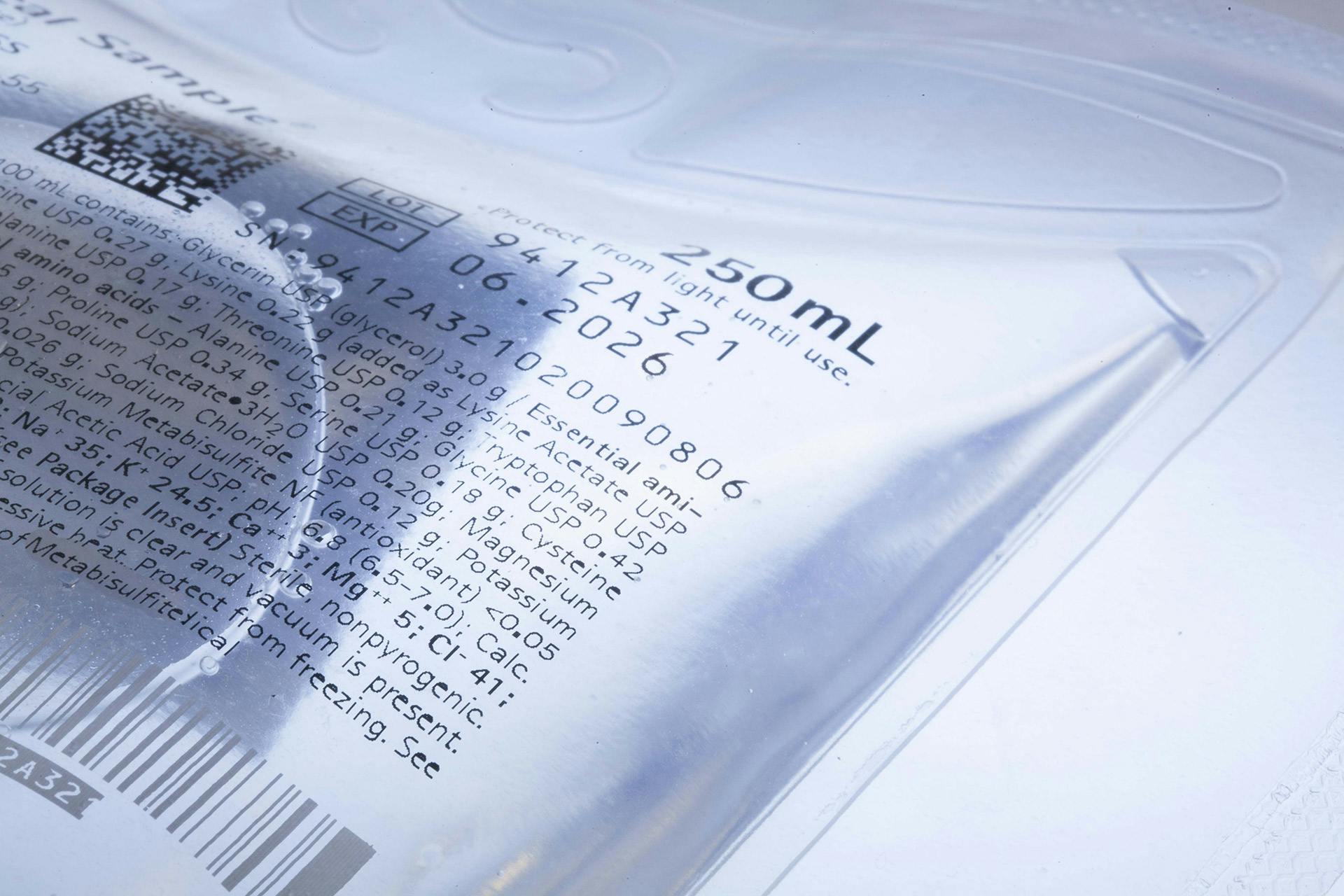

Precise particle inspection of pharmaceutical material such as transdermal patches, infusion bags and insulin pens is of critical importance. The slightest deviation can have serious consequences, which is why accurate detection of the finest particles is essential. State-of-the-art inspection systems from VITRONIC ensure reliable and efficient identification of contaminants, protecting the integrity of the products.

Ensuring the quality of pharmaceutical packaging such as blow-fill-seal containers, vials and crimp caps is at the heart of VITRONIC's responsibility. The critical role of these components in protecting the sensitive contents requires the highest testing accuracy. VITRONIC uses pioneering technologies to detect the smallest deviations or defects to ensure consistently high product quality. This automation approach minimizes human error sources and ensures effective preservation of product integrity.

Pharmaceutical manufacturing is characterized by an extraordinarily low tolerance for error, as even tiny defects could have serious consequences for patient safety. VITRONIC meets this demanding challenge by providing automated visual inspection systems that not only meet the required standards, but exceed them. The integration of state-of-the-art image processing technology and intelligent algorithms into VITRONIC's systems reflects its commitment to meeting the stringent requirements of the pharmaceutical industry.

In an industry where quality and trust are paramount, VITRONIC's automated visual inspection systems are indispensable. They help ensure compliance with strict regulations and increase patient confidence in pharmaceutical products. VITRONIC remains the driving innovator, pushing the boundaries of precision and reliability in pharmaceutical inspection through continuous technology development - for the health and safety of people worldwide.