Smart LogisticsLogistics in change: Focus on the Middle East

Adaption is key in the fast-moving logistics environment

The Middle East as a hub for the whole MEA region

What used to be a region known for oil, sand and heat is now home to some of the fastest growing economies in the world. Especially the UAE managed to overcome the challenges of the global pandemic with remarkable success and stand stronger than ever as a gateway for business and economy for the whole MEA region and as one of the top-destinations for tourism worldwide.

With its fast-paced developments, the Middle East is also quickly becoming a logistics hub for the MEA region, handling goods and packages for many different regions.

Logistics for the Middle East and Africa

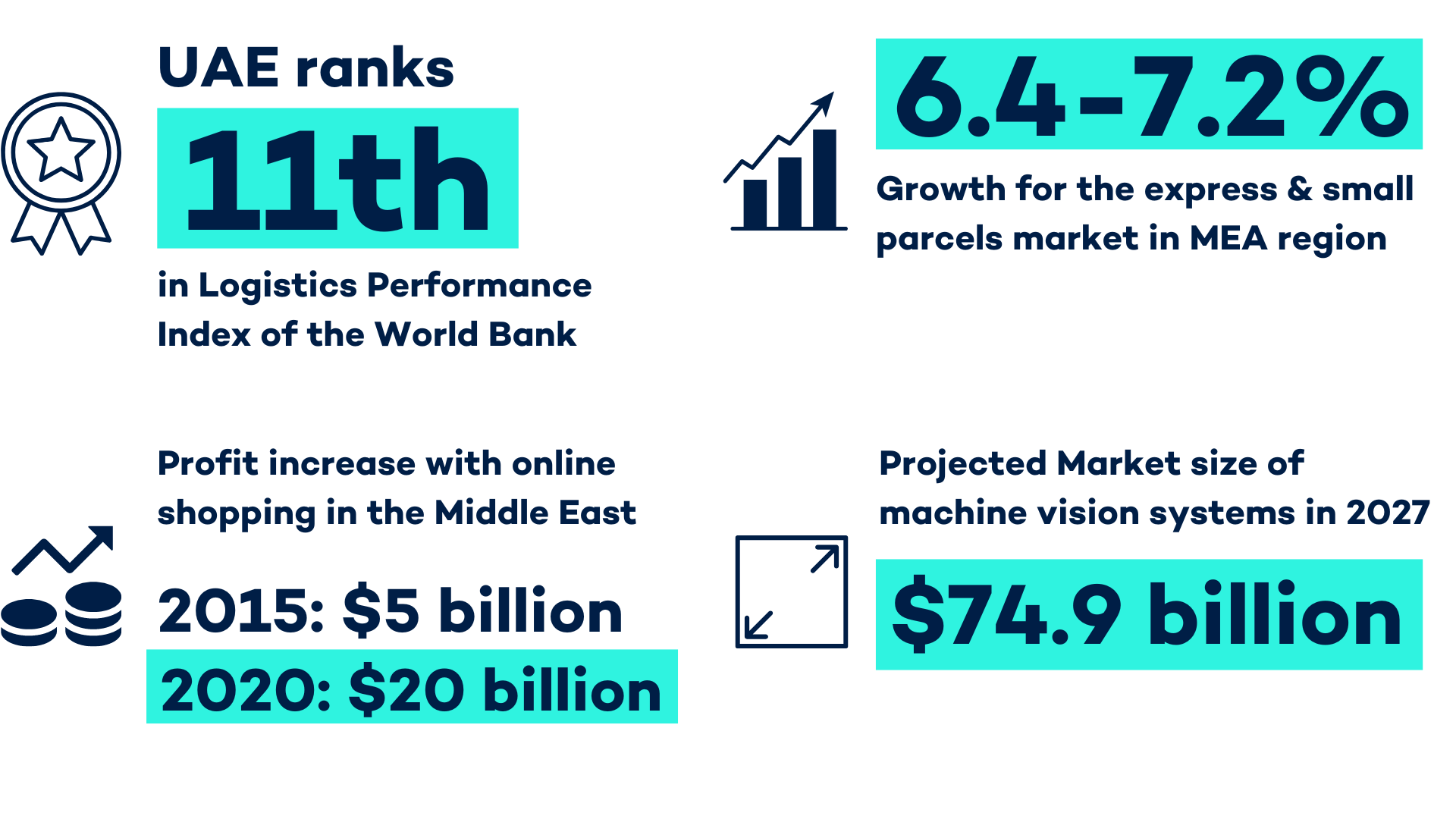

The best performing country in the region are the UAE, scoring 11th rank in the Logistics Performance Index of the World Bank, ranking higher than Hong Kong, Switzerland and the United States. Especially when it comes to timeliness, the UAE are one of the best performing countries, with only Belgium, Denmark and Germany scoring better.¹ As there is already a lot happening in the logistics sector in the region, new projects are yet to come, including the Saudi Railway Company’s (SAR) plan to build rail links into neighboring countries and the new rail connection in the UAE by Etihad.²

Numbers also show that the growth rates for the express and small parcels market remain to stay high in the MEA region over the last decade, ranking between 6.4% and 7.2% annually.³ This growth is fuelled by different aspects, namely infrastructure development, a boom in e-commerce and increase in cross-border trade, especially in the UAE.⁴

Challenges and Opportunities

While the logistics sector in the Middle East is evolving fast, the crucial technology to tackle future challenges has not yet become the standard in the region. With comparably low costs for manpower, many steps in the logistic supply chain are still done manually. Companies in the Middle East have easy access to low-cost manual labour, which causes them to be less ready for a high initial investment in automation technologies.⁵

However, the global pandemic has initiated a slow shift, as logistics companies faced many issues due to lockdowns and a sharp increase in demand, especially through online and mobile shopping.

The profit of online shopping in the Middle East has experienced a significant increase, from $5 billion in 2015 to $20 billion in 2020.⁶ The development in online shopping profits indicates not only to a higher amount of parcels and goods, which have to be handled in Middle Eastern hubs, but also a shift in how supply chains work in the region.

With projected further growth, automated solutions are a main asset in remaining competitive worldwide, as also costs for manpower are increasing.

Machine Vision as a game-changer

The importance and relevance of machine vision systems in general can be seen in the market size of the industry overall. While in 2019 it was valued at $29.7 billion, it is projected to reach $74.9 billion by 2027. Reasons for this are various. However, a lack of manpower and the growth in demand for AI are some of the main drivers creating market opportunities for machine vision systems globally.⁷

