Automated Weld Seam InspectionSmart Production with Intelligent Inspection

The future of weld seam inspection

Automated Weld Seam Inspection

The future of weld seam inspection

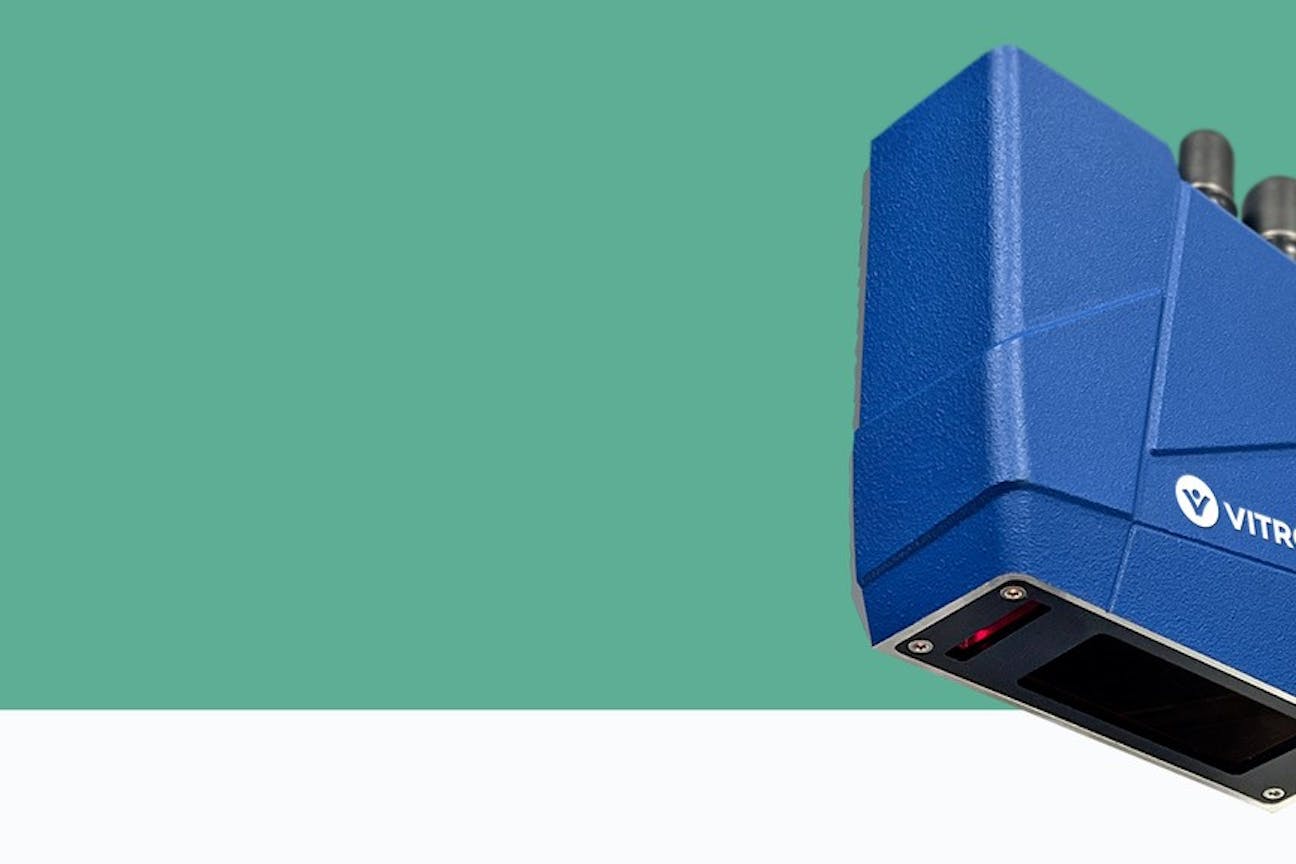

Automated and digitized weld seam inspection is becoming a decisive strategic factor. With integrated AI algorithms, VIRO WSI is one of the innovation drivers for this change. VIRO WSI is an optical, automated inspection system that captures weld seams inline and in real time, measures them in three dimensions, and evaluates them based on defined quality criteria. The system thus represents a solution that not only captures data, but also makes it usable as a basis for decisions. The path to intelligent, resilient manufacturing begins with your quality assurance—digitized, data-driven, and AI-supported.

More precise evaluation of what constitutes quality

With VIRO WSI, you can detect defects such as pores, seam interruptions, or underfills with a resolution of up to 0.0125 mm. Even reflective surfaces, flat seams, or complex geometries are accurately detected regardless of material, seam shape, or component position. AI supports you with particularly difficult-to-detect or irregular defect patterns: it recognizes patterns, identifies deviations, and creates the basis for even more accurate decisions.

Complete traceability for reliable decisions

VIRO WSI automatically records all relevant weld seam characteristics, from seam width to pore distribution. Each test is documented with precise component and position information, including a time stamp, error classification, and limit value violations. This complete traceability is essential for compliance with standards, auditability, and customer assurance, especially in safety-critical industries. VIRO WSI creates the conditions for this with a database that is traceable, evaluable, and verifiable at all times.

Exceptional inspection range with precise classification

VIRO WSI recognizes and classifies a wide range of seam characteristics, deviations, and defects inline. Detection is independent of the operating personnel and remains stable even with varying geometries or materials. AI brings consistency to the evaluation of complex defect patterns by recognizing recurring patterns and objectively supporting decision-making.

Data as the basis for targeted process optimization

VIRO WSI provides you with more than just test results: you receive a database that allows you to optimize quality in a targeted and efficient manner. Through series comparisons, trend analyses, and error classifications, you can recognize patterns, identify weak points, and adjust parameters based on data. Your analyses will also evolve—from reactive evaluations to intelligent control decisions. With VIRO WSI, you can actively pursue this path: structured, scalable, and prepared for the next level of data-driven quality assurance.

Ready for tomorrow’s advancements

VIRO WSI is designed for increased functionality. The platform has a modular structure, is scalable in its application, and is prepared for future developments. New materials, additional process steps, or changed quality specifications can be flexibly integrated. Software updates and AI enhancements continuously expand the system's performance. And the interaction between VIRO WSI and Weldloop software creates a networked data architecture. Test data is combined with process parameters to reveal correlations and enable targeted evaluation and optimization of welding processes.

Designed for cross-industry use

VITRONIC has been developing systems for visual quality control on weld seams for over 30 years. VIRO WSI builds on this experience and combines it with the requirements of the future: AI-supported analyses, expandable data structures, and reliable traceability. You benefit from a platform that is available long-term, modular, and validatable. This allows you to increase your productivity, reduce time and personnel costs, and secure investments. With a solution that delivers results from day one and grows with your requirements.