Menü

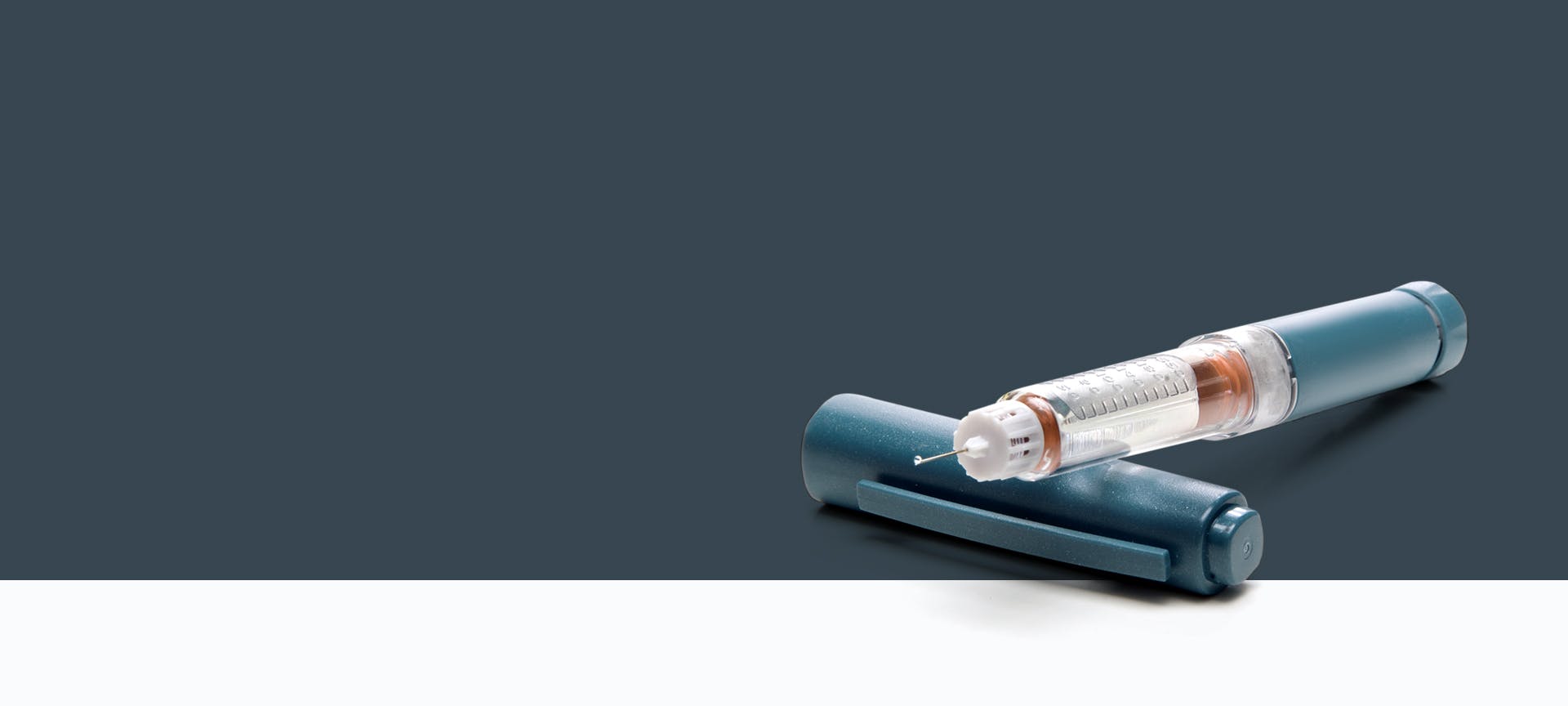

Vial Inspection Because Health Matters

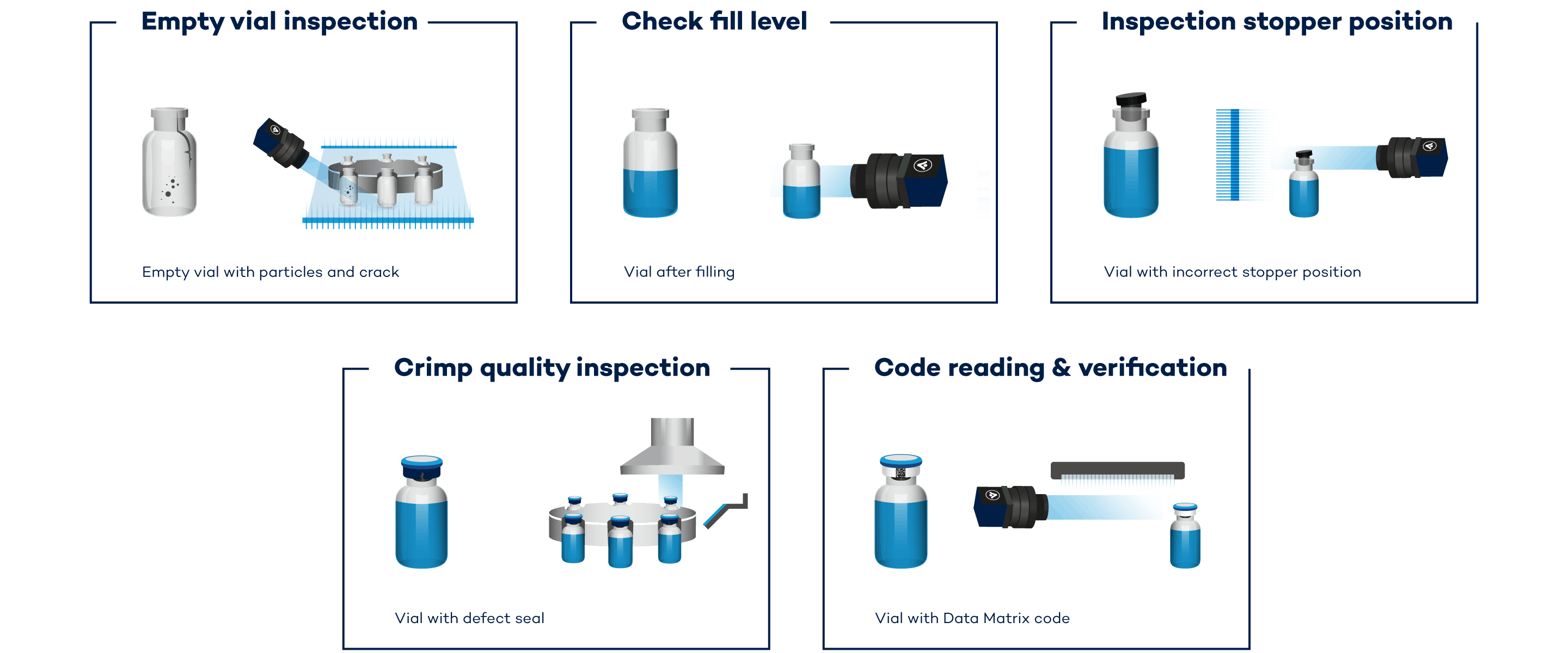

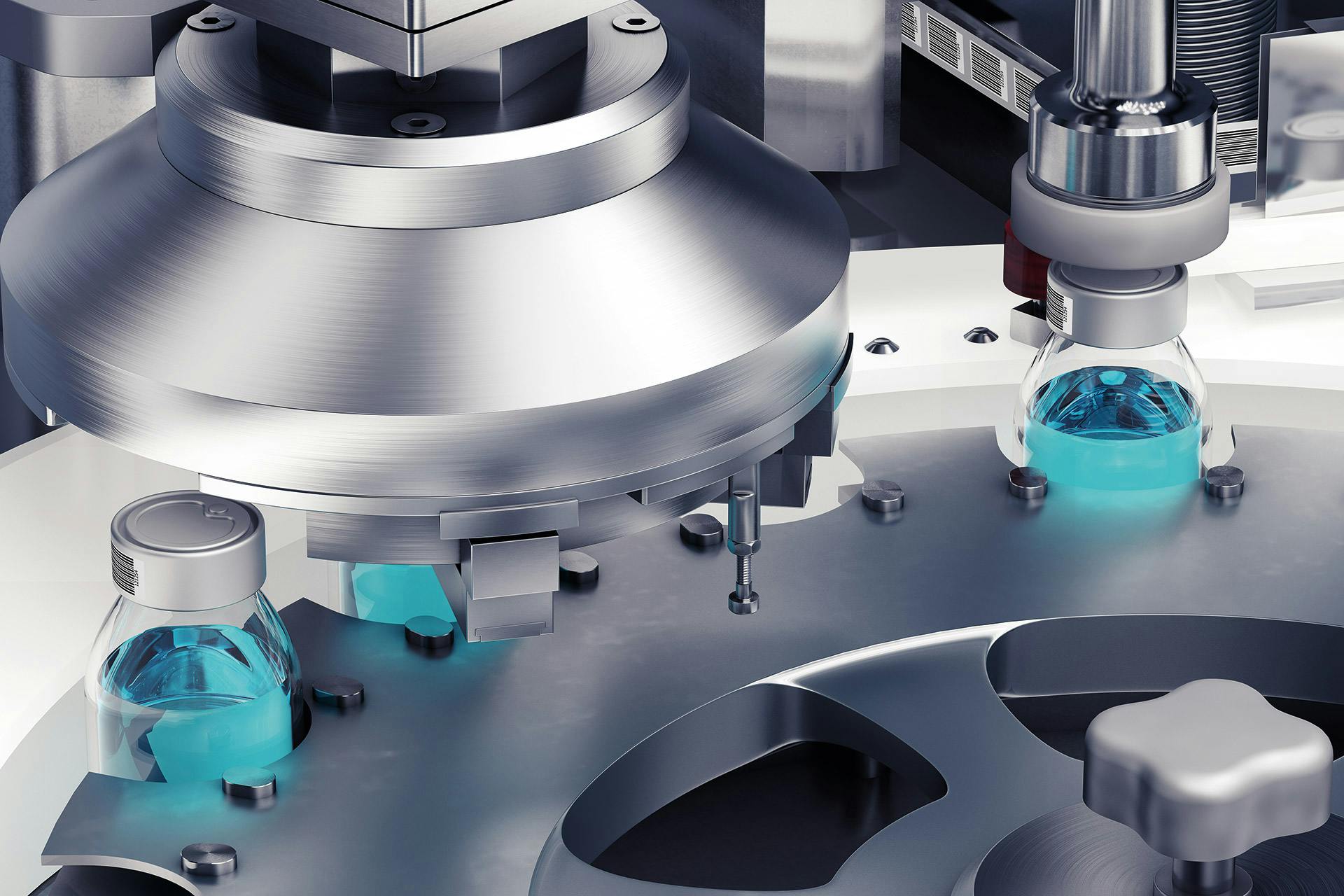