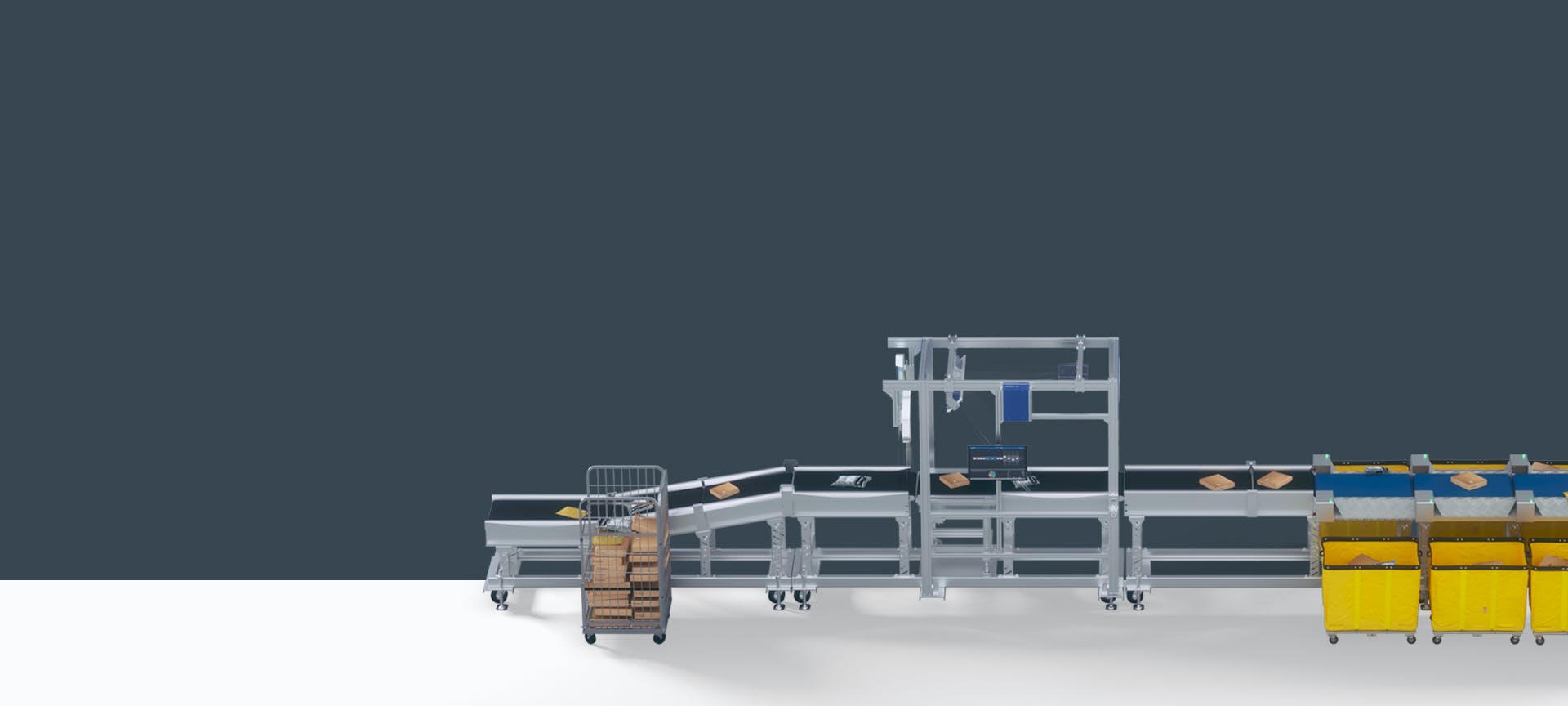

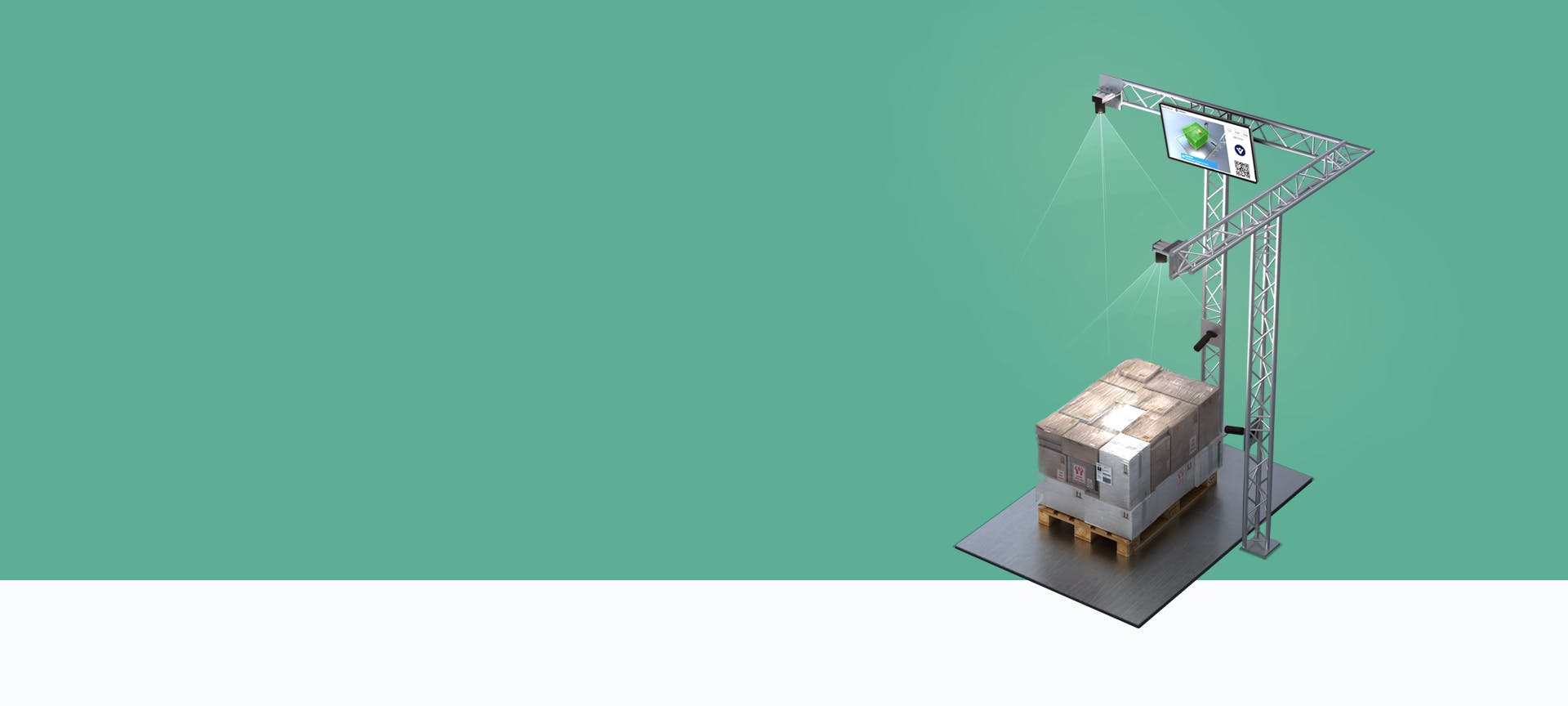

Especially in the logistics sector, depending on human capital can be a challenge. Machine vision systems provide more accuracy, faster handling and ensure a smooth process overall. By using suitable systems, companies can increase their throughput, secure transparent processes and tackle changing demands and high-pressure phases.⁸

The basis for optimizing logistics processes is always the automated capture of shipment data - fast, efficient and error-free. VITRONIC offers automated solutions for warehouse, distribution and e-commerce logistics, CEP industry and air freight. This includes systems for capturing shipment data such as codes, plain text, weight and dimensions. The data is captured on all shipments - whether it's a small, flat package, bagged goods, or a pallet. From automated support of manual sorting processes to fully integrated reading and sorting systems, VITRONIC offers solutions for every need, because requirements vary from region to region and company to company.

What to take from this?

With new challenges and a striving global economy, the logistics sector in the MEA region is set to grow to meet the demand from rising economies in the region. With an increase in population and buying power, logistics companies in the Middle East and Africa region face new challenges and must adapt new technologies to be ready for the future. One of these technologies certainly is machine vision. While currently manpower is relatively cheap and many companies rely on it to handle their demands, this is not a suitable model for the future. The future of logistics demands more accuracy, faster response rates and an overall readiness to handle large amounts of goods. Companies that invest in the systems now can make sure to keep the pace of projected future demand and to stay on top of the list. Companies who fail to adapt however might be in the situation of not being able to maintain the market position they have now.

Conclusion

In Short

- The MEA region gains importance as a logistics hub

- Growing challenges require new technologies

- Machine vision systems will be a game changer

- Rising personnel costs make automation indispensable

Summary

You can edit this slice directly in your code editor.