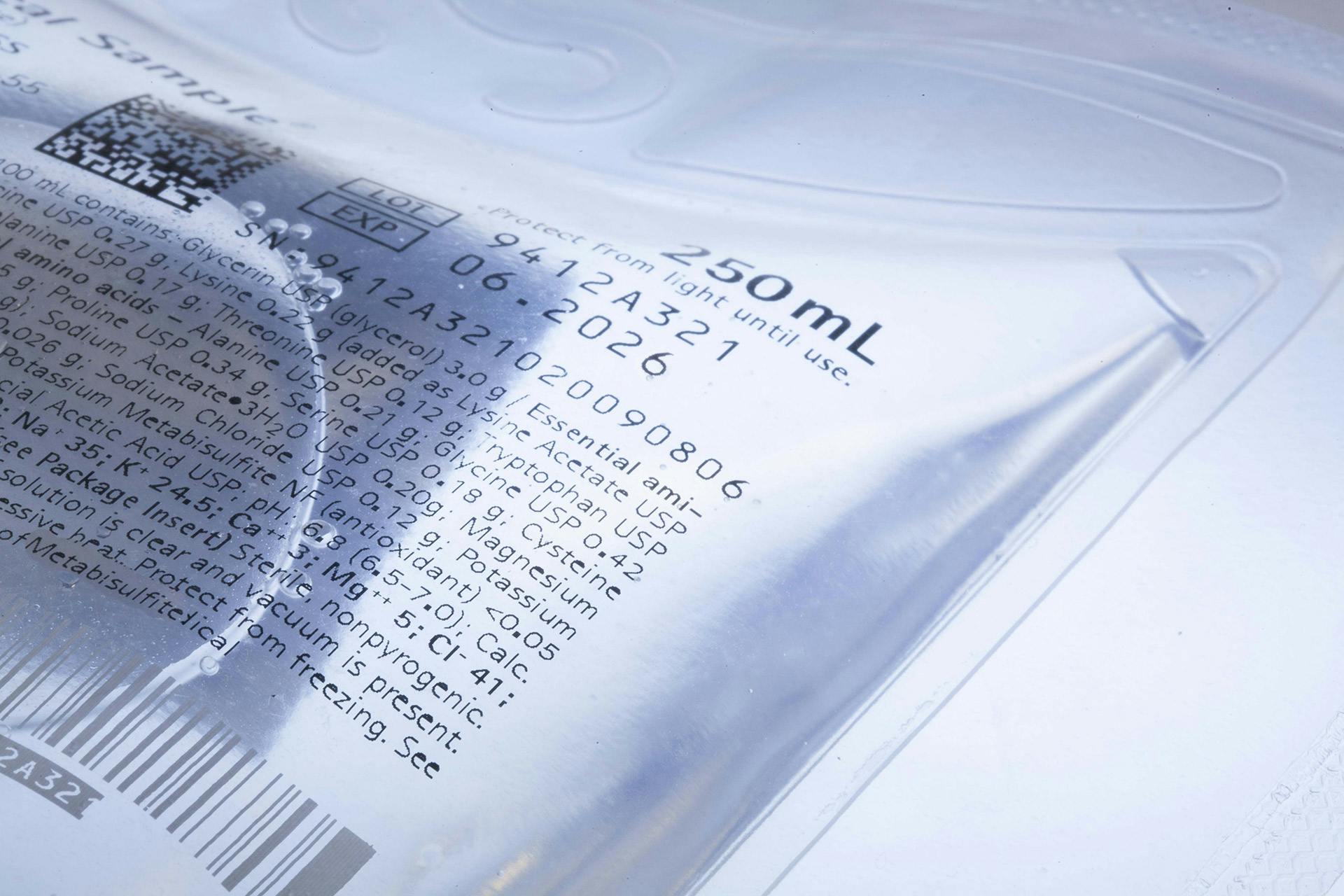

Maximum Product Safety in the Inspection of Vials and Seals

Vial Inspection

For Taking Away and Passing On

Brochure

VINSPEC HEALTHCARE—Inline Pharmaceutical/Medical Device Inspection

Brochure

VINSPEC HEALTHCARE - for Pharmaceutical Vials